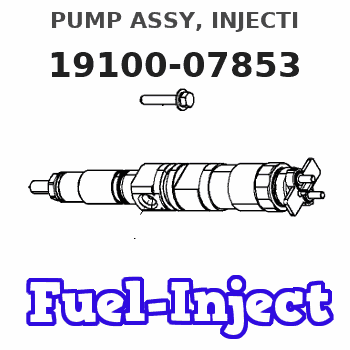

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-07853 |

| 002. | BODY ASSY, INJECTI | 09010-08850 |

| 003. | COVER, BEARING | 09020-10110 |

| 004. | TIMER ASSY, AUTOMA | 09180-02820 |

| 005. | PUMP ASSY, FUEL FE | 09210-01900 |

| 006. | COUPLING ASSY | 09250-00880 |

| 007. | GOVERNOR ASSY, MEC | 19080-02751 |

| 008. | FLYWEIGHT ASSY | 09084-00681 |

Scheme ###:

| 000. | [01] | 19100-07853 | PUMP ASSY, INJECTI | 22010-5992 |

| 003. | [01] | 09180-02821 | TIMER ASSY, AUTOMA | 22510-2181A |

| 004. | [01] | 09210-01900 | PUMP ASSY, FUEL FE | 22570-1330A |

| 005. | [01] | 09250-00880 | COUPLING ASSY | |

| 006. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 007. | [01] | 09010-08850 | BODY ASSY, INJECTI | |

| 008. | [01] | 19080-02752 | GOVERNOR ASSY, MEC | |

| 008. | [01] | 19080-02751 | GOVERNOR ASSY, MEC | |

| 011. | [01] | 94901-81820 | WASHER, COPPER PLA | 22847-2050A |

| 012. | [01] | 13650-00070 | SENSOR ASSY, POSIT | 21180-1480A |

| 013. | [01] | 09001-20340 | NUT, TIMER ROUND | |

| 014. | [08] | 94904-44010 | BOLT | |

| 014. | [04] | 94904-76890 | BOLT, W/WASHER | 22815-3210A |

| 015. | [02] | 09028-50030 | CAP | 22323-1210A |

| 017. | [01] | 09039-10011 | CLIP, CORD | 22131-1231A |

| 018. | [01] | 91418-06101 | BOLT, W/WASHER | 22815-2660A |

| 019. | [01] | 94935-01980 | CLIP, CORD | 22682-1010A |

| 020. | [02] | 91418-06121 | BOLT, W/WASHER | 22815-1500A |

| 021. | [01] | 91160-05041 | NUT, HEXAGON | 22456-1020A |

| 022. | [01] | 91410-05121 | BOLT, W/WASHER | 22815-2650A |

| 023. | [ C] | 94901-38470 | WASHER, PLATE, SK | |

| 023. | [ C] | 94901-37660 | WASHER, PLATE, SK | 22885-5670A |

| 023. | [ C] | 94901-37650 | WASHER, PLATE, SK | 22885-5660A |

| 023. | [ C] | 94901-37640 | WASHER, PLATE, SK | 22885-5650A |

| 023. | [ C] | 94901-37630 | WASHER, PLATE, SK | 22885-5640A |

| 024. | [01] | 94905-03540 | NUT, HEXAGON | 22825-2010A |

| 025. | [01] | 09558-90010 | TUBE | |

| 026. | [01] | 09008-90140 | BRACKET | 22343-2840A |

| 027. | [08] | 94901-36520 | WASHER, PLATE, SK |

Include in #3:

19100-07853

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-07853 | 22010-5992 | PUMP ASSY, INJECTI |

Information:

Oil seal driving tool Driving Seals onto Shaft:(a) Coat the seal lip with grease.(b) Use a seal guide like the one shown in the drawing when the shaft has steps, splines, threads or keyways.

Oil seal guide1.2 O-RingsUse a guide when it is necessary to move O-rings over steps, splines, threads or keyways to install them. Apply a light coat of grease to O-rings before fitting them.

O-ring guide1.3 Bearings(1) When driving bearings into place, be sure to tap the race that is being fitted. (If the inner race is being fitted, tap the inner race. Likewise, if it is the outer race that is being fitted, tap the outer race.) Use fitting tools like the one shown in the drawing that are appropriate for inner or outer races.

Bearing fitting tool(2) Bearings are best fitted using a press as shock loads and errors can be minimized.

Fitting bearing using a press1.4 Lock PlatesAlways bend lock plates properly. The drawing on the right shows some of typical lock plates being bent properly and improperly.1.5 Split Pins and Spring PinsAs a rule, all split pins must be replaced with new ones after each removal. It is also important to bend split pins properly. Spring pins must be driven into place completely.

Typical locking plates with good and bad bends