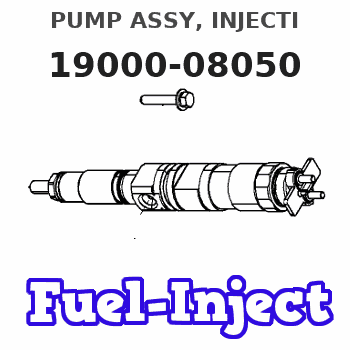

Information pump assy, injecti

Nozzle:

0935002180

Rating:

KIT List:

| Body assy, injecti | 1904400380 |

| Governor assy, mec | NO APPLICATION |

| Timer assy, automa | 0918030010 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19000-08050 |

| 002. | BODY ASSY, INJECTI | 09010-04131 |

| 003. | COVER, BEARING | 09020-10430 |

| 004. | GOVERNOR ASSY, MEC | 09080-08790 |

| 005. | TIMER ASSY, AUTOMA | 09180-01271 |

| 005. | TIMER ASSY, AUTOMA | 09180-01271 |

| 006. | PUMP ASSY, FUEL FE | 09210-00942 |

| 007. | COUPLING ASSY | 09250-00334 |

| 007. | COUPLING ASSY | 09250-00334 |

| 008. | COUPLING ASSY | 09250-00681 |

Scheme ###:

| 000. | [01] | 19000-08050 | PUMP ASSY, INJECTI | 22030-1541 |

| 003. | [01] | 09010-04132 | BODY ASSY, INJECTI | 22110-1700A |

| 004. | [01] | 09080-08790 | GOVERNOR ASSY, MEC | 22330-1750A |

| 005. | [02] | 94904-70620 | BOLT, W/WASHER | 22815-1620A |

| 006. | [01] | 09001-80330 | COVER, CONTROL RAC | 22114-1140A |

| 007. | [01] | 09180-01271 | TIMER ASSY, AUTOMA | 22510-1460A |

| 008. | [01] | 09001-20230 | NUT, TIMER ROUND | 22825-1110A |

| 009. | [01] | 90801-40280 | O-RING | 22817-1050A |

| 010. | [01] | 94901-40070 | WASHER, COUNTERSUN | 22877-1190A |

| 011. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 012. | [01] | 09210-00942 | PUMP ASSY, FUEL FE | 22570-1220A |

| 013. | [01] | 09006-10030 | COVER, PRIMING PUM | 22561-1040 |

| 014. | [01] | 94901-81550 | WASHER, COPPER PLA | 96542-2150A |

| 016. | [01] | 09250-00334 | COUPLING ASSY | 22610-1280B |

| 016. | [01] | 09250-00681 | COUPLING ASSY | 22610-1480A |

| 017. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 018. | [01] | 09031-00050 | VALVE ASSY, OVERFL | 22107-1190A |

| 018. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 021. | [02] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 022. | [04] | 91518-06161 | BOLT, W/WASHER | 22815-1310A |

Include in #3:

19000-08050

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-08050 | 22030-1541 | PUMP ASSY, INJECTI | |

| 22030-1541 | HINO | PUMP ASSY, INJECTI |

Information:

The red lamp should stay ON to indicate that the engine is not protected if the switch is left in the OFF position after the repairs have been made.

Alarm Testing

During testing, abnormal operating conditions must be simulated. Perform the tests correctly to prevent possible damage to the engine.

All alarms on the engine should be tested twice a year for proper operation by referring to the Service Manual and/or contacting your authorized Caterpillar dealer.The controls should be tested every 1000 hours by authorized Caterpillar dealer personnel. Every 500 hours, the Hydramechanical Shutoff (HMSO, early engines) can be tested remotely by engine personnel.Determining Cause of Shutdown or Alarm

There are different conditions that may cause the alarm systems, usually found on an engine, to be activated. Causes for the alarm to function should be followed by performing corrective measures. Additional measures may be required by the operator, depending upon circumstances and conditions present. An authorized Caterpillar dealer should analyze major engine problems. On multi-engine powered vessels, one engine may be shut down for repairs while proceeding at reduced power on the remaining engine(s).Alarm Contactors

The engine is equipped with standard electrical overspeed switch which uses a flywheel housing mounted magnetic pickup. The magnetic pickup will close the circuit and the alarm will be activated when the engine exceeds the setpoint rpm. This engine may be equipped with a Coolant Level Alarm contactor. An Oil Pressure and Coolant Temperature Alarm contactors are optional.Alarm switches are electrically connected to an indicator light, bell or horn. When an alarm is activated, it is an indication of a potential problem and corrective measures must be taken before the situation becomes an emergency. While these alarm switches do not stop the engine, the problem should be investigated and corrective action taken to prevent engine damage.The alarm will continue until the condition is corrected. Then the light will turn off and the bell or horn will be silenced.To silence the bell or horn while repairs are being made, a two-way switch and a red indicator light may be installed. The red indicator light will come on when the alarm is turned off. The red light will stay on, to indicate that the engine is NOT protected, if the switch is left in the OFF position after the repairs have been made.Low Oil Pressure Switch (Early Engines)

The switch will not protect the system from rapid oil loss, caused by failures such as line breakage.

Low oil pressure switchThis device is usually mounted on the side of the engine. The oil lines are connected to the switch. Low oil pressure closes the switch. To reset the switch, push the RESET button in the junction box until it latches. After the engine starts and develops oil pressure, the button will move to the extended (running) position.

The button must be in the RUN position to protect the engine. If the button remains in the OFF position, the engine oil pump may not be developing normal oil pressure and proper checks should be made.

Manually