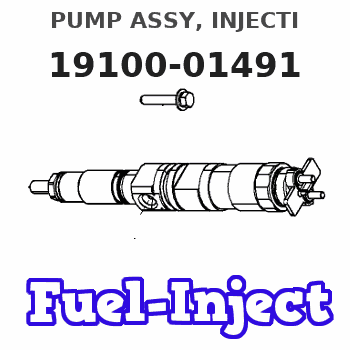

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-01491 |

| 002. | BODY ASSY, INJECTI | 09010-04131 |

| 003. | COVER, BEARING | 09020-10430 |

| 004. | TIMER ASSY, AUTOMA | 09180-02290 |

| 004. | TIMER ASSY, AUTOMA | 09180-02290 |

| 005. | PUMP ASSY, FUEL FE | 09210-00942 |

| 006. | COUPLING ASSY | 09250-00450 |

| 007. | COUPLING ASSY | 09250-00681 |

| 008. | GOVERNOR ASSY, MEC | 19080-00070 |

Scheme ###:

| 000. | [01] | 19100-01491 | PUMP ASSY, INJECTI | 22030-2021 |

| 000. | [01] | 19100-01491 | PUMP ASSY, INJECTI | S2203-02021 |

| 003. | [01] | 09010-04132 | BODY ASSY, INJECTI | 22110-1700A |

| 004. | [01] | 19080-00070 | GOVERNOR ASSY, MEC | 22330-1670A |

| 005. | [02] | 94904-70620 | BOLT, W/WASHER | 22815-1620A |

| 006. | [01] | 09001-80330 | COVER, CONTROL RAC | 22114-1140A |

| 007. | [01] | 09180-02291 | TIMER ASSY, AUTOMA | 22510-2000A |

| 008. | [01] | 09001-20230 | NUT, TIMER ROUND | 22825-1110A |

| 009. | [01] | 90801-40280 | O-RING | 22817-1050A |

| 010. | [01] | 94901-40070 | WASHER, COUNTERSUN | 22877-1580A |

| 011. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 012. | [01] | 09210-00942 | PUMP ASSY, FUEL FE | 22570-1220A |

| 014. | [01] | 94901-81550 | WASHER, COPPER PLA | 96542-2150A |

| 016. | [01] | 09250-00450 | COUPLING ASSY | 22610-1350A |

| 016. | [01] | 09250-00681 | COUPLING ASSY | 22610-1480A |

| 017. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 018. | [01] | 09031-00050 | VALVE ASSY, OVERFL | 22107-1190A |

| 018. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 021. | [02] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 022. | [04] | 91518-06161 | BOLT, W/WASHER | 22815-1310A |

Include in #3:

19100-01491

as PUMP ASSY, INJECTI

19100-01491

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-01491 | 22030-2021 | PUMP ASSY, INJECTI |

Information:

Introduction

There have been some isolated instances of issues with fuel injection pumps on certain 3054C, C3.3, C4.4 (Mech), and C7.1 (Mech) engines. These issues with the fuel injection pump cause the engine to suffer from low power, issues with starting the engine, and excessive smoke.Solution

Ensure that the correct diagnosis procedures have been carried out. Ensure that the following tests have been carried out. Refer to Systems Operation Testing and Adjusting for further information.

Fuel System - Inspect

Air in Fuel - Test

Fuel Injection Nozzle - Test

Fuel Quality - Test

Fuel System - Prime

Fuel System Pressure - TestIf the diagnosis procedures determine that the fuel injection pump has an issue, remove the fuel injection pump from the engine. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove" for the correct procedure. Once the fuel injection pump is removed, follow step1 to step 9 to inspect the fuel injection pump.

Personal injury can result from being struck by parts propelled by a released spring force.Make sure to wear all necessary protective equipment.Follow the recommended procedure and use all recommended tooling to release the spring force.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

If possible, take the fuel injection pump to a clean work area.

Clean the outside surfaces of the fuel injection pump.

Illustration 1 g03117860

Typical example

Place a suitable container under the fuel injection pump to collect any fuel from the fuel injection pump. Use a suitable tool to loosen the drain plug (1). If necessary, retain the fuel collected for analysis if required.

Illustration 2 g03117878

Typical example

Use a suitable pair of pliers to remove the throttle return spring (2).Note: Care should be taken when the spring is removed.

Illustration 3 g03117896

Typical example

Loosen self-locking nut (3). Do not remove the nut.

Illustration 4 g03117916

Typical example

Use a suitable pair of pliers to lift and disconnect throttle spring (4). Remove self-locking nut (3), washer, upper retainer, spring, lower retainer, spacer, lever, and dust cap.Note: Care should be taken when the spring is removed.

Illustration 5 g03117938

Typical example

Remove four screws (6) in the governor cover (7). Gently push the throttle shaft (5) down into the cover (7).

Illustration 6 g03117956

Typical example

To inspect the internal components of the fuel injection pump, gently lift and rotate the cover (7).Note: The cover is still connected internally, if resistance is felt, lo

There have been some isolated instances of issues with fuel injection pumps on certain 3054C, C3.3, C4.4 (Mech), and C7.1 (Mech) engines. These issues with the fuel injection pump cause the engine to suffer from low power, issues with starting the engine, and excessive smoke.Solution

Ensure that the correct diagnosis procedures have been carried out. Ensure that the following tests have been carried out. Refer to Systems Operation Testing and Adjusting for further information.

Fuel System - Inspect

Air in Fuel - Test

Fuel Injection Nozzle - Test

Fuel Quality - Test

Fuel System - Prime

Fuel System Pressure - TestIf the diagnosis procedures determine that the fuel injection pump has an issue, remove the fuel injection pump from the engine. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove" for the correct procedure. Once the fuel injection pump is removed, follow step1 to step 9 to inspect the fuel injection pump.

Personal injury can result from being struck by parts propelled by a released spring force.Make sure to wear all necessary protective equipment.Follow the recommended procedure and use all recommended tooling to release the spring force.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

If possible, take the fuel injection pump to a clean work area.

Clean the outside surfaces of the fuel injection pump.

Illustration 1 g03117860

Typical example

Place a suitable container under the fuel injection pump to collect any fuel from the fuel injection pump. Use a suitable tool to loosen the drain plug (1). If necessary, retain the fuel collected for analysis if required.

Illustration 2 g03117878

Typical example

Use a suitable pair of pliers to remove the throttle return spring (2).Note: Care should be taken when the spring is removed.

Illustration 3 g03117896

Typical example

Loosen self-locking nut (3). Do not remove the nut.

Illustration 4 g03117916

Typical example

Use a suitable pair of pliers to lift and disconnect throttle spring (4). Remove self-locking nut (3), washer, upper retainer, spring, lower retainer, spacer, lever, and dust cap.Note: Care should be taken when the spring is removed.

Illustration 5 g03117938

Typical example

Remove four screws (6) in the governor cover (7). Gently push the throttle shaft (5) down into the cover (7).

Illustration 6 g03117956

Typical example

To inspect the internal components of the fuel injection pump, gently lift and rotate the cover (7).Note: The cover is still connected internally, if resistance is felt, lo