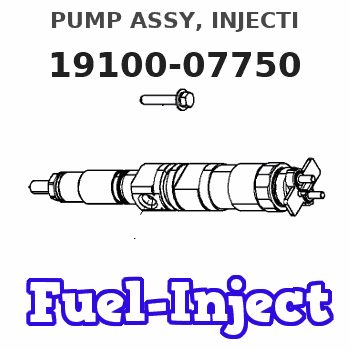

Information pump assy, injecti

Nozzle:

0935003890

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Governor assy, mec | 1908900271 |

| Timer assy, automa | No Application |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-07750 |

| 002. | BODY ASSY, INJECTI | 09010-08040 |

| 003. | COVER, BEARING | 09020-10250 |

| 004. | GOVERNOR ASSY, MEC | 09130-03110 |

| 005. | COVER ASSY, GOVERN | 09145-00133 |

| 006. | TIMER ASSY, AUTOMA | 09180-02551 |

| 007. | PUMP ASSY, FUEL FE | 09210-03170 |

| 008. | COUPLING ASSY | 09250-00801 |

Scheme ###:

| 000. | [01] | 19100-07750 | PUMP ASSY, INJECTI | 22010-6040 |

| 004. | [01] | 09031-00240 | VALVE ASSY, OVERFL | 22107-1290A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 007. | [05] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 009. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 010. | [01] | 09028-50030 | CAP | 22323-1210A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 013. | [01] | 09250-00801 | COUPLING ASSY | 22610-1620A |

| 014. | [01] | 09180-02551 | TIMER ASSY, AUTOMA | |

| 015. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09010-08040 | BODY ASSY, INJECTI | 22110-2380A |

| 021. | [01] | 09210-03170 | PUMP ASSY, FUEL FE | 22570-1730A |

| 022. | [01] | 09039-10040 | CLIP, CORD | 22323-1190A |

| 023. | [01] | 09130-03110 | GOVERNOR ASSY, MEC |

Include in #3:

19100-07750

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-07750 | 22010-6040 | PUMP ASSY, INJECTI | |

| 22010-6040 | HINO | PUMP ASSY, INJECTI |

Information:

ENGINE OIL AND OIL FILTER

1. Engine oil specifications Use oils that meet the Engine Service Classification CC.2 Oil level check(1) Check the crankcase oil level with a dipstick with the engine kept level.(2) If the oil level is at or below "L" (low level) mark on the dipstick, add oil to "H" (high level) mark on the dipstick. a) After adding oil, leave the engine standing for one minute and check the oil level.b) Avoid mixing different brands of oils. In some cases, they are not compatible with each other and deteriorate when mixed. Use the same brand at successive intervals. c) If the engine has been left standing for a long period of time, check the oil for level and contamination before starting the engine. Start and run the engine for a few minutes. Then stop the engine and check the oil level again.Recommended engine oil viscosities

Checking oil level3. Oil change (1) Change the oil after the first 50 service hours of operation of a new or reconditioned engine and every 100 service hours thereafter.(2) Warm up the engine. Remove the drain plug and allow the oil to drain in a container. Install the drain plug, tightening it to the specified torque, and refill the engine with new oil.(3) Refill to the "H" mark on the dipstick. Approximately 0.5 liter (0.5 qt) of oil is required for the oil filter and oil lines. 4. Oil filter change

Removing used oil filter(1) Change the oil filter every 100 service hours.(2) Remove the used filter with a filter wrench. Discard the filter. (3) Remove all of the old filter gasket from the filter base and apply a thin coat of engine oil to the gasket on the new filter. Install the filter by hand until its gasket contacts the base. Tighten 3/4 turn more.

Do not cause damage to the O-ring when installing the filter.

(4) Add 0.5 liter (0.5 qt) of oil.(5) Start the engine and check for leaks around the filter. (6) Stop the engine. Check the oil level and add oil if necessary.

Installing new oil filterVALVE CLEARANCE

Make an adjustment to the valve clearance when the engine is cold.(1) Slightly loosen the cylinder head bolts and retighten them to the specified torque in number sequence.

Cylinder head bolt tightening sequence(2) Find top dead center compression position for No. 1 piston by using the procedure that follows: (a) Turn the crankshaft until TDC mark on the crankshaft pulley is aligned with the mark on the timing gear case. (b) With No. 1 piston at top dead center on the compression stroke, the rocker arms will not be moved when the crankshaft is turned approximately 20° in both directions. (c) If the rocker arms move, No. 1 piston is at top dead center on the intake or exhaust stroke. In such a case, turn the crankshaft 360° in the direction of engine rotation again. No. 1 piston is now at top dead center on the compression stroke. (3) Loosen the lock nut for

1. Engine oil specifications Use oils that meet the Engine Service Classification CC.2 Oil level check(1) Check the crankcase oil level with a dipstick with the engine kept level.(2) If the oil level is at or below "L" (low level) mark on the dipstick, add oil to "H" (high level) mark on the dipstick. a) After adding oil, leave the engine standing for one minute and check the oil level.b) Avoid mixing different brands of oils. In some cases, they are not compatible with each other and deteriorate when mixed. Use the same brand at successive intervals. c) If the engine has been left standing for a long period of time, check the oil for level and contamination before starting the engine. Start and run the engine for a few minutes. Then stop the engine and check the oil level again.Recommended engine oil viscosities

Checking oil level3. Oil change (1) Change the oil after the first 50 service hours of operation of a new or reconditioned engine and every 100 service hours thereafter.(2) Warm up the engine. Remove the drain plug and allow the oil to drain in a container. Install the drain plug, tightening it to the specified torque, and refill the engine with new oil.(3) Refill to the "H" mark on the dipstick. Approximately 0.5 liter (0.5 qt) of oil is required for the oil filter and oil lines. 4. Oil filter change

Removing used oil filter(1) Change the oil filter every 100 service hours.(2) Remove the used filter with a filter wrench. Discard the filter. (3) Remove all of the old filter gasket from the filter base and apply a thin coat of engine oil to the gasket on the new filter. Install the filter by hand until its gasket contacts the base. Tighten 3/4 turn more.

Do not cause damage to the O-ring when installing the filter.

(4) Add 0.5 liter (0.5 qt) of oil.(5) Start the engine and check for leaks around the filter. (6) Stop the engine. Check the oil level and add oil if necessary.

Installing new oil filterVALVE CLEARANCE

Make an adjustment to the valve clearance when the engine is cold.(1) Slightly loosen the cylinder head bolts and retighten them to the specified torque in number sequence.

Cylinder head bolt tightening sequence(2) Find top dead center compression position for No. 1 piston by using the procedure that follows: (a) Turn the crankshaft until TDC mark on the crankshaft pulley is aligned with the mark on the timing gear case. (b) With No. 1 piston at top dead center on the compression stroke, the rocker arms will not be moved when the crankshaft is turned approximately 20° in both directions. (c) If the rocker arms move, No. 1 piston is at top dead center on the intake or exhaust stroke. In such a case, turn the crankshaft 360° in the direction of engine rotation again. No. 1 piston is now at top dead center on the compression stroke. (3) Loosen the lock nut for