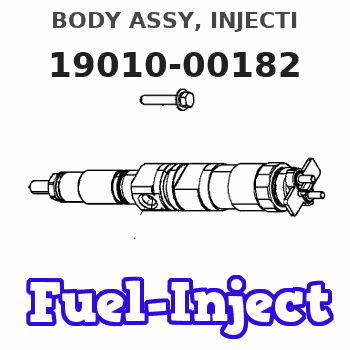

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 19010-00182 | BODY ASSY, INJECTI | |

| 001. | [01] | 09011-04431 | HOUSING SUB-ASSY, | |

| 001. | [01] | 09011-05730 | HOUSING SUB-ASSY, | |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 85265-00057 |

| 002. | [06] | 09013-00540 | HOLDER SUB-ASSY, D | |

| 002. | [06] | 09013-00311 | HOLDER SUB-ASSY, D | |

| 003. | [06] | 09013-60910 | SPRING, DELIVERY V | |

| 004. | [06] | 94914-02570 | O-RING | 94914-02570 |

| 005. | [06] | 09014-01960 | VALVE SUB-ASSY, IN | 33A6500213 |

| 006. | [06] | 09015-05354 | ELEMENT SUB-ASSY, | |

| 006. | [06] | 09015-06460 | ELEMENT SUB-ASSY, | |

| 007. | [06] | 09016-00150 | SLEEVE SUB-ASSY, C | 09016-00150 |

| 008. | [01] | 09021-20700 | RACK, CONTROL | |

| 009. | [06] | 09016-30160 | SEAT, SPRING, UPR | 09016-30160 |

| 010. | [06] | 09016-40250 | SPRING, PUMP PLUNG | |

| 011. | [06] | 09016-50150 | SEAT, SPRING, LWR | |

| 012. | [06] | 09017-00320 | TAPPET SUB-ASSY,IN | |

| 013. | [ C] | 09043-80861 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80871 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80881 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80891 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80901 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80911 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80631 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80621 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80441 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80431 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80421 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80411 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80401 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80391 | SHIM, ELEMENT HOLD | |

| 014. | [12] | 90196-08651 | NUT, HEXAGON | |

| 015. | [12] | 94901-35880 | WASHER, PLATE, SK | |

| 016. | [12] | 90258-08001 | WASHER, SPRING | CSA915D100 |

| 017. | [01] | 09020-60070 | GASKET, BEARING CO | |

| 017. | [01] | 09020-60240 | GASKET, BEARING CO | |

| 018. | [18] | 09013-90020 | O-RING | |

| 018. | [12] | 09013-90340 | O-RING | |

| 019. | [06] | 94901-81730 | WASHER, COPPER PLA | |

| 020. | [01] | 09019-11560 | CAMSHAFT, INJECTIO | |

| 021. | [01] | 94910-10140 | BEARING, ROLLER | |

| 022. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | |

| 023. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | 09019-40070 |

| 023. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | |

| 023. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | |

| 023. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | |

| 023. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | |

| 023. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | 09019-40100 |

| 023. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | 09019-40090 |

| 023. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | 09019-40080 |

| 025. | [01] | 94915-01420 | SEAL, OIL | |

| 025. | [01] | 94915-02820 | SEAL, OIL | |

| 026. | [01] | 09020-10501 | COVER, BEARING | |

| 027. | [04] | 91418-06201 | BOLT, W/WASHER | 91418-06201 |

| 028. | [01] | 09043-30020 | RETAINER, BEARING | |

| 029. | [01] | 09036-10180 | BEARING, CENTER | 09036-10180 |

| 029. | [01] | 09036-10240 | BEARING, CENTER | |

| 030. | [02] | 90015-06181 | SCREW, SLOTTED OVA | |

| 030. | [02] | 94900-66510 | SCREW | |

| 030. | [02] | 94900-67300 | SCREW | |

| 031. | [04] | 09024-80010 | WASHER, DRAIN SCRE | 09024-80010 |

| 032. | [01] | 09021-50060 | SCREW, RACK GUIDE | 09021-50060 |

| 033. | [01] | 09031-70140 | PLUG, SCREW | |

| 034. | [01] | 94910-10130 | BEARING, ROLLER | |

| 035. | [01] | 09019-30060 | RING, CAMSHAFT ADJ | |

| 036. | [04] | 09022-20070 | WASHER, FUEL PIPE | 85265-00079 |

| 038. | [01] | 09024-50390 | SCREW, HOLLOW | |

| 039. | [3C] | 09019-40420 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40390 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40380 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40370 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40330 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40320 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40310 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40300 | PLATE, CAMSHAFT SH | |

| 040. | [02] | 09011-40110 | BUSHING, CONTROL R | |

| 041. | [01] | 09036-70040 | BUSHING, CONTROL R | |

| 046. | [01] | 94914-00380 | O-RING | 85265-00084 |

| 047. | [03] | 90258-06001 | WASHER, SPRING | 90258-06001 |

| 048. | [03] | 90160-06051 | NUT, HEXAGON | 85265-00085 |

| 049. | [02] | 09024-40160 | SCREW, AIR BLEEDER | |

| 055. | [01] | 09031-00210 | VALVE ASSY, OVERFL | |

| 059. | [01] | 94901-80350 | WASHER, COPPER PLA | 94901-80350 |

Include in #3:

19010-00182

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19010-00182 | BODY ASSY, INJECTI |

Information:

The following charts give general torques for bolts, nuts and taperlock studs of SAE Grade 5 or better quality.

Torques for Bolts and Nuts With Standard Threads

Torques for Taperlock Studs

Use these standard torque values for all fasteners unless otherwise specified in this publication or in the Service Manual.Torque for Metric Fasteners

This product uses 10.9 Grade metric fasteners.

Be very careful never to mix metric with customary (standard) fasteners. Mismatched or incorrect fasteners will cause engine damage or malfunction and may even result in personal injury.Original fasteners removed from the engine should be saved for reassembly whenever possible. If new fasteners are needed, they must be of the same size and grade as the ones that are being replaced.The material strength identification is usually shown on the bolt head by numbers (8.8, 10.9, etc.). Use these standard torque values unless otherwise specified in this publication or the Service Manual.The following charts give general torques for bolts and nuts with Metric Threads of SAE Grade 8.8 or better quality.

Torques for Bolts and Nuts with Metric Threads

Torque for Standard Hose Clamps-Worm Drive Band Type

The following chart gives the torques for initial installation of hose clamps on new hose and for reassembly or tightening of hose clamps on existing hose.

Torque for Constant Torque Hose Clamps

A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp. Due to extreme temperature changes, hose will heat set. Heat setting causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new, constant torque hose clamp will help prevent these failures.Each installation application can be different depending on the type of hose, fitting material and anticipated expansion or contraction of the hose and fittings. A torque wrench should be used for proper installation of the new, constant torque hose clamps. Constant torque hose clamps should be installed as follows:* To allow for maximum expansion, install clamps at 50 lb in (5.7 N m).* To allow for equal expansion and contraction, install clamps at 90 lb in (10.2 N m).* To allow for maximum contraction, install clamps at 125 lb in (14.1