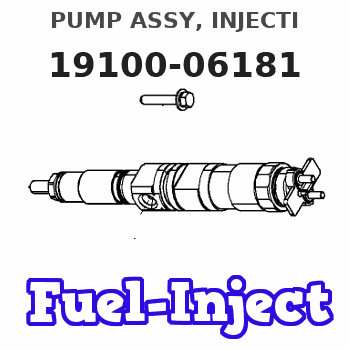

Information pump assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 19100-06181 | PUMP ASSY, INJECTI | 22030-2330 |

| 004. | [01] | 09031-00240 | VALVE ASSY, OVERFL | 22107-1290A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 008. | [01] | 91418-06141 | BOLT, W/WASHER | 22815-1480A |

| 008. | [01] | 91518-06121 | BOLT, W/WASHER | 22815-2740A |

| 009. | [01] | 09006-00150 | COVER SUB-ASSY, TI | 22825-1470A |

| 010. | [05] | 91418-06161 | BOLT, W/WASHER | 22815-1380A |

| 011. | [01] | 91518-08221 | BOLT, W/WASHER | 22815-1190A |

| 012. | [04] | 90258-08001 | WASHER, SPRING | 22877-1720A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09255-10420 | BLOCK, COUPLING | 22630-1030A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09010-08030 | BODY ASSY, INJECTI | 22110-2620A |

| 021. | [01] | 09210-01510 | PUMP ASSY, FUEL FE | 22570-1240A |

| 022. | [04] | 09241-70060 | WASHER, COUPLING S | 22867-1490A |

| 023. | [01] | 19080-01691 | GOVERNOR ASSY, MEC | 22330-2200 |

| 027. | [04] | 91266-10081 | NUT, HEXAGON | 22825-1490A |

| 028. | [04] | 90258-10001 | WASHER, SPRING | 28219-1120A |

| 029. | [04] | 94901-15020 | WASHER, STEEL PLAT | 22877-1551A |

| 030. | [04] | 94904-04870 | BOLT, HEXAGON | 22815-2380A |

Include in #3:

19100-06181

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-06181 | 22030-2330 | PUMP ASSY, INJECTI |

Information:

Illustration 1. 173-1530 Injector Seating Tool Group. See Chart A for item identification and part numbers. MUI Engine Procedure

This procedure can be used for 3114, 3116, and 3126 MUI Engines.1. Install a new injector brass sleeve or inspect and ream the existing sleeves as outlined in Tool Operating Manual NEHS0675. It is not necessary to ream new sleeves when using this procedure.2. Install the unit injector and align the rack bar. Do not use the small O-ring on the injector tip.3. Install holding clamp bolt (12) and tighten to 12 3 N m, 1.2 0.3 meter kg, (9 2 lb. ft.).

Illustration 2. Install Holding Clamp Bolt (12).4. Remove inlet manifold bolt (13) closest to the injector.

For a repair procedure, remove only one manifold bolt at a time. Removing all the manifold bolts could weaken or damage the manifold/head gasket material.

Illustration 3. Remove Inlet Manifold Bolt (13).5. Install MUI injector forcing cover (7) over the injector. The milled surface should line up with injector clamp bolt. The two long flat surfaces are for valve spring clearance. Refer to the "MUI Tooling" section for a warning on the sharp edges of this tool.

Make sure the slots of injector forcing cover (7) are free of nicks, scratches, or burrs. Damage in the slots will result in damage to the injector spring.

Illustration 4. Install Injector Forcing Cover.

Illustration 5. MUI Injector Forcing Cover Properly Installed.6. If assembled, back out forcing bolt (4) in forcing bridge (1) to provide clearance between the injector forcing cover and forcing bridge.7. Place a small amount of 4C-5591 Thread Lubricant on top of the injector forcing cover's wear button (10) and on the threads of forcing bolt (4).

Complete lubrication of the wear button and forcing bolt must be maintained for each injector seating procedure. Failure to relubricate each part before seating the next injector may cause premature wear or tool damage. Also, make sure the forcing bolt turns freely and does not have any damaged threads.

8. Install the forcing bridge with three 7X-0457 Bolts (5) and three 9M-1974 Hard Washers (6). Put the two long legs of the forcing bridge in the two rocker arm shaft support holes closest to the injector. The short leg of the forcing bridge with spacer (2) installed sits on the intake manifold bolt boss. [The long spacer (3) is used when the manifold is not installed.]

Illustration 6. Install Forcing Bridge.(1) MUI Forcing Bridge.(2) Short spacer leg.(5) 7X-0457 Hex Head Bolt.(6) 9M-1974 Hard Washer

Do not install the injectors "off-engine" because the injector tip will protrude from the head and be subject to damage. If the injectors are installed off-engine, make sure the bottom surface of the head is raised off the surface of the work bench.

9. Tighten forcing bridge mounting bolts (5) to 28 7 N m, 2.9 0.7 meter kg, (21 5 lb. ft.).

Damage to the head could occur if bridge mounting bolts (5) are not tightened to the specified torque.

Illustration 7. Install Forcing Bolt (4).10.