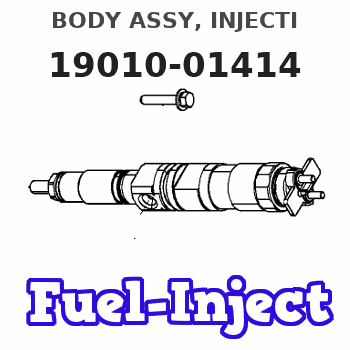

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 19010-01414 | BODY ASSY, INJECTI | 22110-3510A |

| 001. | [01] | 09011-05331 | HOUSING SUB-ASSY, | 22101-4280A |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | S2285-71060-A |

| 002. | [05] | 09013-11091 | HOLDER, DELIVERY V | S2211-61210-A |

| 002. | [05] | 09013-11220 | HOLDER, DELIVERY V | S2211-61230-A |

| 003. | [05] | 09013-61201 | SPRING, DELIVERY V | S2212-51430-A |

| 004. | [05] | 94914-02570 | O-RING | S2281-71260-A |

| 005. | [05] | 09014-02551 | VALVE SUB-ASSY, IN | S2210-32390-A |

| 006. | [05] | 09015-05971 | ELEMENT SUB-ASSY, | S2210-44321-A |

| 007. | [05] | 09016-00150 | SLEEVE SUB-ASSY, C | S2211-81320-A |

| 008. | [01] | 09021-00832 | RACK ASSY, CONTROL | S2211-31930-A |

| 009. | [05] | 09016-30160 | SEAT, SPRING, UPR | S2211-91090-A |

| 010. | [05] | 09016-40250 | SPRING, PUMP PLUNG | 22121-1230A |

| 011. | [05] | 09016-50150 | SEAT, SPRING, LWR | 22122-1100A |

| 012. | [05] | 09017-00320 | TAPPET SUB-ASSY,IN | S2210-51480-A |

| 013. | [ C] | 09043-80471 | SHIM, ELEMENT HOLD | 22885-5590A |

| 013. | [ C] | 09043-80481 | SHIM, ELEMENT HOLD | 22885-5600A |

| 013. | [ C] | 09043-80491 | SHIM, ELEMENT HOLD | S2288-55611-A |

| 013. | [ C] | 09043-80501 | SHIM, ELEMENT HOLD | S2288-55621-A |

| 013. | [ C] | 09043-80901 | SHIM, ELEMENT HOLD | 22885-2410A |

| 013. | [ C] | 09043-80911 | SHIM, ELEMENT HOLD | S2288-52420-A |

| 013. | [ C] | 09043-80461 | SHIM, ELEMENT HOLD | S2288-55580-A |

| 013. | [ C] | 09043-80451 | SHIM, ELEMENT HOLD | S2288-55570-A |

| 013. | [ C] | 09043-80391 | SHIM, ELEMENT HOLD | S2288-52300-A |

| 013. | [ C] | 09043-80401 | SHIM, ELEMENT HOLD | S2288-52310-A |

| 013. | [ C] | 09043-80411 | SHIM, ELEMENT HOLD | S2288-52320-A |

| 013. | [ C] | 09043-80421 | SHIM, ELEMENT HOLD | S2288-52330-A |

| 013. | [ C] | 09043-80431 | SHIM, ELEMENT HOLD | S2288-52340-A |

| 013. | [ C] | 09043-80441 | SHIM, ELEMENT HOLD | S2288-55560-A |

| 014. | [12] | 90196-08651 | NUT, HEXAGON | 22825-1380A |

| 015. | [12] | 94901-35880 | WASHER, PLATE, SK | 22885-2290A |

| 016. | [12] | 90258-08001 | WASHER, SPRING | S2287-71720-A |

| 017. | [01] | 94914-03940 | O-RING | S2281-71470-A |

| 018. | [12] | 09013-90340 | O-RING | S2281-72280-A |

| 019. | [05] | 94901-81730 | WASHER, COPPER PLA | S2284-71550-A |

| 020. | [01] | 09019-11862 | CAMSHAFT, INJECTIO | 22123-2340A |

| 021. | [01] | 94910-10140 | BEARING, ROLLER | S2283-71180-A |

| 022. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | S2212-41090-A |

| 023. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | S2288-56670-A |

| 023. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | S2288-55700-A |

| 023. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | S2288-55690-A |

| 023. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | S2288-55680-A |

| 023. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | S2288-51580-A |

| 023. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | S2288-51570-A |

| 023. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | S2288-51560-A |

| 023. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | S2288-51550-A |

| 025. | [01] | 94915-02820 | SEAL, OIL | S2282-71750-A |

| 026. | [01] | 09020-10430 | COVER, BEARING | S2211-11320-A |

| 027. | [04] | 91518-06161 | BOLT, W/WASHER | S2281-51310-A |

| 028. | [01] | 09043-30020 | RETAINER, BEARING | S2211-11310-A |

| 029. | [01] | 09036-10240 | BEARING, CENTER | S2283-71350-A |

| 030. | [02] | 94900-67300 | SCREW | S2286-51510-A |

| 031. | [02] | 09024-80010 | WASHER, DRAIN SCRE | S2284-71730-A |

| 032. | [01] | 09021-50060 | SCREW, RACK GUIDE | S2281-14850-A |

| 033. | [01] | 09031-70420 | PLUG, SCREW | S2284-51550-A |

| 034. | [01] | 94910-10130 | BEARING, ROLLER | S2283-71050-A |

| 035. | [01] | 09019-30060 | RING, CAMSHAFT ADJ | S2212-41100-A |

| 036. | [04] | 94901-02490 | WASHER | S2287-71100-A |

| 038. | [01] | 94918-00310 | SCREW, HOLLOW | S2283-51310-A |

| 039. | [3C] | 09019-40420 | PLATE, CAMSHAFT SH | S2288-56730-A |

| 039. | [3C] | 09019-40390 | PLATE, CAMSHAFT SH | S2288-56710-A |

| 039. | [3C] | 09019-40380 | PLATE, CAMSHAFT SH | S2288-56700-A |

| 039. | [3C] | 09019-40370 | PLATE, CAMSHAFT SH | S2288-56690-A |

| 039. | [3C] | 09019-40330 | PLATE, CAMSHAFT SH | S2212-91240-A |

| 039. | [3C] | 09019-40320 | PLATE, CAMSHAFT SH | S2212-91230-A |

| 039. | [3C] | 09019-40310 | PLATE, CAMSHAFT SH | S2212-91220-A |

| 039. | [3C] | 09019-40300 | PLATE, CAMSHAFT SH | S2212-91210-A |

| 040. | [01] | 09011-40181 | BUSHING, CONTROL R | S2232-22561-A |

| 041. | [01] | 09036-70040 | BUSHING, CONTROL R | S2213-11190-A |

| 042. | [02] | 94901-02470 | WASHER | S2284-71900-A |

| 044. | [01] | 94918-00060 | SCREW, HOLLOW | S2283-51110-A |

| 045. | [01] | 09011-40110 | BUSHING, CONTROL R | S2213-11200-A |

| 046. | [01] | 94914-00380 | O-RING | S2281-71540-A |

| 048. | [03] | 90160-06051 | NUT, HEXAGON | S2282-51480-A |

| 049. | [03] | 90258-06001 | WASHER, SPRING | S2821-91110-A |

| 053. | [01] | 94901-81040 | WASHER, COPPER PLA | 22843-1430A |

| 054. | [01] | 09011-80470 | NEEDLE, TIMING | S2213-21930-A |

| 055. | [02] | 94904-70620 | BOLT, W/WASHER | S2281-51620-A |

| 056. | [02] | 09020-80320 | PLATE, SHIM | S2288-56740-A |

| 059. | [06] | 09013-30390 | STOPPER, DELIVERY | S2211-71310-A |

| 061. | [01] | 09015-32090 | CYLINDER | S2284-51610-A |

Include in #3:

19010-01414

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19010-01414 | 22110-3510 | BODY ASSY, INJECTI |

Information:

Engine Oil and Filter(s)

Obtain Oil Analysis

To compliment a good preventative maintenance program, Caterpillar recommends using S*O*S analysis at regular intervals to monitor the condition of the engine oil maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are two methods recommended to obtain oil samples from the engine crankcase.

Oil Sampling Valve* Use the sampling valve.* Use a sampling gun inserted into the sump. Refer to How To Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use a drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the beginning or end of the drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase.Oil Change Intervals

Many conditions exist that can affect the selection of an optimum oil change period. The fundamental requirement in this decision must be to maintain the lube oil in an acceptable condition that provides continual engine protection. The quantity and amount of oil available is balanced against the oil's ability to absorb combustion by-products.Due to manufacturing tolerances, engine application and maintenance variations, all engines do not consume fuel and oil at the same rate. The amount of fuel consumed is in direct relation to the maximum oil change interval selected.All oils do not perform equally. Lower quality lube oil requires reduced oil change intervals. Oil analysis provides the best indication of when to change oil.Consult you Caterpillar dealer for complete information and assistance in establishing an S*O*S oil analysis program for your engine.Replace Oil and Filter(s)

Refer to the Model Views for the crankcase drain plug, oil filter, and oil filler locations.Drain Oil

As oil cools, suspended waste particles settle on the bottom of the crankcase or oil pan. The waste particles are not removed with the draining cold oil. Drain the crankcase with the engine stopped and the oil warm. This allows for the draining of waste particles that are suspended in the oil.Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil.1. Remove the crankcase drain plugs. Plugs from both the deep and shallow portions of the oil pan should be removed to allow the oil to drain. An oil sample can be obtained for S*O*S (Scheduled Oil Sampling) analysis at this time.2. Wipe clean and install both crankcase drain plugs.Replace Filter(s)

Change oil filter(s) at every oil change. Make sure to use the correct Caterpillar oil filter(s) for your engine arrangement.

Caterpillar oil filters are built to Caterpillar specifications. Use of an oil filter not recommended by Caterpillar could result in severe damage to your engine

Obtain Oil Analysis

To compliment a good preventative maintenance program, Caterpillar recommends using S*O*S analysis at regular intervals to monitor the condition of the engine oil maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are two methods recommended to obtain oil samples from the engine crankcase.

Oil Sampling Valve* Use the sampling valve.* Use a sampling gun inserted into the sump. Refer to How To Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use a drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the beginning or end of the drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase.Oil Change Intervals

Many conditions exist that can affect the selection of an optimum oil change period. The fundamental requirement in this decision must be to maintain the lube oil in an acceptable condition that provides continual engine protection. The quantity and amount of oil available is balanced against the oil's ability to absorb combustion by-products.Due to manufacturing tolerances, engine application and maintenance variations, all engines do not consume fuel and oil at the same rate. The amount of fuel consumed is in direct relation to the maximum oil change interval selected.All oils do not perform equally. Lower quality lube oil requires reduced oil change intervals. Oil analysis provides the best indication of when to change oil.Consult you Caterpillar dealer for complete information and assistance in establishing an S*O*S oil analysis program for your engine.Replace Oil and Filter(s)

Refer to the Model Views for the crankcase drain plug, oil filter, and oil filler locations.Drain Oil

As oil cools, suspended waste particles settle on the bottom of the crankcase or oil pan. The waste particles are not removed with the draining cold oil. Drain the crankcase with the engine stopped and the oil warm. This allows for the draining of waste particles that are suspended in the oil.Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil.1. Remove the crankcase drain plugs. Plugs from both the deep and shallow portions of the oil pan should be removed to allow the oil to drain. An oil sample can be obtained for S*O*S (Scheduled Oil Sampling) analysis at this time.2. Wipe clean and install both crankcase drain plugs.Replace Filter(s)

Change oil filter(s) at every oil change. Make sure to use the correct Caterpillar oil filter(s) for your engine arrangement.

Caterpillar oil filters are built to Caterpillar specifications. Use of an oil filter not recommended by Caterpillar could result in severe damage to your engine