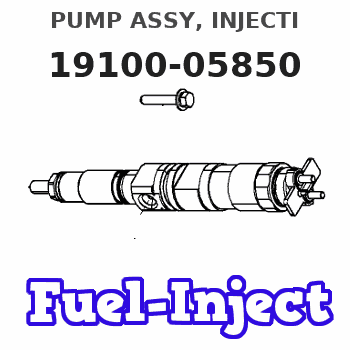

Information pump assy, injecti

Nozzle:

0935002080

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Timer assy, automa | 0918030060 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900210 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-05850 |

| 002. | BODY ASSY, INJECTI | 09010-04232 |

| 003. | COVER, BEARING | 09020-10410 |

| 004. | TIMER ASSY, AUTOMA | 09180-01210 |

| 005. | PUMP ASSY, FUEL FE | 09210-00920 |

| 006. | COUPLING ASSY | 09250-00270 |

| 007. | GOVERNOR ASSY, MEC | 19080-01620 |

Scheme ###:

| 000. | [01] | 19100-05850 | PUMP ASSY, INJECTI | 22010-5500 |

| 004. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 007. | [06] | 94904-71150 | BOLT, W/WASHER | 6 306 1001 00 |

| 008. | [01] | 09010-04232 | BODY ASSY, INJECTI | 22110-1590C |

| 009. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 010. | [01] | 19080-01620 | GOVERNOR ASSY, MEC | 22310-3800A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 012. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 013. | [01] | 09250-00270 | COUPLING ASSY | 22610-1080A |

| 014. | [01] | 09001-20180 | NUT, TIMER ROUND | 22511-1070A |

| 015. | [01] | 09180-01210 | TIMER ASSY, AUTOMA | 22510-1190A |

| 016. | [01] | 94901-50590 | WASHER, SPRING | 22877-1620A |

| 017. | [02] | 09028-50030 | CAP | 22323-1210A |

Include in #3:

19100-05850

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-05850 | 22010-5500 | PUMP ASSY, INJECTI | |

| 22010-5500 | HINO | PUMP ASSY, INJECTI |

Information:

Structure And Operation

Air Cleaner

* The air cleaner is a single element type.* The air cleaner is provided with a vacuator valve.* When the engine speed drops below a specified level, the vacuator valve is shaken by a consequent change in internal vacuum to automatically force out accumulated water and dust.Turbocharger

Waste Gate Mechanism

* The waste gate mechanism allows excess exhaust gas to escape from the turbocharger by means of an actuator in order to maintain the boost pressure at an appropriate level. This prevents overrunning of the turbocharger and excessive pressure buildups in the intake manifold.* The boost pressure is led via a rubber hose from the compressor cover to chamber A in the actuator. When the boost pressure in chamber A is less than the predetermined value, the actuator does not function and the waste gate valve remains closed. All exhaust gas then flows toward the turbine wheel. * When the boost pressure in chamber A exceeds the predetermined value, the waste gate valve opens, reducing the amount of exhaust gas flowing toward the turbine wheel. As a result, the speed of the compressor wheel, and thus the boost pressure, are reduced.Operating of Over-Boost Valve

* Over-boost valve operates when the boost pressure increases abnormally because of faulty operation of the waste gate mechanism.* If boost pressure of over-boost valve increases to become higher than the present value, the excessive boost pressure is discharged into the atmosphere, protecting the engine from excessive boost pressure. When the valve is operating, a pipe-blowing sound is generated. Troubleshooting

General Inspection And Adjustment

Cleaning And Inspection Of Air Cleaner Element

[Cleaning] * Blow a jet of compressed air at a pressure not higher than 685 kPa {7 kgf/cm2} against the inside surfaces of the element.* Move the compressed air jet up and down along all pleats of the filter paper element.

* For the frequency and timing of cleaning, refer to the relevant instruction manual. More frequent cleaning than necessary could damage the element or cause dust and foreign matter to be sucked into the engine.* Do not strike the element or hit it against another object to remove dust.* Do not blow compressed air against outside surfaces of the element. [Inspection] * Shine some electric light inside the element.* Replace the element if thin spots or broken parts are evident in the filter paper, or if the packing at the top of the element is damaged. Also replace the element if the dust on the element is damp with oily smoke or soot, regardless of the replacement schedule.Inspection Of Intake Manifold For Looseness

* Check the intake manifold and air inlet pipe mounting bolts and nuts

Air Cleaner

* The air cleaner is a single element type.* The air cleaner is provided with a vacuator valve.* When the engine speed drops below a specified level, the vacuator valve is shaken by a consequent change in internal vacuum to automatically force out accumulated water and dust.Turbocharger

Waste Gate Mechanism

* The waste gate mechanism allows excess exhaust gas to escape from the turbocharger by means of an actuator in order to maintain the boost pressure at an appropriate level. This prevents overrunning of the turbocharger and excessive pressure buildups in the intake manifold.* The boost pressure is led via a rubber hose from the compressor cover to chamber A in the actuator. When the boost pressure in chamber A is less than the predetermined value, the actuator does not function and the waste gate valve remains closed. All exhaust gas then flows toward the turbine wheel. * When the boost pressure in chamber A exceeds the predetermined value, the waste gate valve opens, reducing the amount of exhaust gas flowing toward the turbine wheel. As a result, the speed of the compressor wheel, and thus the boost pressure, are reduced.Operating of Over-Boost Valve

* Over-boost valve operates when the boost pressure increases abnormally because of faulty operation of the waste gate mechanism.* If boost pressure of over-boost valve increases to become higher than the present value, the excessive boost pressure is discharged into the atmosphere, protecting the engine from excessive boost pressure. When the valve is operating, a pipe-blowing sound is generated. Troubleshooting

General Inspection And Adjustment

Cleaning And Inspection Of Air Cleaner Element

[Cleaning] * Blow a jet of compressed air at a pressure not higher than 685 kPa {7 kgf/cm2} against the inside surfaces of the element.* Move the compressed air jet up and down along all pleats of the filter paper element.

* For the frequency and timing of cleaning, refer to the relevant instruction manual. More frequent cleaning than necessary could damage the element or cause dust and foreign matter to be sucked into the engine.* Do not strike the element or hit it against another object to remove dust.* Do not blow compressed air against outside surfaces of the element. [Inspection] * Shine some electric light inside the element.* Replace the element if thin spots or broken parts are evident in the filter paper, or if the packing at the top of the element is damaged. Also replace the element if the dust on the element is damp with oily smoke or soot, regardless of the replacement schedule.Inspection Of Intake Manifold For Looseness

* Check the intake manifold and air inlet pipe mounting bolts and nuts