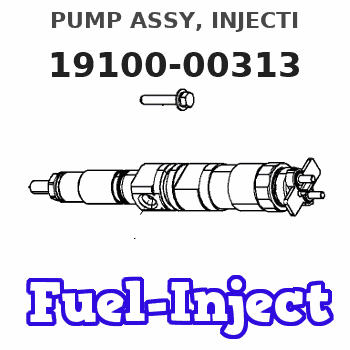

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19100-00313 |

| 002. | BODY ASSY, INJECTI | 09010-05700 |

| 003. | BODY ASSY, INJECTI | 09010-09960 |

| 004. | GOVERNOR ASSY, MEC | 09130-01190 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 006. | PUMP ASSY, FUEL FE | 09210-01440 |

Scheme ###:

| 000. | [01] | 19100-00313 | PUMP ASSY, INJECTI | ME035591 |

| 005. | [01] | 09010-05700 | BODY ASSY, INJECTI | ME702012 |

| 005. | [01] | 09010-09960 | BODY ASSY, INJECTI | ME736047 |

| 006. | [01] | 09130-01190 | GOVERNOR ASSY, MEC | ME702256 |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | ME702034 |

| 008. | [01] | 94914-02840 | O-RING | ME702048 |

| 009. | [01] | 09006-00050 | COVER SUB-ASSY, TI | ME036902 |

| 010. | [01] | 09180-01281 | TIMER ASSY, AUTOMA | ME036901 |

| 011. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 012. | [05] | 90258-10001 | WASHER, SPRING | MC327716 |

| 013. | [04] | 94901-15020 | WASHER, STEEL PLAT | ME702042 |

| 014. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 015. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 016. | [01] | 09001-20220 | NUT, TIMER ROUND | ME702033 |

| 017. | [01] | 09210-01440 | PUMP ASSY, FUEL FE | ME035928 |

| 018. | [01] | 09009-20100 | BRACKET | ME702036 |

| 019. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 020. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 021. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 022. | [01] | 09028-50021 | CAP | ME035845 |

| 023. | [01] | 09009-20140 | BRACKET | ME702037 |

| 024. | [01] | 91266-06201 | NUT, HEXAGON | |

| 025. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

19100-00313

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19100-00313 | ME035591 | PUMP ASSY, INJECTI |

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

If the 312-0092 Nozzle Heater As does not seat properly, follow the procedure that is listed below in order to resolve the problem.Solution

Material will need to be removed from the hex if the 312-0092 Nozzle Heater As is not properly seated. Refer to Illustration 1.

Illustration 1 g01768245

Use a file to remove material on the hex. Refer to Illustration 2. Use clean shop air in order to remove the debris that is generated during the procedure.Note: Do not use any type of chemical cleaner. The chemical cleaner can cause failure of the 312-0092 Nozzle Heater As .

Illustration 2 g01768573

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

If the 312-0092 Nozzle Heater As does not seat properly, follow the procedure that is listed below in order to resolve the problem.Solution

Material will need to be removed from the hex if the 312-0092 Nozzle Heater As is not properly seated. Refer to Illustration 1.

Illustration 1 g01768245

Use a file to remove material on the hex. Refer to Illustration 2. Use clean shop air in order to remove the debris that is generated during the procedure.Note: Do not use any type of chemical cleaner. The chemical cleaner can cause failure of the 312-0092 Nozzle Heater As .

Illustration 2 g01768573