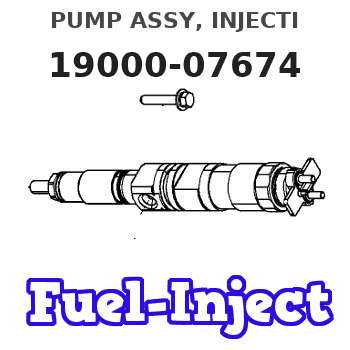

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-07674 |

| 001. | PUMP ASSY, INJECTI | 19000-07674 |

| 002. | BODY ASSY, INJECTI | 09010-05700 |

| 003. | BODY ASSY, INJECTI | 09010-09960 |

| 004. | GOVERNOR ASSY, MEC | 09130-00841 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 006. | PUMP ASSY, FUEL FE | 09210-01440 |

Scheme ###:

| 000. | [01] | 19000-07673 | PUMP ASSY, INJECTI | ME035615 |

| 000. | [01] | 19000-07674 | PUMP ASSY, INJECTI | ME035615 |

| 005. | [01] | 09010-05700 | BODY ASSY, INJECTI | ME702012 |

| 005. | [01] | 09010-09960 | BODY ASSY, INJECTI | ME736047 |

| 006. | [01] | 09130-00841 | GOVERNOR ASSY, MEC | ME702013 |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | ME702034 |

| 008. | [01] | 94914-02840 | O-RING | MH035502 |

| 009. | [01] | 09006-00050 | COVER SUB-ASSY, TI | ME036902 |

| 010. | [01] | 09180-01281 | TIMER ASSY, AUTOMA | ME036901 |

| 011. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 011. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 012. | [05] | 90258-10001 | WASHER, SPRING | MC327716 |

| 013. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 014. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 015. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 016. | [01] | 09001-20220 | NUT, TIMER ROUND | ME702033 |

| 017. | [01] | 09210-01440 | PUMP ASSY, FUEL FE | ME035928 |

| 018. | [01] | 09009-20100 | BRACKET | ME702036 |

| 019. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 020. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 021. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 022. | [01] | 09028-50021 | CAP | ME035845 |

| 023. | [01] | 09009-20140 | BRACKET | ME702037 |

| 024. | [01] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 025. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

19000-07674

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-07674 | ME035615 | PUMP ASSY, INJECTI |

Information:

This chart provides the lubrication and maintenance requirements for your Caterpillar truck engine. Adherence to the instructions and schedules will assure many miles of economical and trouble-free service. 1674

This chart provides the lubrication and maintenance requirements for your Caterpillar truck engine. Adherence to the instructions and schedules will assure many miles of economical and trouble-free service. 1693

This chart provides the lubrication and maintenance requirements for your Caterpillar truck engine. Adherence to the instructions and schedules will assure many miles of economical and trouble-free service. Air Cleaner (Engine)

The engine may be equipped with a dry-type or an oil-bath air cleaner. Service the engine air cleaner at regular intervals determined by dust conditions.If equipped with a dry-type air cleaner, a service indicator is usually mounted on the dash panel. A colored piston showing in the window indicates need for service. Clean or replace filter element. Replace dry-type filter element at least once a year. After servicing, reset indicator by pushing on piston plunger.With an oil-bath cleaner, clean the bottom of the pan with solvent or clean diesel fuel. Fill with engine oil to level indicated by mark on pan. When servicing filter, clean the air pipe inlet cap and wash screens in solvent. Dry thoroughly before installing.NEVER SERVICE THE AIR CLEANER WHILE THE ENGINE IS RUNNING.Air Cleaner (Air Compressor)

The time to replace the air compressor air cleaner (on engines so equipped) is determined by inspection. Inspect at intervals given in the Lubrication and Maintenance charts. Install a new element if plugged or oil soaked. Replace element every 20,000 miles (32 000 km) regardless of condition.Battery

Test the battery electrolyte, at each oil change, with a hydrometer. Always test battery before adding water. A specific gravity difference exceeding .050 between cells indicates the battery may soon need replacing.Maintain water level 3/8" (9.5 mm) above the separators or insulators. Do not overfill the battery.The make-up water must be one of the following (in order of preference).1. Distilled water2. Odorless, tasteless drinking water3. Iron free waterBelt Adjustment

