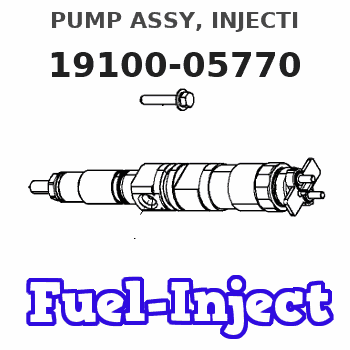

Information pump assy, injecti

Nozzle:

0935002080

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Timer assy, automa | 0918030060 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900190 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-05770 |

| 002. | BODY ASSY, INJECTI | 09010-03922 |

| 003. | COVER, BEARING | 09020-10410 |

| 004. | TIMER ASSY, AUTOMA | 09180-01210 |

| 005. | PUMP ASSY, FUEL FE | 09210-00920 |

| 006. | COUPLING ASSY | 09250-00270 |

| 007. | GOVERNOR ASSY, MEC | 19080-01550 |

| 008. | SWITCH KIT, CONTRO | 09009-90390 |

Scheme ###:

| 000. | [01] | 19100-05770 | PUMP ASSY, INJECTI | 22010-5430 |

| 000. | [01] | 19100-05770 | PUMP ASSY, INJECTI | S2201-05430 |

| 005. | [01] | 09010-03922 | BODY ASSY, INJECTI | 22110-1590A |

| 006. | [01] | 19080-01550 | GOVERNOR ASSY, MEC | 22310-3760A |

| 007. | [06] | 94904-70620 | BOLT, W/WASHER | 22815-1620A |

| 008. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 010. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 011. | [01] | 09180-01210 | TIMER ASSY, AUTOMA | 22510-1190A |

| 012. | [01] | 09001-20180 | NUT, TIMER ROUND | 22511-1070A |

| 013. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 014. | [01] | 94901-50590 | WASHER, SPRING | 22877-1620A |

| 015. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 017. | [01] | 09250-00270 | COUPLING ASSY | 22610-1080A |

| 018. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 020. | [02] | 94901-02480 | WASHER | 22847-1940A |

Include in #3:

19100-05770

as PUMP ASSY, INJECTI

19100-05770

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-05770 | 22010-5430 | PUMP ASSY, INJECTI | |

| 22010-5430 | HINO | PUMP ASSY, INJECTI | |

| S2201-05430 | HINO | PUMP ASSY, INJECTI |

Information:

To Stop the Engine

A spring loaded stop control is usually situated near the normal engine controls and it is only necessary to pull out the stop control until the engine ceases to rotate. Ensure the engine movement has completely stopped before returning the control to the normal running condition. Turn the starter switch to the "O" position.Some engines may have an electric solenoid stop control on the fuel injection pump operated by a switch on the control panel.Cold Starting Aid; Using the Starting Aid

C1 1. Off Position2. Run Position3. Heat Position4. Heat and Start PositionTo start the engine, proceed as follows:-Ensure engine stop control is pushed fully home.Turn starter switch (Fig. C.1) to the "H" position and hold it there for fifteen to twenty seconds.With the accelerator in the fully open position, turn the starter switch to the "HS" position thereby engaging the starter motor.If the engine does not start within fifteen seconds, return the switch to the "H" position for ten seconds and then re-engage the starter motor by switching to the "HS" position.As soon as the engine starts, the switch should be returned to the "R" position.Earlier Heat Start Switch

C2 1. Off2. Start3. Heat4. Heat and StartThe cold start switch fitted to earlier engines is shown in Fig. C.2.Where this type of switch is used, it is customary to have a separate switch for the electrical circuits and this should be turned on before starting the engine and turned off after stopping the engine.Things to Note

Ensure that the electrical connection to the cold starting aid is correctly made.In the event of difficult starting, check that fuel is reaching the cold starting aid in the induction manifold by unscrewing the inlet fuel connection. If fuel is reaching it satisfactorily, then it may be that the cold starting aid itself is not working correctly. This can be checked by removing the air cleaner and watching the cold starting aid whilst the equipment is used. When the starting switch is turned to the "heat" position, the element should become red hot, and on engagement of the starter motor, ignition of the fuel should take place. The engines are fitted with efficient cold starting equipment and no responsibility can be accepted for any damage caused by unauthorised starting aids.Running In

It is not necessary to gradually run-in a new or factory rebuilt engine and any prolonged light load running during the early life of the engine can in fact prove harmful to the bedding in of piston rings and liners.Full load can be applied on a new or factory rebuilt engine as soon as the engine is used, provided that the engine is first allowed to reach a temperature of at least 140°F (60°C).Preventive Maintenance

Whilst we have given specific periods for preventive maintenance, you should have due regard for the local regulations concerning your vehicle or machine and ensure that the engine is operating within those regulations.The time period for cleaning the oil bath type air cleaner or the renewing of

A spring loaded stop control is usually situated near the normal engine controls and it is only necessary to pull out the stop control until the engine ceases to rotate. Ensure the engine movement has completely stopped before returning the control to the normal running condition. Turn the starter switch to the "O" position.Some engines may have an electric solenoid stop control on the fuel injection pump operated by a switch on the control panel.Cold Starting Aid; Using the Starting Aid

C1 1. Off Position2. Run Position3. Heat Position4. Heat and Start PositionTo start the engine, proceed as follows:-Ensure engine stop control is pushed fully home.Turn starter switch (Fig. C.1) to the "H" position and hold it there for fifteen to twenty seconds.With the accelerator in the fully open position, turn the starter switch to the "HS" position thereby engaging the starter motor.If the engine does not start within fifteen seconds, return the switch to the "H" position for ten seconds and then re-engage the starter motor by switching to the "HS" position.As soon as the engine starts, the switch should be returned to the "R" position.Earlier Heat Start Switch

C2 1. Off2. Start3. Heat4. Heat and StartThe cold start switch fitted to earlier engines is shown in Fig. C.2.Where this type of switch is used, it is customary to have a separate switch for the electrical circuits and this should be turned on before starting the engine and turned off after stopping the engine.Things to Note

Ensure that the electrical connection to the cold starting aid is correctly made.In the event of difficult starting, check that fuel is reaching the cold starting aid in the induction manifold by unscrewing the inlet fuel connection. If fuel is reaching it satisfactorily, then it may be that the cold starting aid itself is not working correctly. This can be checked by removing the air cleaner and watching the cold starting aid whilst the equipment is used. When the starting switch is turned to the "heat" position, the element should become red hot, and on engagement of the starter motor, ignition of the fuel should take place. The engines are fitted with efficient cold starting equipment and no responsibility can be accepted for any damage caused by unauthorised starting aids.Running In

It is not necessary to gradually run-in a new or factory rebuilt engine and any prolonged light load running during the early life of the engine can in fact prove harmful to the bedding in of piston rings and liners.Full load can be applied on a new or factory rebuilt engine as soon as the engine is used, provided that the engine is first allowed to reach a temperature of at least 140°F (60°C).Preventive Maintenance

Whilst we have given specific periods for preventive maintenance, you should have due regard for the local regulations concerning your vehicle or machine and ensure that the engine is operating within those regulations.The time period for cleaning the oil bath type air cleaner or the renewing of