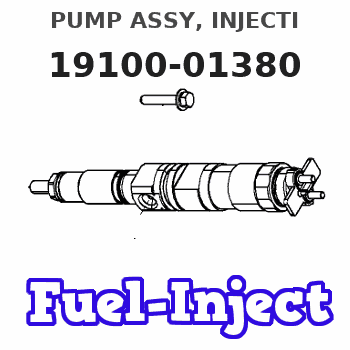

Information pump assy, injecti

Nozzle:

0935002080

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900170 |

Components :

| 001. | PUMP ASSY, INJECTI | 19100-01380 |

| 002. | BODY ASSY, INJECTI | 09010-05820 |

| 003. | COVER, BEARING | 09020-10250 |

| 004. | PUMP ASSY, FUEL FE | 09210-00920 |

| 005. | COUPLING ASSY | 09250-00360 |

| 006. | GOVERNOR ASSY, MEC | 19080-00050 |

Scheme ###:

| 000. | [01] | 19100-01380 | PUMP ASSY, INJECTI | 22030-2010 |

| 006. | [01] | 09010-05820 | BODY ASSY, INJECTI | 22130-1270A |

| 007. | [01] | 19080-00050 | GOVERNOR ASSY, MEC | 22330-1620A |

| 008. | [06] | 91418-06161 | BOLT, W/WASHER | 22815-1380A |

| 009. | [01] | 91518-08221 | BOLT, W/WASHER | 22815-1190A |

| 011. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 012. | [01] | 09250-00360 | COUPLING ASSY | 22630-1020A |

| 013. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 014. | [01] | 09001-20180 | NUT, TIMER ROUND | 22511-1070A |

| 015. | [01] | 94901-50590 | WASHER, SPRING | 22877-1620A |

| 016. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 020. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 022. | [02] | 94901-02480 | WASHER | 22847-1940A |

Include in #3:

19100-01380

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-01380 | 22030-2010 | PUMP ASSY, INJECTI | |

| 22030-2010 | HINO | PUMP ASSY, INJECTI |

Information:

Introduction

The following special instruction outlines the parts and steps needed to update to the new dual tapered roller bearing HEUI pump. The new Hydraulic Electronic Unit Injector (HEUI) pump has physical dimensions that are different than the previous pump. The new HEUI pump may require the addition of new fuel and oil lines along with the pump in most applications. Refer to the parts table and rework instruction for the machine or engine model being updated.Do not perform any procedure that is outlined in this publication without reading this article first.

Table 1

Revision History

Revision Summary of Changes

10 Note added that dowel pin can be removed from fuel pump for installation. Safety Information

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Do not allow dirt to enter the fuel system. Thoroughly clean the area around a fuel system component that will be disconnected. Fit a suitable cover over any disconnected fuel system components.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Do not operate or work on this engine unless you have read and understand the instructions and warnings in the Operation and Maintenance Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Contact any Caterpillar dealer for replacement manuals. Proper care is your responsibility.

Fuel leaked or spilled onto hot surfaces or electrical components can cause a fire. Clean up fuel spills immediately.

Removal Procedure

Refer to the Disassembly and Assembly Manual for the procedure used on the equipment being worked on.Installation Procedure for C9 Industrial Engines

Table 2

Required parts for C9 Industrial Engines (JSC and MBD prefixes only)

Part Numbers Description Quantity

384-0678 Unit Injector Hydraulic Pump Gp 1

227-5904 O-Ring Seal 1

The following special instruction outlines the parts and steps needed to update to the new dual tapered roller bearing HEUI pump. The new Hydraulic Electronic Unit Injector (HEUI) pump has physical dimensions that are different than the previous pump. The new HEUI pump may require the addition of new fuel and oil lines along with the pump in most applications. Refer to the parts table and rework instruction for the machine or engine model being updated.Do not perform any procedure that is outlined in this publication without reading this article first.

Table 1

Revision History

Revision Summary of Changes

10 Note added that dowel pin can be removed from fuel pump for installation. Safety Information

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Do not allow dirt to enter the fuel system. Thoroughly clean the area around a fuel system component that will be disconnected. Fit a suitable cover over any disconnected fuel system components.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Do not operate or work on this engine unless you have read and understand the instructions and warnings in the Operation and Maintenance Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Contact any Caterpillar dealer for replacement manuals. Proper care is your responsibility.

Fuel leaked or spilled onto hot surfaces or electrical components can cause a fire. Clean up fuel spills immediately.

Removal Procedure

Refer to the Disassembly and Assembly Manual for the procedure used on the equipment being worked on.Installation Procedure for C9 Industrial Engines

Table 2

Required parts for C9 Industrial Engines (JSC and MBD prefixes only)

Part Numbers Description Quantity

384-0678 Unit Injector Hydraulic Pump Gp 1

227-5904 O-Ring Seal 1