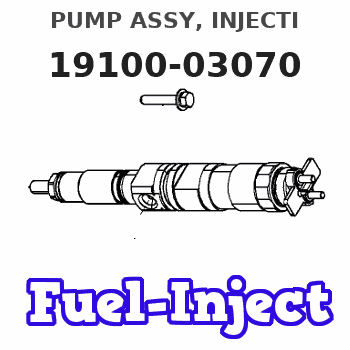

Information pump assy, injecti

Nozzle:

0935002890

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Governor assy, mec | 1908900271 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-03070 |

| 002. | BODY ASSY, INJECTI | 09010-06080 |

| 003. | GOVERNOR ASSY, MEC | 09130-01711 |

| 004. | COVER ASSY, GOVERN | 09145-00232 |

| 005. | PUMP ASSY, FUEL FE | 09210-01700 |

Scheme ###:

| 000. | [01] | 19100-03070 | PUMP ASSY, INJECTI | 22100-58341 |

| 001. | [01] | 09010-06080 | BODY ASSY, INJECTI | 22120-58340 |

| 002. | [01] | 09130-01711 | GOVERNOR ASSY, MEC | 22410-58343 |

| 003. | [01] | 09210-01700 | PUMP ASSY, FUEL FE | 22510-873 |

| 008. | [01] | 09001-80090 | COVER, CONTROL RAC | 22116-56230 |

| 009. | [01] | 09257-50170 | SHAFT, SPLINE | 22174-58201 |

| 010. | [01] | 09001-20190 | NUT, TIMER ROUND | 22611-58200 |

| 011. | [01] | 94901-50590 | WASHER, SPRING | 90099-01449 |

| 012. | [01] | 94913-00210 | KEY, WOODRUFF | 90099-13023 |

| 016. | [01] | 91418-06201 | BOLT, W/WASHER | 90091-20608 |

| 017. | [04] | 94904-72690 | BOLT, W/WASHER | 90099-04319 |

| 018. | [01] | 94904-72990 | BOLT, W/WASHER | 90099-04320 |

| 019. | [01] | 94904-73910 | BOLT, W/WASHER | 90099-04346 |

Include in #3:

19100-03070

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-03070 | 22100-5834 | PUMP ASSY, INJECTI | |

| 22100-58341 | TOYOTA | PUMP ASSY, INJECTI |

Information:

Introduction

This Special Instruction covers the procedure to install a wall flow Diesel Particulate Matter (DPM) filter on the above serial numbered Load Haul Dump Machines. This supplemental product support literature should be used with the appropriate Service Manual and the appropriate Parts Manual that is available for this standard machine.Read the entire Special Instruction. Understand the information before you perform any procedures. Understand the information before you order any parts.Safety Section

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive.Ensure that all personnel are safe when using a tool, procedure, work method, or operating technique not recommended by Caterpillar. Ensure that the product will not be damaged or the product made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Personal injury or death can result from machine articulation or movement.Machine frames can move and a person can be crushed.Connect the steering frame lock link between the front and rear frames before working on machine.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury can result from flame cutting or welding on painted areas.The effect of gasses from burned paint is a hazard to the person doing the cutting or welding.Do not flame cut or weld on painted areas.

Personal injury or death can result from fumes, gases and ultraviolet rays from the weld arc.Welding can cause fumes, burn skin and produce ultraviolet rays.Keep your head out of the fumes. Use ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing area. Wear eye, ear and body protection before working.Protect yourself and others; read and understand this warning. Fumes and gases can be dangerous to your health. Ultraviolet rays from the weld arc can injure eyes and burn skin. Electric shock can cause death.Read and understand the manufacturer's instructions and your employer's safety practices. Do not touch live electrical parts.See "American National Standard Z49.1, Safety in Welding and Cutting" published by the American Welding Society.American Welding Society

2501 N.W. 7th Street

Miami, Florida 33125

See "OSHA Safety and Health Standards, 29 CFR 1910", available from U.S. Department of Labor.U.S. Department of Labor

Washington, D.C. 20210

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection,

This Special Instruction covers the procedure to install a wall flow Diesel Particulate Matter (DPM) filter on the above serial numbered Load Haul Dump Machines. This supplemental product support literature should be used with the appropriate Service Manual and the appropriate Parts Manual that is available for this standard machine.Read the entire Special Instruction. Understand the information before you perform any procedures. Understand the information before you order any parts.Safety Section

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive.Ensure that all personnel are safe when using a tool, procedure, work method, or operating technique not recommended by Caterpillar. Ensure that the product will not be damaged or the product made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Personal injury or death can result from machine articulation or movement.Machine frames can move and a person can be crushed.Connect the steering frame lock link between the front and rear frames before working on machine.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury can result from flame cutting or welding on painted areas.The effect of gasses from burned paint is a hazard to the person doing the cutting or welding.Do not flame cut or weld on painted areas.

Personal injury or death can result from fumes, gases and ultraviolet rays from the weld arc.Welding can cause fumes, burn skin and produce ultraviolet rays.Keep your head out of the fumes. Use ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing area. Wear eye, ear and body protection before working.Protect yourself and others; read and understand this warning. Fumes and gases can be dangerous to your health. Ultraviolet rays from the weld arc can injure eyes and burn skin. Electric shock can cause death.Read and understand the manufacturer's instructions and your employer's safety practices. Do not touch live electrical parts.See "American National Standard Z49.1, Safety in Welding and Cutting" published by the American Welding Society.American Welding Society

2501 N.W. 7th Street

Miami, Florida 33125

See "OSHA Safety and Health Standards, 29 CFR 1910", available from U.S. Department of Labor.U.S. Department of Labor

Washington, D.C. 20210

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection,