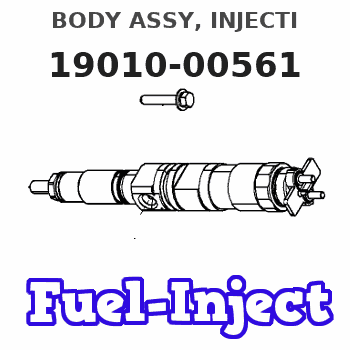

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 19010-00561 | BODY ASSY, INJECTI | 22110-3260 |

| 001. | [01] | 19011-05220 | HOUSING KIT, INJEC | |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 22857-1060A |

| 001-002. | [01] | 09022-10070 | UNION, INJECTION P | 22131-1050A |

| 001-003. | [01] | 09022-10090 | UNION, INJECTION P | |

| 001-003. | [01] | 09022-10040 | UNION, INJECTION P | |

| 003. | [04] | 09013-11101 | HOLDER, DELIVERY V | 22116-1200A |

| 004. | [04] | 09013-30390 | STOPPER, DELIVERY | 22117-1310A |

| 005. | [04] | 09013-61211 | SPRING, DELIVERY V | 22125-1410A |

| 006. | [04] | 09013-70160 | GASKET, DELIVERY V | 22847-2500A |

| 007. | [04] | 09014-02561 | VALVE SUB-ASSY, IN | 22103-2380A |

| 008. | [04] | 09015-05561 | ELEMENT SUB-ASSY, | 22104-3501A |

| 009. | [04] | 09015-60010 | PINION, PLUNGER CO | 22128-1020A |

| 010. | [04] | 09015-70010 | SCREW, PLUNGER CON | 22865-1280A |

| 011. | [04] | 09016-10500 | SLEEVE, PLUNGER CO | 22118-1280A |

| 012. | [04] | 09016-30191 | SEAT, SPRING, UPR | 22119-1190A |

| 013. | [04] | 09016-40350 | SPRING, PUMP PLUNG | 22121-1430A |

| 014. | [04] | 09016-50320 | SEAT, SPRING, LWR | 22122-1170A |

| 015. | [04] | 09017-00350 | TAPPET SUB-ASSY,IN | 22105-1560A |

| 016. | [04] | 09018-90080 | PLUG, INJECTION PU | 22845-1470A |

| 017. | [01] | 09019-11660 | CAMSHAFT, INJECTIO | |

| 018. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | 22124-1160A |

| 019. | [3C] | 09019-40400 | PLATE, CAMSHAFT SH | 22885-6660A |

| 019. | [3C] | 09019-40290 | PLATE, CAMSHAFT SH | 22885-5840A |

| 019. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | 22129-1200A |

| 019. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | 22129-1190A |

| 019. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | 22885-5830A |

| 019. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | 22885-4950A |

| 019. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | 22885-4940A |

| 019. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | 22885-4930A |

| 019. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | 22885-4920A |

| 019. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | 22885-4910A |

| 019. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | 22885-4900A |

| 020. | [01] | 09020-10250 | COVER, BEARING | 22111-1540A |

| 020. | [01] | 09020-10820 | COVER, BEARING | 22111-1810A |

| 021. | [01] | 09020-60200 | GASKET, BEARING CO | 22847-2230A |

| 022. | [01] | 09021-20760 | RACK, CONTROL | 22113-1500A |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | 22811-4850A |

| 024. | [02] | 94901-02490 | WASHER | 22877-1100A |

| 025. | [02] | 09023-00050 | PLATE SET, VALVE H | 22109-1170A |

| 026. | [04] | 94914-02570 | O-RING | 22817-1260A |

| 027. | [02] | 94901-02470 | WASHER | 22847-1900A |

| 028. | [01] | 09027-01460 | COVER SUB-ASSY, IN | |

| 028-001. | [02] | 09024-30030 | PACKING, AIR BLEED | 22847-1890A |

| 028-002. | [01] | 09027-20210 | GASKET, INJECTION | 22847-1990A |

| 028-003. | [01] | 09027-50182 | PROCESSING DRAWING | 22127-1210A |

| 028-004. | [02] | 09027-60030 | SCREW | 22815-1550A |

| 029. | [4C] | 09031-10290 | PLATE, TAPPET ADJU | 22885-2270A |

| 029. | [4C] | 09031-10150 | PLATE, TAPPET ADJU | 22885-1250A |

| 029. | [4C] | 09031-10140 | PLATE, TAPPET ADJU | 22885-1370A |

| 029. | [4C] | 09031-10130 | PLATE, TAPPET ADJU | 22885-1360A |

| 029. | [4C] | 09031-10120 | PLATE, TAPPET ADJU | 22885-1350A |

| 029. | [4C] | 09031-10110 | PLATE, TAPPET ADJU | 22885-1240A |

| 029. | [4C] | 09031-10100 | PLATE, TAPPET ADJU | 22885-1230A |

| 029. | [4C] | 09031-10090 | PLATE, TAPPET ADJU | 22885-1340A |

| 029. | [4C] | 09031-10080 | PLATE, TAPPET ADJU | 22885-1330A |

| 029. | [4C] | 09031-10010 | PLATE, TAPPET ADJU | 22885-1130A |

| 029. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | 22885-1140A |

| 029. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | 22885-1150A |

| 029. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | 22885-1160A |

| 029. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | 22885-1170A |

| 029. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | 22885-1180A |

| 029. | [4C] | 09031-10070 | PLATE, TAPPET ADJU | 22885-1190A |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | 22825-1480A |

