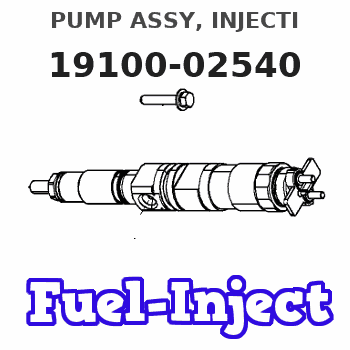

Information pump assy, injecti

Nozzle:

0935003190

Rating:

KIT List:

| Body assy, injecti | No Application |

| Governor assy, mec | 1908900250 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-02540 |

| 002. | BODY ASSY, INJECTI | 09010-06830 |

| 003. | GOVERNOR ASSY, MEC | 09080-04931 |

| 004. | PUMP ASSY, FUEL FE | 09210-01011 |

Scheme ###:

| 000. | [01] | 19100-02540 | PUMP ASSY, INJECTI | 34661-41060 |

| 005. | [01] | 09010-06830 | BODY ASSY, INJECTI | |

| 006. | [01] | 09080-04931 | GOVERNOR ASSY, MEC | 09080-04931 |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | 09001-80081 |

| 008. | [01] | 09001-20260 | NUT, TIMER ROUND | |

| 008. | [01] | 09001-20080 | NUT, TIMER ROUND | 09001-20080 |

| 009. | [01] | 94913-00190 | KEY, WOODRUFF | 94913-00190 |

| 010. | [01] | 94901-50500 | WASHER, SPRING | 94901-50500 |

| 012. | [01] | 09210-01011 | PUMP ASSY, FUEL FE | 34461-00303 |

| 013. | [06] | 94904-70620 | BOLT, W/WASHER | |

| 014. | [01] | 90200-06511 | WASHER, PLATE |

Include in #3:

19100-02540

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-02540 | 34661-4106 | PUMP ASSY, INJECTI | |

| 34661-41060 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Regeneration

The process of particulate collection begins as soon as the engine is started and continues while the engine is operating. At low loads and low exhaust temperatures, PM accumulates in the filter and pressure drop across the filter increases. When exhaust conditions are optimal, the catalyst promotes oxidation between the particulate matter and either oxygen or nitrogen dioxide in the exhaust. This process is called regeneration whereby PM is burned off the substrate walls, resulting in a cleaner filter. The regeneration process is dependent upon exhaust temperature, engine load, exhaust composition, and fuel sulfur content. At a certain exhaust condition, the rate of oxidation eclipses the rate at which PM is being trapped by the filter. The temperature at this exhaust condition is commonly referred to as the regeneration temperature. The exhaust temperature does not have to be above regeneration temperature 100 percent of the time. The more time above regeneration temperature, the cleaner the filter will be. A cleaner filter results in lower backpressure. Operating above the regeneration temperature means that the filter will continuously regenerate and self clean. The requirement to operate the Cat DPF is to run above the regeneration temperature at least 30 percent of the time.REGENERATION IS THE SINGLE MOST IMPORTANT ASPECT OF THE CAT DPF OPERATION. The user must understand and plan for regeneration during the normal duty cycle of the engine. If a filter continues operation without regenerating, the filter will collect more and PM, restricting flow more and consequently adding more backpressure to the engine. If exhaust temperatures increase enough to begin regeneration, the large amount of PM on the filter may create a runaway regeneration. This condition is where the excess PM provides a large amount of fuel to burn. This condition then creates a large exothermic condition in the exhaust. This exothermic condition can be so great that the exothermic condition melts the ceramic substrate. The filter is then said to be burned out or cracked, and is unusable and irreparable. A burned out filter must be replacedOperation in No-Load Mode

A diesel engine should not be operated for long periods of time in a no-load mode. The no-load mode produces large amounts of particulate matter (PM) that can plug the Cat DPF due to low exhaust temperatures. Caterpillar recommends that no more than 12 cold starts, no-load mode of operation be done before running the engine at least 40 percent load

The process of particulate collection begins as soon as the engine is started and continues while the engine is operating. At low loads and low exhaust temperatures, PM accumulates in the filter and pressure drop across the filter increases. When exhaust conditions are optimal, the catalyst promotes oxidation between the particulate matter and either oxygen or nitrogen dioxide in the exhaust. This process is called regeneration whereby PM is burned off the substrate walls, resulting in a cleaner filter. The regeneration process is dependent upon exhaust temperature, engine load, exhaust composition, and fuel sulfur content. At a certain exhaust condition, the rate of oxidation eclipses the rate at which PM is being trapped by the filter. The temperature at this exhaust condition is commonly referred to as the regeneration temperature. The exhaust temperature does not have to be above regeneration temperature 100 percent of the time. The more time above regeneration temperature, the cleaner the filter will be. A cleaner filter results in lower backpressure. Operating above the regeneration temperature means that the filter will continuously regenerate and self clean. The requirement to operate the Cat DPF is to run above the regeneration temperature at least 30 percent of the time.REGENERATION IS THE SINGLE MOST IMPORTANT ASPECT OF THE CAT DPF OPERATION. The user must understand and plan for regeneration during the normal duty cycle of the engine. If a filter continues operation without regenerating, the filter will collect more and PM, restricting flow more and consequently adding more backpressure to the engine. If exhaust temperatures increase enough to begin regeneration, the large amount of PM on the filter may create a runaway regeneration. This condition is where the excess PM provides a large amount of fuel to burn. This condition then creates a large exothermic condition in the exhaust. This exothermic condition can be so great that the exothermic condition melts the ceramic substrate. The filter is then said to be burned out or cracked, and is unusable and irreparable. A burned out filter must be replacedOperation in No-Load Mode

A diesel engine should not be operated for long periods of time in a no-load mode. The no-load mode produces large amounts of particulate matter (PM) that can plug the Cat DPF due to low exhaust temperatures. Caterpillar recommends that no more than 12 cold starts, no-load mode of operation be done before running the engine at least 40 percent load