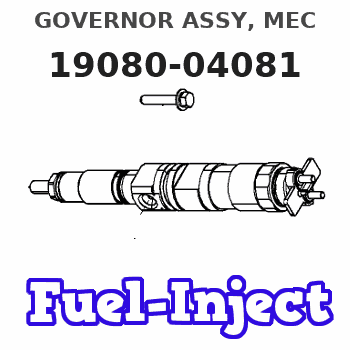

Information governor assy, mec

Rating:

Scheme ###:

| 000. | [01] | 19080-04081 | GOVERNOR ASSY, MEC | |

| 001. | [01] | 09081-00300 | HOUSING SUB-ASSY, | |

| 002. | [01] | 09087-80040 | PLATE | |

| 004. | [01] | 94805-30051 | NUT, HEXAGON, W/HO | |

| 005. | [01] | 09100-60170 | SCREW, STROKE ADJU | |

| 006. | [01] | 94905-03390 | NUT, HEXAGON | |

| 007. | [01] | 09090-10150 | LEVER, TENSION | |

| 008. | [01] | 09091-02050 | ADAPTER ASSY | |

| 008-001. | [01] | 09091-90010 | ADAPTER | |

| 008-002. | [01] | 09091-10010 | SCREW, ADPTER | |

| 008-003. | [01] | 09091-82271 | SPRING, MECHANICAL | |

| 008-004. | [01] | 09089-40010 | E-RING | |

| 008-005. | [1C] | 94901-37880 | WASHER, PLATE, SK | |

| 008-005. | [1C] | 94901-34040 | WASHER, PLATE, SK | |

| 008-005. | [1C] | 94901-34030 | WASHER, PLATE, SK | |

| 008-005. | [1C] | 94901-34020 | WASHER, PLATE, SK | |

| 008-005. | [1C] | 94901-33880 | WASHER, PLATE, SK | |

| 009. | [01] | 09092-30011 | NUT, ADAPTER LOCK | |

| 011. | [01] | 09098-90010 | SHAFT, LEVER SUPPO | |

| 012. | [02] | 09099-10090 | PLUG, SCREW | |

| 013. | [01] | 09093-00700 | LEVER ASSY, CONTRO | |

| 014. | [01] | 90400-02101 | PIN, SPLIT | |

| 016. | [01] | 09104-60010 | SLIDER, SUPPORTING | |

| 017. | [01] | 09056-00170 | CAPSULE, FULL STOP | |

| 018. | [01] | 09103-10030 | NUT, CAP | |

| 019. | [01] | 09101-01220 | COVER SUB-ASSY, GO | |

| 020. | [01] | 09097-00310 | SHACKLE ASSY | |

| 021. | [03] | 90258-06001 | WASHER, SPRING | |

| 022. | [01] | 94913-00050 | KEY, WOODRUFF | |

| 023. | [01] | 09084-00310 | FLYWEIGHT ASSY | |

| 024. | [01] | 94901-50500 | WASHER, SPRING | |

| 025. | [01] | 09084-40010 | NUT, ROUND | |

| 026. | [01] | 09086-10010 | SLEEVE, GOVERNOR | |

| 027. | [4C] | 94901-34060 | WASHER, PLATE, SK | |

| 027. | [4C] | 94901-34070 | WASHER, PLATE, SK | |

| 027. | [4C] | 94901-34080 | WASHER, PLATE, SK | |

| 027. | [4C] | 94901-34090 | WASHER, PLATE, SK | |

| 027. | [4C] | 94901-34100 | WASHER, PLATE, SK | |

| 028. | [01] | 94910-00010 | BEARING, BALL | |

| 029. | [01] | 94904-71190 | BOLT, W/WASHER | |

| 030. | [01] | 09088-00110 | LEVER ASSY, SWIEVE | |

| 031. | [02] | 09089-20080 | BUSHING, LEVER | |

| 032. | [02] | 90801-20160 | O-RING | |

| 033. | [02] | 94907-10090 | WASHER, SNAP | |

| 034. | [01] | 09099-20790 | SPRING, SPEED CONT | |

| 035. | [01] | 09099-30200 | SPRING, START | |

| 036. | [04] | 94904-71760 | BOLT, W/WASHER | |

| 037. | [02] | 94904-72340 | BOLT, W/WASHER | |

| 038. | [01] | 94915-00210 | SEAL, OIL | |

| 039. | [01] | 09107-12870 | LEVER, ADJUSTING | |

| 040. | [01] | 09109-40060 | CAP, LEVER | |

| 041. | [01] | 09109-01330 | LEVER SUB-ASSY, ST | |

| 041. | [01] | 09109-01441 | LEVER SUB-ASSY, ST | |

| 042. | [02] | 91418-06121 | BOLT, W/WASHER | |

| 043. | [01] | 09105-00500 | PLATE SUB-ASSY, CO | |

| 044. | [01] | 09102-40031 | SCREW, ADJUSTING | |

| 045. | [01] | 09092-30060 | NUT, ADAPTER LOCK | |