Check new belts for adjustment after the first 500 to 1000 miles (800 to 1600 km) of use, thereafter annually. To check belts, apply 25 lbs. (11 kg) force midway between pulleys. Correctly adjusted belts will deflect 1/2 to 3/4 inch (13 to 19 mm).Cooling System

INHIBITOR CONTAINS ALKALI. Avoid contact with eyes. Avoid prolonged or repeated contact with skin. Do not take internally. In case of contact, immediately wash skin with soap and water. For eyes, flush with large amounts of water for at least 15 minutes. CALL PHYSICIAN. KEEP OUT OF REACH OF CHILDREN.

Do not use with Dowtherm 209.

Before placing the engine in operation, make sure a 3% concentration of Caterpillar Corrosion Inhibitor or equivalent has been added to the cooling system. This 3% concentration must be maintained in cooling systems which are filled with water and systems protected with ethylene glycol antifreeze mixture, regardless of antifreeze concentration.Every 3 months, 500 service hours or 25,000 miles (40,000 km) whichever occurs first, add corrosion inhibitor to maintain the

This chart provides the lubrication and maintenance requirements for your Caterpillar truck engine. Adherence to the instructions and schedules will assure many miles of economical and trouble-free service. 1693

This chart provides the lubrication and maintenance requirements for your Caterpillar truck engine. Adherence to the instructions and schedules will assure many miles of economical and trouble-free service. Air Cleaner (Engine)

The engine may be equipped with a dry-type or an oil-bath air cleaner. Service the engine air cleaner at regular intervals determined by dust conditions.If equipped with a dry-type air cleaner, a service indicator is usually mounted on the dash panel. A colored piston showing in the window indicates need for service. Clean or replace filter element. Replace dry-type filter element at least once a year. After servicing, reset indicator by pushing on piston plunger.With an oil-bath cleaner, clean the bottom of the pan with solvent or clean diesel fuel. Fill with engine oil to level indicated by mark on pan. When servicing filter, clean the air pipe inlet cap and wash screens in solvent. Dry thoroughly before installing.NEVER SERVICE THE AIR CLEANER WHILE THE ENGINE IS RUNNING.Air Cleaner (Air Compressor)

The time to replace the air compressor air cleaner (on engines so equipped) is determined by inspection. Inspect at intervals given in the Lubrication and Maintenance charts. Install a new element if plugged or oil soaked. Replace element every 20,000 miles (32 000 km) regardless of condition.Battery

Test the battery electrolyte, at each oil change, with a hydrometer. Always test battery before adding water. A specific gravity difference exceeding .050 between cells indicates the battery may soon need replacing.Maintain water level 3/8" (9.5 mm) above the separators or insulators. Do not overfill the battery.The make-up water must be one of the following (in order of preference).1. Distilled water2. Odorless, tasteless drinking water3. Iron free waterBelt Adjustment

Check new belts for adjustment after the first 500 to 1000 miles (800 to 1600 km) of use, thereafter annually. To check belts, apply 25 lbs. (11 kg) force midway between pulleys. Correctly adjusted belts will deflect 1/2 to 3/4 inch (13 to 19 mm).Cooling System

INHIBITOR CONTAINS ALKALI. Avoid contact with eyes. Avoid prolonged or repeated contact with skin. Do not take internally. In case of contact, immediately wash skin with soap and water. For eyes, flush with large amounts of water for at least 15 minutes. CALL PHYSICIAN. KEEP OUT OF REACH OF CHILDREN.

Do not use with Dowtherm 209.

Before placing the engine in operation, make sure a 3% concentration of Caterpillar Corrosion Inhibitor or equivalent has been added to the cooling system. This 3% concentration must be maintained in cooling systems which are filled with water and systems protected with ethylene glycol antifreeze mixture, regardless of antifreeze concentration.Every 3 months, 500 service hours or 25,000 miles (40,000 km) whichever occurs first, add corrosion inhibitor to maintain the