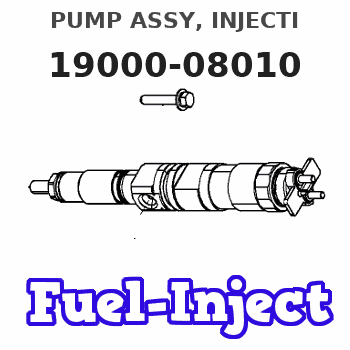

Information pump assy, injecti

Nozzle:

0935002540

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Governor assy, mec | 1908900170 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19000-08010 |

| 002. | BODY ASSY, INJECTI | 09010-05391 |

| 003. | GOVERNOR ASSY, MEC | 09080-08750 |

| 004. | PUMP ASSY, FUEL FE | 09210-01510 |

Scheme ###:

| 000. | [01] | 19000-08010 | PUMP ASSY, INJECTI | 22030-1750 |

| 000. | [01] | 19000-08010 | PUMP ASSY, INJECTI | S2203-01750 |

| 004. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80290 | COVER, CONTROL RAC | 22114-1020A |

| 008. | [01] | 91418-06141 | BOLT, W/WASHER | 22815-1480A |

| 008. | [01] | 91518-06121 | BOLT, W/WASHER | 22815-2740A |

| 009. | [01] | 09006-00150 | COVER SUB-ASSY, TI | 22825-1470A |

| 010. | [05] | 91418-06161 | BOLT, W/WASHER | 22815-1380A |

| 011. | [01] | 91518-08221 | BOLT, W/WASHER | 22815-1190A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09255-10420 | BLOCK, COUPLING | 22630-1030A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 94913-00210 | KEY, WOODRUFF | 22895-1010A |

| 018. | [01] | 09010-05391 | BODY ASSY, INJECTI | 22110-1980B |

| 021. | [01] | 09210-01510 | PUMP ASSY, FUEL FE | 22570-1240A |

| 022. | [04] | 09241-70060 | WASHER, COUPLING S | 22867-1490A |

| 023. | [01] | 09080-08750 | GOVERNOR ASSY, MEC | 22330-1800A |

| 027. | [04] | 94905-02680 | NUT, HEXAGON | 22825-2070A |

| 029. | [04] | 94901-15020 | WASHER, STEEL PLAT | 22877-1551A |

| 030. | [04] | 94904-04870 | BOLT, HEXAGON | 22815-2380A |

Include in #3:

19000-08010

as PUMP ASSY, INJECTI

19000-08010

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-08010 | 22030-1750 | PUMP ASSY, INJECTI | |

| 22030-1750 | HINO | PUMP ASSY, INJECTI | |

| S2203-01750 | HINO | PUMP ASSY, INJECTI |

Information:

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems. Refer to topic, Cold Weather Operation, for additional information.Sulfur

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that are formulated to neutralize these acids. The measure of this reserve alkalinity in a lubricating oil is known as its Total Base Number (TBN). TBN values are essential to neutralize the acids from combustion gases and to minimize corrosive wear.Fuels containing 0.5% total weight or LESS sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils. With sulfur ABOVE the 0.5% level, use API CF-4 performance oils with an ASTM D2896 Total Base Number (TBN) of 10 times the fuel sulfur for DI engines and 20 times for PC engines for normal oil drain intervals. ASTM Specs can normally be found at your local technological society, library or college.Caterpillar recommends infrared analysis (in conjunction with wear metal analysis) of used oil in determining the effectiveness of oil TBN and acid neutralization. The Caterpillar dealer S O S program provides this information. Regular oil analysis (S O S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Periodically request fuel sulfur content information from your fuel supplier. Fuel sulfur content can change with each bulk delivery. American Petroleum Institute (API) classification performance oils should have sufficient TBN for fuels with less than 0.5% sulfur. Fuels containing 0.5% or less sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be used when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.For more information on fuel selection and fuel properties, refer to Diesel Fuels and Your Engine, SEBD0717 or contact your Caterpillar dealer.

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems. Refer to topic, Cold Weather Operation, for additional information.Sulfur

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that are formulated to neutralize these acids. The measure of this reserve alkalinity in a lubricating oil is known as its Total Base Number (TBN). TBN values are essential to neutralize the acids from combustion gases and to minimize corrosive wear.Fuels containing 0.5% total weight or LESS sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils. With sulfur ABOVE the 0.5% level, use API CF-4 performance oils with an ASTM D2896 Total Base Number (TBN) of 10 times the fuel sulfur for DI engines and 20 times for PC engines for normal oil drain intervals. ASTM Specs can normally be found at your local technological society, library or college.Caterpillar recommends infrared analysis (in conjunction with wear metal analysis) of used oil in determining the effectiveness of oil TBN and acid neutralization. The Caterpillar dealer S O S program provides this information. Regular oil analysis (S O S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Periodically request fuel sulfur content information from your fuel supplier. Fuel sulfur content can change with each bulk delivery. American Petroleum Institute (API) classification performance oils should have sufficient TBN for fuels with less than 0.5% sulfur. Fuels containing 0.5% or less sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be used when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.For more information on fuel selection and fuel properties, refer to Diesel Fuels and Your Engine, SEBD0717 or contact your Caterpillar dealer.