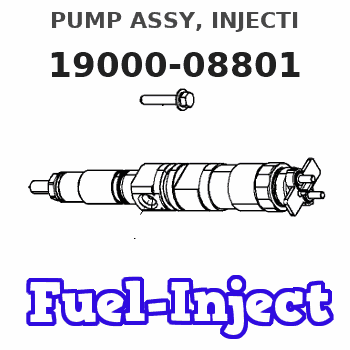

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-08801 |

| 002. | BODY ASSY, INJECTI | 09010-05870 |

| 003. | GOVERNOR ASSY, MEC | 09080-09030 |

| 004. | TIMER ASSY, AUTOMA | 09180-01930 |

| 005. | PUMP ASSY, FUEL FE | 09210-00920 |

| 006. | PUMP ASSY, FUEL FE | 09210-02120 |

| 007. | COUPLING ASSY | 09250-00410 |

Scheme ###:

| 000. | [01] | 19000-08801 | PUMP ASSY, INJECTI | 22030-1801 |

| 006. | [01] | 09010-05870 | BODY ASSY, INJECTI | 22130-1240A |

| 007. | [01] | 09080-09030 | GOVERNOR ASSY, MEC | 22330-1560A |

| 008. | [06] | 91418-06161 | BOLT, W/WASHER | 22815-1380A |

| 009. | [01] | 91518-08221 | BOLT, W/WASHER | 22815-1190A |

| 011. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 011. | [01] | 09210-02120 | PUMP ASSY, FUEL FE | |

| 011. | [01] | 09210-00920 | PUMP ASSY, FUEL FE | 22570-1250A |

| 012. | [01] | 09250-00410 | COUPLING ASSY | 22610-1300A |

| 013. | [01] | 09001-80120 | COVER, CONTROL RAC | 22371-1170A |

| 014. | [01] | 09001-20180 | NUT, TIMER ROUND | 22511-1070A |

| 015. | [01] | 94901-50590 | WASHER, SPRING | 22877-1620A |

| 016. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 017. | [01] | 09180-01930 | TIMER ASSY, AUTOMA | 22510-1850A |

| 020. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 022. | [02] | 94901-02480 | WASHER | 22847-1940A |

Include in #3:

19000-08801

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-08801 | 22030-1801 | PUMP ASSY, INJECTI |

Information:

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

Inspect Engine Before Starting

A walk-around inspection is recommended to ensure the installation is clean and leaks are kept to a minimum. This should only take a few minutes and by taking the time to make these checks, costly repairs and accidents can be avoided and the equipment will be ready to run should the need arise.For maximum service life of your engine(s), make a thorough inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.

Accumulated grease and oil on an engine or deck is a fire hazard. Remove this debris with steam cleaning or high pressure water, Every 2000 Hour interval or each time any significant quantity of fluid is spilled on an engine or deck (platform).

Check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals.* Wipe all fittings, caps and plugs before performing maintenance to reduce the chance of system contamination.* Cooling system and radiator lines and hoses for cracks and loose clamps.* Water pump for coolant leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract. If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal.For removal and installation of the water pump and/or seals, see the Service Manual for this engine or consult your Caterpillar dealer.* Air inlet system hoses, piping and elbows for cracks and loose clamps. Check the condition of all connections and fittings.* Lube system for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose or worn hoses, and loose fuel line clamps and fittings that are properly clamped and tight.* Wiring harness for loose connections, broken, worn or frayed wires.* ECM to cylinder head ground strap for good connection and condition.While operating, frequently observe the engine oil pressure, fuel pressure, coolant temperature and the air cleaner differential readings.All guards must be in place. Repair or replace missing or damaged guards.* Check condition of all belts for cracks, breaks or other damage. Replace if necessary.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break.* Disconnect any battery chargers that are not protected

Inspect Engine for Leaks and Loose Connections

Inspect Engine Before Starting

A walk-around inspection is recommended to ensure the installation is clean and leaks are kept to a minimum. This should only take a few minutes and by taking the time to make these checks, costly repairs and accidents can be avoided and the equipment will be ready to run should the need arise.For maximum service life of your engine(s), make a thorough inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.

Accumulated grease and oil on an engine or deck is a fire hazard. Remove this debris with steam cleaning or high pressure water, Every 2000 Hour interval or each time any significant quantity of fluid is spilled on an engine or deck (platform).

Check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals.* Wipe all fittings, caps and plugs before performing maintenance to reduce the chance of system contamination.* Cooling system and radiator lines and hoses for cracks and loose clamps.* Water pump for coolant leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract. If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal.For removal and installation of the water pump and/or seals, see the Service Manual for this engine or consult your Caterpillar dealer.* Air inlet system hoses, piping and elbows for cracks and loose clamps. Check the condition of all connections and fittings.* Lube system for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose or worn hoses, and loose fuel line clamps and fittings that are properly clamped and tight.* Wiring harness for loose connections, broken, worn or frayed wires.* ECM to cylinder head ground strap for good connection and condition.While operating, frequently observe the engine oil pressure, fuel pressure, coolant temperature and the air cleaner differential readings.All guards must be in place. Repair or replace missing or damaged guards.* Check condition of all belts for cracks, breaks or other damage. Replace if necessary.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break.* Disconnect any battery chargers that are not protected