| 047. | [01] | 94906-21270 | PACKING, RUBBER PL | |

| 048. | [01] | 09103-80040 | SPRING, B | |

| 049. | [01] | 94914-00130 | O-RING | |

| 050. | [01] | 09101-60020 | BUSHING, BEARING | |

| 050. | [01] | 09101-60360 | BUSHING, BEARING | |

| 051. | [01] | 09104-30010 | COVER, SPRING | |

| 052. | [01] | 09103-80050 | SPRING, B | |

| 053. | [01] | 09103-50240 | SHAFT, MECHANICAL | |

| 054. | [01] | 09103-60010 | CUP, SPRING | |

| 055. | [01] | 09103-40130 | LEVER, SUPPORT | |

| 057. | [01] | 09103-30030 | PLATE, CAP | |

| 058. | [01] | 09103-80030 | SPRING, B | |

| 059. | [01] | 94913-00030 | KEY, WOODRUFF | |

| 060. | [01] | 09082-30460 | GASKET | |

| 060. | [01] | 09082-30240 | GASKET | |

| 061. | [01] | 09082-30022 | GASKET | |

| 062. | [01] | 09089-40070 | E-RING | |

| 063. | [01] | 19260-00060 | COMPENSATOR SUB-AS | |

| 064. | [01] | 90801-20260 | O-RING | |

| 065. | [02] | 09024-10010 | WASHER, AIR BLEEDE | |

| 066. | [03] | 90160-06051 | NUT, HEXAGON | |

| 067. | [02] | 94904-72210 | BOLT, W/WASHER | |

| 068. | [01] | 19265-00040 | LEVER SUB-ASSY, FO | |

| 069. | [01] | 19265-30010 | SHAFT, LEVER | |

| 070. | [02] | 90577-05000 | E-RING | |

| 071. | [05] | 94901-33150 | WASHER, PLATE, SK | |

| 072. | [01] | 19265-40010 | SPRING, CANCEL | |

| 073. | [01] | 19264-50010 | SPRING, RETURN, A | |

| 074. | [01] | 19264-60010 | SPRING, RETURN, B | |

| 076. | [01] | 19264-30012 | PISTON | |

| 077. | [01] | 19264-80010 | GASKET | |

| 078. | [01] | 19264-10011 | HOUSING, START EXC | |

| 079. | [01] | 09109-40080 | CAP, LEVER | |

| 081. | [01] | 09024-80010 | WASHER, DRAIN SCRE | |

| 082. | [01] | 19266-00010 | MAGNET ASSY | |

| 088. | [01] | 94919-24580 | COLLAR, STEEL | |

| 089. | [01] | 90107-06201 | BOLT, HEXAGON | |

| 090. | [01] | 09082-10171 | STOPPER | |

| 090. | [01] | 09082-10170 | STOPPER | |

| 091. | [01] | 94905-30140 | NUT, HEXAGON, W/ H | |

| 092. | [01] | 09103-10042 | NUT, CAP | |

| 093. | [02] | 94901-81020 | WASHER, COPPER PLA | |

| 094. | [03] | 91418-06141 | BOLT, W/WASHER | |

| 095. | [02] | 94904-71790 | BOLT, W/WASHER |

Include in #3:

19080-04081

as GOVERNOR ASSY, MEC

Cross reference number

| Part num | Firm num | Firm | Name |

| 19080-04081 | GOVERNOR ASSY, MEC |

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of event code E930 occurring on certain C7.1 engines. Caterpillar is investigating the root cause of these fault codes and to support the investigation, Caterpillar requests that the following procedure is conducted.Solution

Conduct the following steps and ensure that the "TIB Check List" is completed and submitted to the following email address:venters_phil

Download the "Product Status Report" from the engine ECM.

Record the Clean Emissions Module (CEM) serial number from the data plate on the CEM unit.

Conduct the troubleshooting procedure in Troubleshooting, DEF Pressure Is High.

Download the "Product Status Report" from the engine ECM again.