| 031. | [03] | 90258-06001 | WASHER, SPRING | 28219-1110A |

| 032. | [04] | 94904-71360 | BOLT, W/WASHER | 22815-2500A |

| 033. | [01] | 94910-10120 | BEARING, ROLLER | 22837-1230A |

| 034. | [01] | 94915-01620 | SEAL, OIL | 22827-1040A |

| 035. | [01] | 94914-00380 | O-RING | 22817-1540A |

| 036. | [01] | 94918-00060 | SCREW, HOLLOW | 22835-1110A |

| 037. | [01] | 94918-00310 | SCREW, HOLLOW | 22835-1310A |

| 044. | [01] | 94910-10071 | BEARING, ROLLER | 22837-1100A |

| 045. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | 22124-1090A |

| 046. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | 22885-6670A |

| 046. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | 22885-5700A |

| 046. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | 22885-5690A |

| 046. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | 22885-5680A |

| 046. | [3C] | 09019-40170 | PLATE, CAMSHAFT SH | 22129-1180A |

| 046. | [3C] | 09019-40160 | PLATE, CAMSHAFT SH | 22129-1170A |

| 046. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | 22885-1580A |

| 046. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | 22885-1570A |

| 046. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | 22885-1560A |

| 046. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | 22885-1550A |

| 047. | [01] | 09011-80560 | NEEDLE, TIMING | 22132-1720A |

| 048. | [02] | 91418-06121 | BOLT, W/WASHER | 22815-1500A |

| 049. | [01] | 09020-80290 | PLATE, SHIM | 22885-5860A |

| 051. | [01] | 09069-00700 | BRACKET SUB-ASSY, | |

| 052. | [01] | 91418-08161 | BOLT, W/WASHER | |

| 053. | [01] | 09045-30120 | STAY, INJECTION PU | 11409-1130B |

| 054. | [02] | 91418-08351 | BOLT, W/WASHER | 9161B-60835 |

Include in #3:

09200-01084

as BODY ASSY, INJECTI

19010-00561

Cross reference number

| Part num | Firm num | Firm | Name |

| 19010-00561 | 22110-3260 | BODY ASSY, INJECTI |

Information:

F14. Remove the big end caps, bearing shells and bolts (Fig. F.1). If the bearing shells removed are serviceable, refit them in their original positions.

F25. Push pistons and connecting rods out of the top of the cylinders (Fig. F.2). Keep each piston and connecting rod assembly separate, each to each as markedTo Remove Pistons and Rings from Connecting Rods

1. Remove the rings from each piston.2. Remove the circlips and withdraw the gudgeon pin. If the gudgeon pin is tight in the piston bore, warm the piston in clean liquid to a temperature of 100/120°F (38/49°C).Inspection

1. Examine the pistons for scoring and clean carbon from the ring grooves. Check the clearance of the new piston rings in their respective grooves and if, with a new ring fitted the vertical groove clearance exceeds 0.008 in (0,20 mm) fit new piston.2. Check the fitted gap of the rings in the unworn portion at top of cylinder bore. For details of ring gap dimensions see "Technical Data", Pages B.6 to B.7. Ring gaps for conformable rings are with spring fitted.3. Check the fit of the gudgeon pin in the piston bore and in the small end bush. For details of piston bore, gudgeon pin and small end bush bore diameters see "Technical Data", Page B.7. When renewing a small end bush, ensure that the oil hole in the bush aligns with the hole in the connecting rod. Ream out to suit the gudgeon pin and check the connecting rod for parallelism see "Technical Data", Page B.8. The small end of the connecting rod on T4.236 engines is wedge shaped and the small end bush should be machined to suit the contours of the wedge. The earlier T4.236 connecting rod is also drilled from the big end to the small end to provide piston cooling by a feed of lubricating oil. Later T4.236 engines have piston cooling jets fitted in the cylinder block wall.4. Examine the big end bearings for wear and scoring. Also examine the crankpins for wear and ovality. For crankshaft details see page B.8.

F3To Assemble the Pistons to the Connecting Rods

If the original pistons are being used they must be assembled to the original connecting rods. For markings of pistons and connecting rods see Figs. F.8 and F.9.1. The cavity in the piston crown is off-set towards one side of the piston. Place the piston on the connecting rod with the cavity towards the side of the rod which carries the rod and cap identification numbers. Insert the gudgeon pin and fit new circlips, warming the piston, if necessary.2. Fit the rings in the following order, ensuring that the ring gaps are equally spaced around the piston.(a) 4.2482 Engines (see Fig. F.4)

F4Chrome Faced Spring Loaded Conformable Scraper - above gudgeon pin.Internally Stepped Taper Faced Compression - second groove.Molybdenum Faced Internally Stepped Barrel Faced Compression - top groove.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically