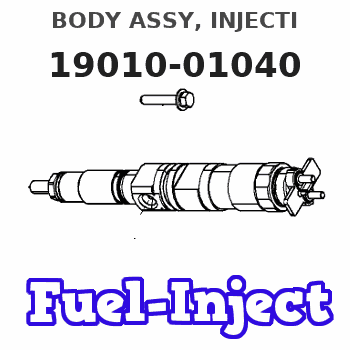

Information body assy, injecti

Rating:

KIT List:

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

| Body assy, injecti | 1904400360 |

Scheme ###:

| 000. | [01] | 19010-01040 | BODY ASSY, INJECTI | |

| 001. | [01] | 19011-05270 | HOUSING KIT, INJEC | |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | |

| 003. | [06] | 09013-00410 | HOLDER SUB-ASSY, D | |

| 005. | [06] | 09013-60930 | SPRING, DELIVERY V | |

| 006. | [06] | 09013-70100 | GASKET, DELIVERY V | |

| 007. | [06] | 09014-02220 | VALVE SUB-ASSY, IN | |

| 008. | [06] | 09015-05850 | ELEMENT SUB-ASSY, | |

| 009. | [06] | 09015-60010 | PINION, PLUNGER CO | |

| 010. | [06] | 09015-70010 | SCREW, PLUNGER CON | |

| 011. | [06] | 09016-10500 | SLEEVE, PLUNGER CO | |

| 012. | [06] | 09016-30191 | SEAT, SPRING, UPR | |

| 013. | [06] | 09016-40090 | SPRING, PUMP PLUNG | |

| 014. | [06] | 09016-50160 | SEAT, SPRING, LWR | |

| 015. | [06] | 09017-00070 | TAPPET SUB-ASSY,IN | |

| 016. | [06] | 09018-90090 | PLUG, INJECTION PU | |

| 017. | [01] | 09019-11780 | CAMSHAFT, INJECTIO | |

| 018. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | |

| 019. | [3C] | 09019-40400 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40290 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | |

| 019. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | |

| 020. | [01] | 09020-10810 | COVER, BEARING | |

| 021. | [01] | 09020-60150 | GASKET, BEARING CO | |

| 022. | [01] | 09021-20180 | RACK, CONTROL | |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | |

| 024. | [06] | 94914-02570 | O-RING | |

| 025. | [03] | 09023-00050 | PLATE SET, VALVE H | |

| 026. | [01] | 94901-80550 | WASHER, COPPER PLA | |

| 027. | [01] | 09031-00480 | VALVE ASSY, OVERFL | |

| 028. | [01] | 09027-00622 | COVER SUB-ASSY, IN | |

| 028-002. | [02] | 09024-30030 | PACKING, AIR BLEED | |

| 028-003. | [02] | 09027-60030 | SCREW | |

| 028-008. | [01] | 09027-50083 | PROCESSING DRAWING | |

| 028-009. | [01] | 09027-20220 | GASKET, INJECTION | |

| 029. | [6C] | 09031-10010 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10290 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10150 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10140 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10130 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10120 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10110 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10100 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10090 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10080 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10020 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10030 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10040 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10050 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10060 | PLATE, TAPPET ADJU | |

| 029. | [6C] | 09031-10070 | PLATE, TAPPET ADJU | |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | |

| 031. | [03] | 90258-06001 | WASHER, SPRING | |

| 032. | [04] | 94904-74750 | BOLT, W/WASHER | |

| 033. | [01] | 94910-10120 | BEARING, ROLLER | |

| 035. | [01] | 94914-00380 | O-RING | |

| 037. | [02] | 90200-05001 | WASHER, PLATE | |

| 038. | [02] | 91418-05081 | BOLT, W/WASHER | |

| 039. | [01] | 09010-80060 | NEEDLE SUB-ASSY, T | |

| 042. | [01] | 94910-10071 | BEARING, ROLLER | |

| 043. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | |

| 044. | [01] | 09036-10150 | BEARING, CENTER | |

| 045. | [02] | 94900-66550 | SCREW | |

| 046. | [02] | 94901-81030 | WASHER, COPPER PLA | |

| 047. | [01] | 94915-01620 | SEAL, OIL | |

| 050. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40170 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40160 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | |

| 050. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH |

Include in #3:

09200-02380

as BODY ASSY, INJECTI

19010-01040

Cross reference number

| Part num | Firm num | Firm | Name |

| 19010-01040 | BODY ASSY, INJECTI |

Information:

Specification

Construction

Governor System Component Parts(1) Sealing metal(2) Sealing wire(3) Low- and high-speed(4) Governor spring(5) Sliding shaft(6) Stopper(7) Governor spring(8) Governor shaft(9) Governor lever(10) Tie-rod(11) Tie-rod clip(12) Tie-rod cover(13) tie-rod cover gasket(14) Tension lever(15) Start spring(16) Governor spring lever(17) Speed control lever assembly(18) Cover assembly(19) Governor cover gasket(20) Return spring(21) Stop lever assembly(22) O-ring(23) Snap ring(24) Stop lever(25) Grooved pin (3 x 20)(26) Grooved pin (3 x 14)(27) Torque spring set(28) Sealing capTORQUE SPRING

Installation of Torque Spring Set

Install and adjust the torque spring set using the following procedure:(1) Set the speed control lever to the high-idling speed position by adjusting the high-speed set bolt.(2) Turn in the torque spring set until engine speed drops about 50 rpm from high-idling speed.(3) From this position, turn back the torque spring set by the specified number of turns (N.) Lock the torque spring set at that position with the special nut.(4) Install the torque spring set sealing cap and stake the cap to prevent loosening. CAUTION There are two types of torque spring set: The single spring type and the double-spring type. Since each torque spring set has been adjusted precisely during assembly, do not tamper with the adjust screw unless it is necessary.

