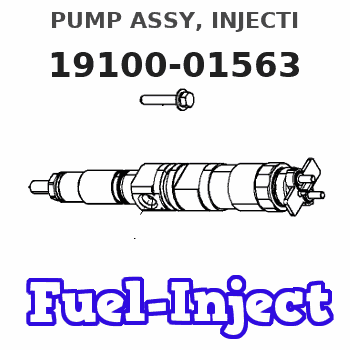

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-01563 |

| 002. | SWITCH KIT, CONTRO | 09009-90450 |

| 003. | BODY ASSY, INJECTI | 09010-05720 |

| 004. | GOVERNOR ASSY, MEC | 09130-01580 |

| 005. | COMPENSATOR SUB-AS | 19260-00100 |

| 006. | TIMER ASSY, AUTOMA | 09180-01820 |

| 007. | PUMP ASSY, FUEL FE | 09210-01750 |

Scheme ###:

| 000. | [01] | 19100-01563 | PUMP ASSY, INJECTI | ME035533 |

| 005. | [01] | 09010-05721 | BODY ASSY, INJECTI | ME702006 |

| 006. | [01] | 09130-01583 | GOVERNOR ASSY, MEC | ME702274 |

| 007. | [01] | 09001-80090 | COVER, CONTROL RAC | ME702251 |

| 008. | [01] | 94914-02840 | O-RING | MH035502 |

| 009. | [01] | 09006-00230 | COVER SUB-ASSY, TI | ME702008 |

| 010. | [01] | 09180-01820 | TIMER ASSY, AUTOMA | ME702009 |

| 011. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 011. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 012. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 013. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 015. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 017. | [01] | 09001-20290 | NUT, TIMER ROUND | ME702547 |

| 018. | [01] | 90801-40280 | O-RING | ME702918 |

| 019. | [01] | 09210-01750 | PUMP ASSY, FUEL FE | ME702019 |

| 020. | [01] | 09009-20100 | BRACKET | ME702036 |

| 021. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 023. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 024. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 025. | [01] | 09009-90450 | SWITCH KIT, CONTRO | ME702011 |

| 026. | [01] | 09028-50021 | CAP | ME035845 |

| 027. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

19100-01563

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-01563 | ME035533 | PUMP ASSY, INJECTI |

Information:

Safety Section

Do not perform any procedure in this Special Instruction until you have read Special Instruction and you understand this information. Use only proper tools and observe all precautions that pertain to the use of those tools. Failure to follow these procedures can result in personal injury. The following procedures should also be observed.Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. The installer must be alert to potential hazards and have the necessary training, skills, and tools needed to perform these functions properly. Wear safety equipment, such as eye protection, foot protection, and other protection as is appropriate to the work site.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. Ensure that any tool, procedure, work method, or operating technique you use that is not recommended by Caterpillar is safe. Ensure that the product will not be damaged or the product will be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Personal injury or death can result from improper assembly procedures.Do not attempt any assembly until you have read and understand the assembly instructions.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Prepare the Machine

If the machine is portable, then move the machine to a smooth, level surface that will support the weight of the machine.

Turn off the machine with the engine switch to the OFF position.

Use proper Lock out and Tag out procedures. Attach a "Do Not Operate" warning tag to the machine start switch or the controls before you perform any service to the machine. These warning tags Special Instruction, SEHS7332 are available from your Caterpillar dealer.Overview

Applicability

The Fluid Property Sensor is offered as an aftermarket attachment for use on all diesel fueled, off-highway engines, both Caterpillar and competitive brands, providing a fleet solution for equipment owners.Choosing the correct Fluid Property Sensor is important. For most applications, the Non-Isolated Sensor will be used. The Isolated Sensor will be used in Marine applications only.Electrical Requirements

This sensor is designed to operate on 12 or 24 volts DC, negative ground. Current draw of the control package is less than 2.0 amps. External solenoids or other loads driven by

Do not perform any procedure in this Special Instruction until you have read Special Instruction and you understand this information. Use only proper tools and observe all precautions that pertain to the use of those tools. Failure to follow these procedures can result in personal injury. The following procedures should also be observed.Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. The installer must be alert to potential hazards and have the necessary training, skills, and tools needed to perform these functions properly. Wear safety equipment, such as eye protection, foot protection, and other protection as is appropriate to the work site.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. Ensure that any tool, procedure, work method, or operating technique you use that is not recommended by Caterpillar is safe. Ensure that the product will not be damaged or the product will be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Personal injury or death can result from improper assembly procedures.Do not attempt any assembly until you have read and understand the assembly instructions.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Prepare the Machine

If the machine is portable, then move the machine to a smooth, level surface that will support the weight of the machine.

Turn off the machine with the engine switch to the OFF position.

Use proper Lock out and Tag out procedures. Attach a "Do Not Operate" warning tag to the machine start switch or the controls before you perform any service to the machine. These warning tags Special Instruction, SEHS7332 are available from your Caterpillar dealer.Overview

Applicability

The Fluid Property Sensor is offered as an aftermarket attachment for use on all diesel fueled, off-highway engines, both Caterpillar and competitive brands, providing a fleet solution for equipment owners.Choosing the correct Fluid Property Sensor is important. For most applications, the Non-Isolated Sensor will be used. The Isolated Sensor will be used in Marine applications only.Electrical Requirements

This sensor is designed to operate on 12 or 24 volts DC, negative ground. Current draw of the control package is less than 2.0 amps. External solenoids or other loads driven by