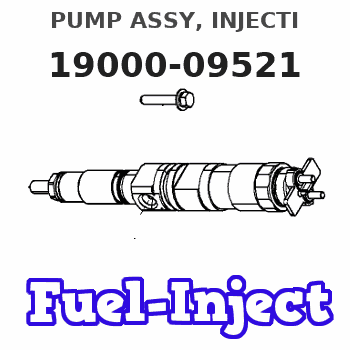

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-09521 |

| 002. | BODY ASSY, INJECTI | 09010-06011 |

| 003. | GOVERNOR ASSY, MEC | 09130-01000 |

| 004. | GOVERNOR ASSY, MEC | 09130-02610 |

| 005. | PUMP ASSY, FUEL FE | 09210-00971 |

Scheme ###:

| 000. | [01] | 19000-09521 | PUMP ASSY, INJECTI | 22100-68140 |

| 001. | [01] | 09010-06011 | BODY ASSY, INJECTI | 22120-68130 |

| 002. | [01] | 09130-01000 | GOVERNOR ASSY, MEC | 22410-68110 |

| 002. | [01] | 09130-02610 | GOVERNOR ASSY, MEC | |

| 003. | [01] | 09210-00971 | PUMP ASSY, FUEL FE | 22510-77130 |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | |

| 008. | [01] | 94913-00190 | KEY, WOODRUFF | 90099-13020 |

| 009. | [01] | 09001-20260 | NUT, TIMER ROUND | 22611-68010 |

| 010. | [02] | 91418-06201 | BOLT, W/WASHER | 90091-20608 |

| 011. | [04] | 94904-72690 | BOLT, W/WASHER | 90099-04319 |

| 017. | [01] | 94904-04300 | BOLT, HEXAGON | 90031-01132 |

| 017. | [01] | 94904-73910 | BOLT, W/WASHER | 90099-04346 |

| 018. | [01] | 90258-08001 | WASHER, SPRING | 94511-00800 |

| 019. | [01] | 09028-50050 | CAP |

Include in #3:

19000-09521

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-09521 | 22100-6814 | PUMP ASSY, INJECTI |

Information:

Fuel Injection Nozzles

Exchange

Whenever the engine performs in such a manner that a fuel injection nozzle is suspected of causing irregular running, smoking or knocking, isolate each fuel injection nozzle, one at a time, to determine the malfunctioning nozzle. For complete fuel injection nozzle information, consult your authorized Caterpillar dealer.1. Start the engine. 2. Loosen the fuel injection line nut at the cylinder head, one at a time, with the engine running.3. When a cylinder is found where the loosened fuel line nut does not make a difference in engine performance or smoking, have that cylinder injection nozzle exchanged.Be sure to tighten each fuel line nut after the test, before the next fuel line nut is loosened. Tighten fuel line nuts to a torque of 40 7 N m (30 5 lb ft). Do not over torque the fuel injection line nut since this could cause permanent damage to the ends of the fuel injection line. Damaged fuel injection lines cannot be reused.4. Stop the engine.Maintenance Options

Dealer Test - Your Caterpillar dealer can test your nozzles for valve opening pressure, internal return leakage and external leakage, etc. Refer to Special Instruction, form SEHS7292, for information regarding fuel nozzle test procedures and tools required. Remanufactured - This process uses manufacturing techniques and procedures to restore fuel injection nozzles to "like-new" performance capability. This process always involves an end product which conforms to the manufacturer's original functional specification.Your Caterpillar Remanufactured nozzles have been tested for valve opening pressure, steady flow, internal return leakage, external leakage and an orifice inspection. New - Replace with new fuel injection nozzles.Before deciding which method is best, you should make sure you have considered all of the options and costs associated with repair. Some considerations are: * Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured component cost.* Remanufactured components from Caterpillar are covered by a national factory warranty.Caterpillar Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends the following: * Dealer Testing, if maintenance is being performed at an approved Caterpillar servicing facility.* Remanufactured components, when a nozzle test tool is not readily available. For complete fuel injection nozzle testing and cleaning, consult your authorized Caterpillar engine dealer.To Remove and Install Injection Nozzles

Refer to the Service Manual for your engine to remove and install fuel injection nozzles.Air Compressor

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain the air compressor before it fails will be less costly to you than repairing the air compressor after failure.If you operate the engine until the air compressor fails, you could cause additional damage to your engine. For example: A failed air compressor could contaminate the engine oil with foreign material since engine oil also lubricates the air compressor. The circulation of these contaminants through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your

Exchange

Whenever the engine performs in such a manner that a fuel injection nozzle is suspected of causing irregular running, smoking or knocking, isolate each fuel injection nozzle, one at a time, to determine the malfunctioning nozzle. For complete fuel injection nozzle information, consult your authorized Caterpillar dealer.1. Start the engine. 2. Loosen the fuel injection line nut at the cylinder head, one at a time, with the engine running.3. When a cylinder is found where the loosened fuel line nut does not make a difference in engine performance or smoking, have that cylinder injection nozzle exchanged.Be sure to tighten each fuel line nut after the test, before the next fuel line nut is loosened. Tighten fuel line nuts to a torque of 40 7 N m (30 5 lb ft). Do not over torque the fuel injection line nut since this could cause permanent damage to the ends of the fuel injection line. Damaged fuel injection lines cannot be reused.4. Stop the engine.Maintenance Options

Dealer Test - Your Caterpillar dealer can test your nozzles for valve opening pressure, internal return leakage and external leakage, etc. Refer to Special Instruction, form SEHS7292, for information regarding fuel nozzle test procedures and tools required. Remanufactured - This process uses manufacturing techniques and procedures to restore fuel injection nozzles to "like-new" performance capability. This process always involves an end product which conforms to the manufacturer's original functional specification.Your Caterpillar Remanufactured nozzles have been tested for valve opening pressure, steady flow, internal return leakage, external leakage and an orifice inspection. New - Replace with new fuel injection nozzles.Before deciding which method is best, you should make sure you have considered all of the options and costs associated with repair. Some considerations are: * Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured component cost.* Remanufactured components from Caterpillar are covered by a national factory warranty.Caterpillar Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends the following: * Dealer Testing, if maintenance is being performed at an approved Caterpillar servicing facility.* Remanufactured components, when a nozzle test tool is not readily available. For complete fuel injection nozzle testing and cleaning, consult your authorized Caterpillar engine dealer.To Remove and Install Injection Nozzles

Refer to the Service Manual for your engine to remove and install fuel injection nozzles.Air Compressor

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain the air compressor before it fails will be less costly to you than repairing the air compressor after failure.If you operate the engine until the air compressor fails, you could cause additional damage to your engine. For example: A failed air compressor could contaminate the engine oil with foreign material since engine oil also lubricates the air compressor. The circulation of these contaminants through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your