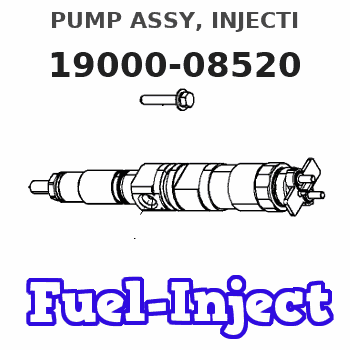

Information pump assy, injecti

Nozzle:

0935002890

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Governor assy, mec | 1908900271 |

| Pump assy, fuel fe | 1922900060 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19000-08520 |

| 002. | BODY ASSY, INJECTI | 09010-05760 |

| 003. | GOVERNOR ASSY, MEC | 09130-00780 |

| 004. | COVER ASSY, GOVERN | 09145-00232 |

| 005. | PUMP ASSY, FUEL FE | 09210-01101 |

| 005. | PUMP ASSY, FUEL FE | 09210-01101 |

| 006. | PUMP ASSY, FUEL FE | 09210-01700 |

Scheme ###:

| 000. | [01] | 19000-08520 | PUMP ASSY, INJECTI | 22100-58290 |

| 001. | [01] | 09010-05760 | BODY ASSY, INJECTI | 22120-58290 |

| 002. | [01] | 09130-00780 | GOVERNOR ASSY, MEC | 22410-58230 |

| 003. | [01] | 09210-01101 | PUMP ASSY, FUEL FE | 22510-56040 |

| 003. | [01] | 09210-01700 | PUMP ASSY, FUEL FE | 22510-873 |

| 008. | [01] | 09001-80090 | COVER, CONTROL RAC | 22116-56230 |

| 008. | [01] | 09001-80220 | COVER, CONTROL RAC | 63031-20061 |

| 009. | [01] | 09257-50150 | SHAFT, SPLINE | 22174-58200 |

| 009. | [01] | 09257-50170 | SHAFT, SPLINE | 22174-58201 |

| 010. | [01] | 09001-20190 | NUT, TIMER ROUND | 22611-58200 |

| 011. | [01] | 94901-50590 | WASHER, SPRING | 90099-01449 |

| 012. | [01] | 94913-00210 | KEY, WOODRUFF | 90099-13023 |

| 013. | [01] | 09048-10030 | CLAMP, HOSE | 90929-01132 |

| 015. | [01] | 91418-06161 | BOLT, W/WASHER | 90091-20614 |

| 016. | [01] | 91418-06201 | BOLT, W/WASHER | 90091-20608 |

| 017. | [03] | 94904-72690 | BOLT, W/WASHER | 90099-04319 |

| 017. | [04] | 94904-72690 | BOLT, W/WASHER | 90099-04319 |

| 018. | [01] | 94904-72990 | BOLT, W/WASHER | 90099-04320 |

| 019. | [01] | 94904-04300 | BOLT, HEXAGON | 90031-01132 |

| 019. | [01] | 94904-73910 | BOLT, W/WASHER | 90099-04346 |

| 020. | [01] | 90258-08001 | WASHER, SPRING | 94511-00800 |

| 021. | [01] | 08601-30120 | NIPPLE | 23323-56020 |

Include in #3:

19000-08520

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-08520 | 22100-5829 | PUMP ASSY, INJECTI | |

| 22100-58290 | TOYOTA | PUMP ASSY, INJECTI |

Information:

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before performing maintenance to keep dirt and debris from entering engine components. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps. * Inspect the fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a 2 or 3 belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers. * Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. * Inspect wiring for loose connections and worn or frayed wires. * Inspect air intake system hoses and elbows for cracks and loose clamps. * Inspect ECM to cylinder head ground strap for good connection and condition.* Inspect engine-to-frame ground strap for good connection and condition.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Check Oil Level

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the crankcase lube oil system.

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to Calibrating the oil level gauge in the Dipstick section of this manual or consult your Caterpillar dealer before changing oil and operating the engine. 3. Remove

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before performing maintenance to keep dirt and debris from entering engine components. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps. * Inspect the fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a 2 or 3 belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers. * Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. * Inspect wiring for loose connections and worn or frayed wires. * Inspect air intake system hoses and elbows for cracks and loose clamps. * Inspect ECM to cylinder head ground strap for good connection and condition.* Inspect engine-to-frame ground strap for good connection and condition.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Check Oil Level

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the crankcase lube oil system.

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to Calibrating the oil level gauge in the Dipstick section of this manual or consult your Caterpillar dealer before changing oil and operating the engine. 3. Remove