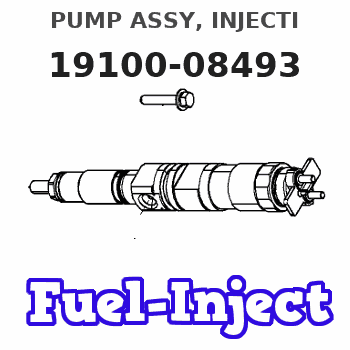

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-08493 |

| 002. | BODY ASSY, INJECTI | 09010-09190 |

| 003. | GOVERNOR ASSY, MEC | 09130-03193 |

| 004. | COVER ASSY, GOVERN | 09145-00223 |

| 005. | COMPENSATOR SUB-AS | 19260-00391 |

| 006. | TIMER ASSY, AUTOMA | 09180-02751 |

| 007. | PUMP ASSY, FUEL FE | 09210-02420 |

| 008. | PUMP ASSY, FUEL FE | 09210-02630 |

| 009. | PUMP ASSY, FUEL FE | 09210-03170 |

| 010. | COUPLING ASSY | 09250-00850 |

Scheme ###:

| 000. | [01] | 19100-08493 | PUMP ASSY, INJECTI | 22010-6362 |

| 003. | [01] | 09210-02420 | PUMP ASSY, FUEL FE | 22570-1430A |

| 003. | [01] | 09210-02630 | PUMP ASSY, FUEL FE | 22570-1500A |

| 003. | [01] | 09210-03170 | PUMP ASSY, FUEL FE | 22570-1730A |

| 004. | [01] | 09031-00380 | VALVE ASSY, OVERFL | 22107-1430A |

| 004. | [01] | 09031-00240 | VALVE ASSY, OVERFL | 22107-1290A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 007. | [05] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 009. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 012. | [01] | 09010-09190 | BODY ASSY, INJECTI | |

| 013. | [01] | 09250-00850 | COUPLING ASSY | 22610-1640A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09180-02751 | TIMER ASSY, AUTOMA | 22510-2390A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09130-03193 | GOVERNOR ASSY, MEC | |

| 018. | [01] | 09130-03194 | GOVERNOR ASSY, MEC | |

| 019. | [01] | 09039-10040 | CLIP, CORD | 22323-1190A |

Include in #3:

19100-08493

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-08493 | 22010-6362 | PUMP ASSY, INJECTI |

Information:

Measurement of Distortion of Cylinder Head Bottom Surface

Place a straight edge on the bottom surface of the cylinder head, measure the amount of surface distortion using feeler gages, and, if the limit value is exceeded, reface the surface with a surface grinder.

Measurement of distortion of cylinder head bottom surfaceMeasurement of Rocker Arm Inside Diameter and Rocker Shaft Diameter

Measure the inside diameter of the rocker arm (bushing) and the diameter of the rocker shaft to calculate the clearance between the rocker arm and shaft, and replace the rocker arm if the clearance is within the limit value. If the limit value is exceeded, replace the rocker arm and shaft.

Measurement of rocker arm inside diameter and rocker shaft diameterMeasurement of Valve Spring Perpendicularity and Free Length

Inspect each valve spring for perpendicularity and free length, and, if the limit value is exceeded, replace the valve.

Measurement of valve spring perpendicularity and free lengthMeasurement of Pushrod Deflection

If the pushrod defection exceeds the standard value, replace the pushrod. The standard value above is based on dial gage reading.

Measurement of pushrod deflectionMeasurement of Valve Stem Diameter

If the stem diameter exceeds the limit value, replace the valve stem. Also replace the valve stem if it is unevenly worn.

Measurement of valve stem diameterMeasurement of Clearance Between Valve Stem and Valve Guide

Measure the valve guide bore with and internal bore micrometer.Because the valve guide wears more rapidly at the upper and lower ends, measure the diameter at both ends in two crossing directions. If the limit is exceeded, replace worn parts. Remove carbon deposits from the valve and valve guide before measuring the clearance.

