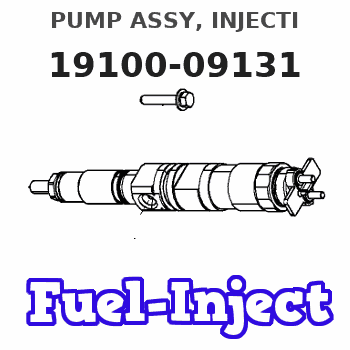

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-09131 |

| 002. | BODY ASSY, INJECTI | 09010-09730 |

| 003. | COVER, BEARING | 09020-10110 |

| 004. | TIMER ASSY, AUTOMA | 09180-03200 |

| 005. | PUMP ASSY, FUEL FE | 09210-02530 |

| 006. | COUPLING ASSY | 09250-00880 |

| 007. | GOVERNOR ASSY, MEC | 19080-03650 |

| 008. | FLYWEIGHT ASSY | 09084-00681 |

| 009. | LEVER SET | 09129-10101 |

Scheme ###:

| 000. | [01] | 19100-09131 | PUMP ASSY, INJECTI | 22010-6631 |

| 003. | [01] | 09180-03201 | TIMER ASSY, AUTOMA | 22510-2451A |

| 004. | [01] | 09210-02530 | PUMP ASSY, FUEL FE | 22570-1470A |

| 005. | [01] | 09250-00880 | COUPLING ASSY | |

| 006. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 007. | [01] | 09010-09730 | BODY ASSY, INJECTI | 22110-2850A |

| 008. | [01] | 19080-03650 | GOVERNOR ASSY, MEC | 22310-4790A |

| 011. | [01] | 94901-80710 | WASHER, COPPER PLA | 22863-1300A |

| 012. | [01] | 09001-80110 | COVER, CONTROL RAC | 22372-1130A |

| 013. | [01] | 09001-20340 | NUT, TIMER ROUND | |

| 014. | [08] | 94904-76890 | BOLT, W/WASHER | 22815-3210A |

| 015. | [02] | 09028-50030 | CAP | 22323-1210A |

Include in #3:

19100-09131

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-09131 | 22010-6631 | PUMP ASSY, INJECTI |

Information:

Disassembly, Inspection and Reassembly Of Cooling System

Water Pump

Inspection of Water Pump

Inspection of impeller and shaft rotation conditionIf the inspection of the impeller and shaft finds abnormal noise or rough rotation, replace the assembly.Thermostat

Disassembly of Thermostat

Inspection of Thermostat

Inspection of thermostatTo test the thermostat operation, immerse the thermostat in a container filled with water, and heat the water while measuring the water temperature. Record the temperature at which the valve starts to open and the temperature at which the valve lift becomes 8 mm [0.3 in.] or more. (a) Stir the water in the container to ensure uniform temperature distribution.(b) When installing the thermostat, be sure to check the valve opening temperature indication stamped on the upper face of the thermostat mounting flange.Overheating Warming Unit (Thermo Switch)

Inspection of Overheating Warming Unit

Overheating warming unit Immerse the temperature sensor in oil, and measure the resistance while increasing the oil temperature. If the temperature measurement exceeds the standard value significantly, replace the thermo switch.

Since the inspection requires heating of oil to high temperatures, be careful not to get burns or start a fire.

Installation of Cooling System

Installation of Cooling System

Water Pump

Inspection of Water Pump

Inspection of impeller and shaft rotation conditionIf the inspection of the impeller and shaft finds abnormal noise or rough rotation, replace the assembly.Thermostat

Disassembly of Thermostat

Inspection of Thermostat

Inspection of thermostatTo test the thermostat operation, immerse the thermostat in a container filled with water, and heat the water while measuring the water temperature. Record the temperature at which the valve starts to open and the temperature at which the valve lift becomes 8 mm [0.3 in.] or more. (a) Stir the water in the container to ensure uniform temperature distribution.(b) When installing the thermostat, be sure to check the valve opening temperature indication stamped on the upper face of the thermostat mounting flange.Overheating Warming Unit (Thermo Switch)

Inspection of Overheating Warming Unit

Overheating warming unit Immerse the temperature sensor in oil, and measure the resistance while increasing the oil temperature. If the temperature measurement exceeds the standard value significantly, replace the thermo switch.

Since the inspection requires heating of oil to high temperatures, be careful not to get burns or start a fire.

Installation of Cooling System

Installation of Cooling System