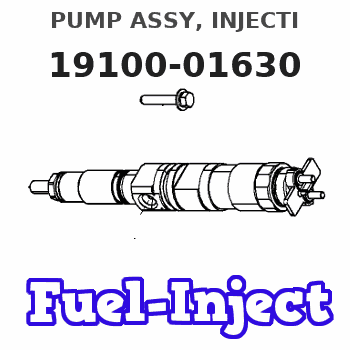

Information pump assy, injecti

Nozzle:

0935002080

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Timer assy, automa | 0918030060 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900190 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-01630 |

| 002. | SWITCH KIT, CONTRO | 09009-90390 |

| 003. | BODY ASSY, INJECTI | 09010-04232 |

| 004. | COVER, BEARING | 09020-10410 |

| 005. | TIMER ASSY, AUTOMA | 09180-01210 |

| 006. | PUMP ASSY, FUEL FE | 09210-00920 |

| 007. | COUPLING ASSY | 09250-00270 |

| 008. | GOVERNOR ASSY, MEC | 19080-00170 |

Scheme ###:

| 000. | [01] | 19100-01630 | PUMP ASSY, INJECTI | 22010-4550 |

| 006. | [01] | 09010-04232 | BODY ASSY, INJECTI | 22110-1590C |

| 007. | [01] | 19080-00170 | GOVERNOR ASSY, MEC | 22310-3490A |

| 008. | [06] | 94904-71150 | BOLT, W/WASHER | 6 306 1001 00 |

| 009. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 011. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 012. | [01] | 09180-01210 | TIMER ASSY, AUTOMA | 22510-1190A |

| 013. | [01] | 09001-20180 | NUT, TIMER ROUND | 22511-1070A |

| 014. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 015. | [01] | 94901-50590 | WASHER, SPRING | 22877-1620A |

| 016. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 017. | [01] | 09006-10011 | COVER, PRIMING PUM | 6 053 1552 60 |

| 018. | [01] | 09250-00270 | COUPLING ASSY | 22610-1080A |

| 020. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 022. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 023. | [03] | 90160-06051 | NUT, HEXAGON | 22825-1480A |

| 024. | [03] | 90258-06001 | WASHER, SPRING | 28219-1110A |

| 025. | [01] | 09009-90390 | SWITCH KIT, CONTRO | 22690-1350A |

Include in #3:

19100-01630

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-01630 | 22010-4550 | PUMP ASSY, INJECTI | |

| 22010-4550 | HINO | PUMP ASSY, INJECTI |

Information:

Introduction

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.