Measurement of valve guide inside diameter

Removal of valve guideReplacement of Valve Guides

(1) To remove the valve guides, use the valve guide remover. (2) To press-fit the valve guides, use the valve guide installer and a press.

Be sure to use the valve guide installer in order to drive the valve guide to the prescribed depth.

(3) After installing the valve guide, insert a new valve and check the smoothness of the movement.(4) When the valve guide is replaced, check the contact of the valve with the valve seat.

Installation of valve guideInspection of Valve Faces

Coat the valve face lightly with red lead, and use the valve lapper to inspect the valve contact with the valve seat. If the contact is not uniform and the valve is defective, or if a limit is exceeded, correct or replace the valve and valve seat.

Inspection of valve face (a) Inspect the valve face after the valve guide is inspected or replaced.(b) When pressing the valve coated with red lead against the valve seat, do not rotate the valve.(c) After the valve or valve seat is corrected or replaced, lap the valve against the valve seat.

Valve seat contact with seat

Valve contact with seatReplacement of Valve Seats

(1) Removal of valve seatWeld a stud or bar to the valve seat, insert a shaft into the valve guide bore from the top of the cylinder head, and drive the seat off the cylinder head. When welding

Place a straight edge on the bottom surface of the cylinder head, measure the amount of surface distortion using feeler gages, and, if the limit value is exceeded, reface the surface with a surface grinder.

Measurement of distortion of cylinder head bottom surfaceMeasurement of Rocker Arm Inside Diameter and Rocker Shaft Diameter

Measure the inside diameter of the rocker arm (bushing) and the diameter of the rocker shaft to calculate the clearance between the rocker arm and shaft, and replace the rocker arm if the clearance is within the limit value. If the limit value is exceeded, replace the rocker arm and shaft.

Measurement of rocker arm inside diameter and rocker shaft diameterMeasurement of Valve Spring Perpendicularity and Free Length

Inspect each valve spring for perpendicularity and free length, and, if the limit value is exceeded, replace the valve.

Measurement of valve spring perpendicularity and free lengthMeasurement of Pushrod Deflection

If the pushrod defection exceeds the standard value, replace the pushrod. The standard value above is based on dial gage reading.

Measurement of pushrod deflectionMeasurement of Valve Stem Diameter

If the stem diameter exceeds the limit value, replace the valve stem. Also replace the valve stem if it is unevenly worn.

Measurement of valve stem diameterMeasurement of Clearance Between Valve Stem and Valve Guide

Measure the valve guide bore with and internal bore micrometer.Because the valve guide wears more rapidly at the upper and lower ends, measure the diameter at both ends in two crossing directions. If the limit is exceeded, replace worn parts. Remove carbon deposits from the valve and valve guide before measuring the clearance.

Measurement of valve guide inside diameter

Removal of valve guideReplacement of Valve Guides

(1) To remove the valve guides, use the valve guide remover. (2) To press-fit the valve guides, use the valve guide installer and a press.

Be sure to use the valve guide installer in order to drive the valve guide to the prescribed depth.

(3) After installing the valve guide, insert a new valve and check the smoothness of the movement.(4) When the valve guide is replaced, check the contact of the valve with the valve seat.

Installation of valve guideInspection of Valve Faces

Coat the valve face lightly with red lead, and use the valve lapper to inspect the valve contact with the valve seat. If the contact is not uniform and the valve is defective, or if a limit is exceeded, correct or replace the valve and valve seat.

Inspection of valve face (a) Inspect the valve face after the valve guide is inspected or replaced.(b) When pressing the valve coated with red lead against the valve seat, do not rotate the valve.(c) After the valve or valve seat is corrected or replaced, lap the valve against the valve seat.

Valve seat contact with seat

Valve contact with seatReplacement of Valve Seats

(1) Removal of valve seatWeld a stud or bar to the valve seat, insert a shaft into the valve guide bore from the top of the cylinder head, and drive the seat off the cylinder head. When welding