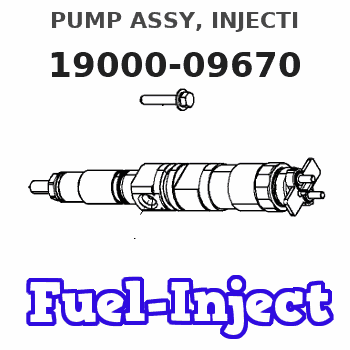

Information pump assy, injecti

Nozzle:

0935002200

Rating:

KIT List:

| Body assy, injecti | 1904400430 |

| Governor assy, mec | 1908900240 |

| Timer assy, automa | 0918030010 |

| Pump assy, fuel fe | 1922900070 |

| Pump assy, fuel fe | 1922900070 |

Components :

| 001. | PUMP ASSY, INJECTI | 19000-09670 |

| 002. | SWITCH KIT, CONTRO | 09009-90280 |

| 003. | BODY ASSY, INJECTI | 09010-05920 |

| 004. | COVER, BEARING | 09020-10110 |

| 005. | GOVERNOR ASSY, MEC | 09130-00803 |

| 005. | GOVERNOR ASSY, MEC | 09130-00803 |

| 005. | GOVERNOR ASSY, MEC | 09130-00803 |

| 006. | TIMER ASSY, AUTOMA | 09180-01571 |

| 007. | PUMP ASSY, FUEL FE | 09210-00950 |

| 008. | PUMP ASSY, FUEL FE | 09210-01900 |

| 009. | COUPLING ASSY | 09250-00420 |

| 010. | COUPLING ASSY | 09250-00631 |

Scheme ###:

| 000. | [01] | 19000-09670 | PUMP ASSY, INJECTI | 22010-4010 |

| 001. | [01] | 09010-05920 | BODY ASSY, INJECTI | 22110-2060A |

| 002. | [01] | 09130-00803 | GOVERNOR ASSY, MEC | 22310-2332A |

| 003. | [01] | 09180-01571 | TIMER ASSY, AUTOMA | 22510-1510A |

| 004. | [01] | 09210-01900 | PUMP ASSY, FUEL FE | 22570-1330A |

| 004. | [01] | 09210-00950 | PUMP ASSY, FUEL FE | 22570-1260A |

| 005. | [01] | 09250-00420 | COUPLING ASSY | 22610-1320A |

| 005. | [01] | 09250-00631 | COUPLING ASSY | 22610-1471A |

| 006. | [01] | 09009-90280 | SWITCH KIT, CONTRO | 22690-1170A |

| 012. | [08] | 91518-06161 | BOLT, W/WASHER | 22815-1310A |

| 013. | [01] | 09001-20230 | NUT, TIMER ROUND | 22825-1110A |

| 014. | [01] | 94901-40070 | WASHER, COUNTERSUN | 22877-1190A |

| 015. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 016. | [01] | 09045-90030 | PIN | 22358-1010A |

| 017. | [01] | 90801-40280 | O-RING | 22817-1050A |

| 018. | [01] | 09002-60091 | SCREW, ADJUSTING | 22396-1250A |

| 019. | [01] | 09003-20150 | CAP | 22114-1260A |

| 020. | [01] | 09036-70050 | BUSHING, CONTROL R | 22372-1120A |

| 021. | [01] | 94905-03071 | NUT, HEXAGON | 22825-1920A |

| 022. | [01] | 94901-81240 | WASHER, COPPER PLA | 22847-1690A |

Include in #3:

19000-09670

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-09670 | 22010-4010 | PUMP ASSY, INJECTI | |

| 22010-4010 | HINO | PUMP ASSY, INJECTI |

Information:

All valves in fuel return line must be open before and during engine operation to prevent high fuel pressure. High fuel pressure may cause filter housing failure or other damage.Each time any significant quantity of oil (or other fluid) is spilled on or near the engine it should be cleaned up. Accumulated grease and oil on an engine is a fire hazard. Remove this debris with steam cleaning or high pressure water.Wipe clean all fittings, caps and plugs before servicing.

Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well-ventilated area and, if in an enclosed area, vent the exhaust to the outside.

Do not start the engine or move any of the controls if there is a DO NOT OPERATE or similar warning tag attached to the start switch or controls.The operator must be satisfied that no one will be endangered before starting the engine.If the engine has not been run for several weeks, fuel may have drained and allowed air into the filter housing. Also, when fuel filters have been changed, some air space will be left in the housing. In these instances, prime the fuel system.Refer to Priming the Fuel System in this publication for more information.For starting below -18°C (0°F), use of optional cold weather starting aids are recommended. A cylinder block coolant heater or extra battery capacity may be required.For temperatures below -23°C (-10°F) consult your Caterpillar dealer.Electric Starting

Startability will be improved at temperatures below 16°C (60°F) by the use of a starting aid. A jacket water (coolant) heater or other means can be used to heat the crankcase oil.Start the engine using the following procedure:1. Perform all before-starting inspections.2. If the engine is equipped with a manual control, ensure that is in the RUN position. Place the transmission in NEUTRAL (and disengage the flywheel clutch, if equipped). For Generator Sets, open the main electrical circuit breaker.2. Move throttle to approximately half engine speed to get the fuel rack to move to the FUEL ON position.3. Turn the starter switch to START (or battery disconnect switch to the ON position) or the Engine Control Switch (ECS) to MAN. START. The starting motor will crank and attempt to start the engine. At temperatures below 0°C (32°F), it may be necessary to spray starting fluid into the air cleaner inlet. Additional injections of ether may be required to start and/or achieve low idle speed.

Excessive ether can cause piston and ring damage. When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Failure to do so could result in an explosion and/or fire and possible personal injury.Use ether for cold starting purposes only.

Do not crank the engine for more than 30 seconds.

If a warm engine fails to start within 30 seconds: release the starter switch and wait two minutes to allow the starter motor to cool before using it again.4. As soon as the engine