Torque spring setAssembling the Torque Spring Set

When the torque spring set has been disassembled or its component parts have been replaced, reassemble and adjust the torque spring set using the following procedure:

Assembling torque spring setSingle spring type

When installing the single-spring type torque spring set, use the following steps.(1) Lightly turn in adjust screw (5) (with a screw-driver operated by fingertips) until a resistance to screw rotation is felt. Lightly lock the screw at that position with locknut (4).(2) Set the scale to the zero-point. Turn in the spring case (2) until the value of load "A" shown in table below can be attained. Lock the spring case at that position with special nut (3).(3) Temporarily loosen adjust screw (5) until the value of load "A" is reduced by about 200 grams, and then retighten the screw until the value of "B" is attained. Lock the screw at that position with locknut (4).Adjust screw tightening torque: 0.8 to 1.2 kg.(4) To inspect the torque spring set for properly adjusted spring load, use a testing arrangement such as shown in the figure at right. Gradually push the scale against the torque spring set until the stopper (1) is moved (or the pointer of dial gauge deflects). Check that the load applied to the torque spring at that moment coincides with the value of load "C".

Setting of Torque Spring CHECKING

Replace the gear case and inspect the governor. When removing the gear case, be sure to remove the tie-rod cover by the side of the fuel pump and disconnect the tie-rod from the rack.If any parts are found defective, replace them.

Inspecting Torque Spring CAUTION When the governor is assumed to be malfunctioning, check the bearing on the gear case side, too.

Inspection Governor System PartsRemoval and Installation

(Refer to I-06 GEAR CASE AND OIL PUMP.)Removal(1) Removing

Construction

Governor System Component Parts(1) Sealing metal(2) Sealing wire(3) Low- and high-speed(4) Governor spring(5) Sliding shaft(6) Stopper(7) Governor spring(8) Governor shaft(9) Governor lever(10) Tie-rod(11) Tie-rod clip(12) Tie-rod cover(13) tie-rod cover gasket(14) Tension lever(15) Start spring(16) Governor spring lever(17) Speed control lever assembly(18) Cover assembly(19) Governor cover gasket(20) Return spring(21) Stop lever assembly(22) O-ring(23) Snap ring(24) Stop lever(25) Grooved pin (3 x 20)(26) Grooved pin (3 x 14)(27) Torque spring set(28) Sealing capTORQUE SPRING

Installation of Torque Spring Set

Install and adjust the torque spring set using the following procedure:(1) Set the speed control lever to the high-idling speed position by adjusting the high-speed set bolt.(2) Turn in the torque spring set until engine speed drops about 50 rpm from high-idling speed.(3) From this position, turn back the torque spring set by the specified number of turns (N.) Lock the torque spring set at that position with the special nut.(4) Install the torque spring set sealing cap and stake the cap to prevent loosening. CAUTION There are two types of torque spring set: The single spring type and the double-spring type. Since each torque spring set has been adjusted precisely during assembly, do not tamper with the adjust screw unless it is necessary.

Torque spring setAssembling the Torque Spring Set

When the torque spring set has been disassembled or its component parts have been replaced, reassemble and adjust the torque spring set using the following procedure:

Assembling torque spring setSingle spring type

When installing the single-spring type torque spring set, use the following steps.(1) Lightly turn in adjust screw (5) (with a screw-driver operated by fingertips) until a resistance to screw rotation is felt. Lightly lock the screw at that position with locknut (4).(2) Set the scale to the zero-point. Turn in the spring case (2) until the value of load "A" shown in table below can be attained. Lock the spring case at that position with special nut (3).(3) Temporarily loosen adjust screw (5) until the value of load "A" is reduced by about 200 grams, and then retighten the screw until the value of "B" is attained. Lock the screw at that position with locknut (4).Adjust screw tightening torque: 0.8 to 1.2 kg.(4) To inspect the torque spring set for properly adjusted spring load, use a testing arrangement such as shown in the figure at right. Gradually push the scale against the torque spring set until the stopper (1) is moved (or the pointer of dial gauge deflects). Check that the load applied to the torque spring at that moment coincides with the value of load "C".

Setting of Torque Spring CHECKING

Replace the gear case and inspect the governor. When removing the gear case, be sure to remove the tie-rod cover by the side of the fuel pump and disconnect the tie-rod from the rack.If any parts are found defective, replace them.

Inspecting Torque Spring CAUTION When the governor is assumed to be malfunctioning, check the bearing on the gear case side, too.

Inspection Governor System PartsRemoval and Installation

(Refer to I-06 GEAR CASE AND OIL PUMP.)Removal(1) Removing