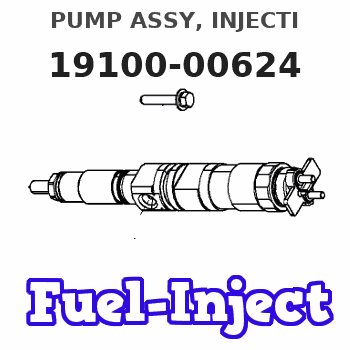

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-00624 |

| 001. | PUMP ASSY, INJECTI | 19100-00624 |

| 002. | SWITCH KIT, CONTRO | 09009-90450 |

| 003. | BODY ASSY, INJECTI | 09010-05700 |

| 004. | BODY ASSY, INJECTI | 09010-09960 |

| 005. | GOVERNOR ASSY, MEC | 09130-01311 |

| 006. | TIMER ASSY, AUTOMA | 09180-01881 |

| 007. | PUMP ASSY, FUEL FE | 09210-01440 |

Scheme ###:

| 000. | [01] | 19100-00623 | PUMP ASSY, INJECTI | ME035522 |

| 000. | [01] | 19100-00624 | PUMP ASSY, INJECTI | ME035522 |

| 005. | [01] | 09010-05701 | BODY ASSY, INJECTI | ME702012 |

| 005. | [01] | 09010-09960 | BODY ASSY, INJECTI | ME736047 |

| 006. | [01] | 09130-01314 | GOVERNOR ASSY, MEC | ME702617 |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | ME702034 |

| 008. | [01] | 94914-02840 | O-RING | MH035502 |

| 009. | [01] | 09006-00230 | COVER SUB-ASSY, TI | ME702008 |

| 010. | [01] | 09180-01881 | TIMER ASSY, AUTOMA | ME702010 |

| 011. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 012. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 013. | [02] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 014. | [01] | 09069-11320 | BRACKET, STOP WIRE | ME703775 |

| 014. | [01] | 09069-10980 | BRACKET, STOP WIRE | ME702548 |

| 015. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 017. | [01] | 09001-20290 | NUT, TIMER ROUND | ME702547 |

| 018. | [01] | 90801-40280 | O-RING | ME702918 |

| 019. | [01] | 09210-01440 | PUMP ASSY, FUEL FE | ME035928 |

| 020. | [01] | 09009-20100 | BRACKET | ME702036 |

| 021. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 023. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 024. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 025. | [01] | 09009-90450 | SWITCH KIT, CONTRO | ME702011 |

| 026. | [01] | 09028-50021 | CAP | ME035845 |

| 027. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

19100-00624

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-00624 | ME035522 | PUMP ASSY, INJECTI |

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Reference Section

Refer to Service Magazine, M0082326, "Diesel Exhaust Fluid (DEF) Contamination on C4.4 Machine Engines".Refer to Service Magazine, M0096547, "Diesel Exhaust Fluid (DEF) Pump Filter Maintenance on Certain C4.4 Machine Engines".Refer to Special Instruction, M0096185, "Diesel Exhaust Fluid (DEF) Pump Diesel Contamination Test on Certain C4.4 Engines".Problem

There have been instances of returned DEF pumps that have no fault found or indicating contamination.Resolution

Complete the form below and attach to any SIMSi claim in addition to a Product Status Report (PSR) from before any troubleshooting was performed or any diagnostic codes were cleared.

Use the electronic service tool to download a PSR with Histograms.

Enter the diagnostic codes that require troubleshooting: ___

Perform the correct troubleshooting procedure for any active diagnostic codes. Refer to Troubleshooting, Diagnostic Trouble Codes.

If the troubleshooting procedure requests that the DEF is tested for contamination or concentration , record the results in Table 1 and Table 2.

For other DEF-related troubleshooting procedures, follow the applicable troubleshooting steps and record the results in Table 3.

Table 1

DEF Contamination

Step Instruction Completed Result Units

1 Perform the test procedure for DEF contamination. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Reference Section

Refer to Service Magazine, M0082326, "Diesel Exhaust Fluid (DEF) Contamination on C4.4 Machine Engines".Refer to Service Magazine, M0096547, "Diesel Exhaust Fluid (DEF) Pump Filter Maintenance on Certain C4.4 Machine Engines".Refer to Special Instruction, M0096185, "Diesel Exhaust Fluid (DEF) Pump Diesel Contamination Test on Certain C4.4 Engines".Problem

There have been instances of returned DEF pumps that have no fault found or indicating contamination.Resolution

Complete the form below and attach to any SIMSi claim in addition to a Product Status Report (PSR) from before any troubleshooting was performed or any diagnostic codes were cleared.

Use the electronic service tool to download a PSR with Histograms.

Enter the diagnostic codes that require troubleshooting: ___

Perform the correct troubleshooting procedure for any active diagnostic codes. Refer to Troubleshooting, Diagnostic Trouble Codes.

If the troubleshooting procedure requests that the DEF is tested for contamination or concentration , record the results in Table 1 and Table 2.

For other DEF-related troubleshooting procedures, follow the applicable troubleshooting steps and record the results in Table 3.

Table 1

DEF Contamination

Step Instruction Completed Result Units

1 Perform the test procedure for DEF contamination. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.