Conduct an Aftertreatment SCR System Dosing – Test. Refer to Systems Operation, Testing and Adjusting, Aftertreatment SCR System Dosing – Test.Note: When removing the Diesel Exhaust Fluid (DEF) injector from the outlet of the Diesel Particulate Filter (DPF), make sure that photographs of any deposits on the injector tip and within the DEF injector port on the Clean Emissions Module (CEM) are taken and documented.

A photograph of the part number and serial number on the side of the DEF injector and mounting must be taken and documented.

Make sure that the measured amount of DEF injected during the test is documented on the "TIB Check List".

If the injector dosing is within 100 mL (3.4 oz) to 130 mL (4.4 oz), reinstall the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

If the injector is not within 100 mL (3.4 oz) to 130 mL (4.4 oz), replace the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

Ensure that the latest flash file is installed in the Engine ECM.

Use the electronic service tool to perform the "Aftertreatment Recovery Procedure".

Conduct an "Aftertreatment System Functional Test". This test is located within the electronic service tool, “Diagnostics" on the main menu, then click "Diagnostic Tests".

If test is successful and no codes are present, return the machine to service.

If test is unsuccessful, contact the Dealer Solutions Network (DSN).

Submit the following items to the email address below:

"TIB Check List"

"Product Status Reports"

DEF injector deposits photographs

CEM deposit photographs

DEF injector part number and serial number photographventers_phil

Table 1

TIB Check List

Step Number Completed (Yes / No) Results / Comments

Step 1. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 2. Record the CEM serial number.

Step 3. "DEF Pressure Is High" troubleshooting.

A. Check the DEF lines for a restriction.

B. Replace the pressure and backflow fittings.

C. Check for a restriction in the DEF pump.

D. Perform an "Aftertreatment System Functional Test".

Step 4. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 5. Aftertreatment SCR System Dosing Test.

A. DEF Injector deposit photograph taken. CEM deposit photograph taken.

Step 6. DEF Injector part number and serial number

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of event code E930 occurring on certain C7.1 engines. Caterpillar is investigating the root cause of these fault codes and to support the investigation, Caterpillar requests that the following procedure is conducted.Solution

Conduct the following steps and ensure that the "TIB Check List" is completed and submitted to the following email address:venters_phil

Download the "Product Status Report" from the engine ECM.

Record the Clean Emissions Module (CEM) serial number from the data plate on the CEM unit.

Conduct the troubleshooting procedure in Troubleshooting, DEF Pressure Is High.

Download the "Product Status Report" from the engine ECM again.

Conduct an Aftertreatment SCR System Dosing – Test. Refer to Systems Operation, Testing and Adjusting, Aftertreatment SCR System Dosing – Test.Note: When removing the Diesel Exhaust Fluid (DEF) injector from the outlet of the Diesel Particulate Filter (DPF), make sure that photographs of any deposits on the injector tip and within the DEF injector port on the Clean Emissions Module (CEM) are taken and documented.

A photograph of the part number and serial number on the side of the DEF injector and mounting must be taken and documented.

Make sure that the measured amount of DEF injected during the test is documented on the "TIB Check List".

If the injector dosing is within 100 mL (3.4 oz) to 130 mL (4.4 oz), reinstall the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

If the injector is not within 100 mL (3.4 oz) to 130 mL (4.4 oz), replace the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

Ensure that the latest flash file is installed in the Engine ECM.

Use the electronic service tool to perform the "Aftertreatment Recovery Procedure".

Conduct an "Aftertreatment System Functional Test". This test is located within the electronic service tool, “Diagnostics" on the main menu, then click "Diagnostic Tests".

If test is successful and no codes are present, return the machine to service.

If test is unsuccessful, contact the Dealer Solutions Network (DSN).

Submit the following items to the email address below:

"TIB Check List"

"Product Status Reports"

DEF injector deposits photographs

CEM deposit photographs

DEF injector part number and serial number photographventers_phil

Table 1

TIB Check List

Step Number Completed (Yes / No) Results / Comments

Step 1. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 2. Record the CEM serial number.

Step 3. "DEF Pressure Is High" troubleshooting.

A. Check the DEF lines for a restriction.

B. Replace the pressure and backflow fittings.

C. Check for a restriction in the DEF pump.

D. Perform an "Aftertreatment System Functional Test".

Step 4. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 5. Aftertreatment SCR System Dosing Test.

A. DEF Injector deposit photograph taken. CEM deposit photograph taken.

Step 6. DEF Injector part number and serial number