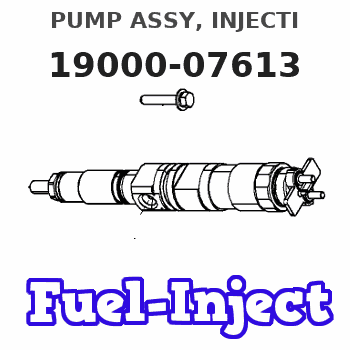

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-07613 |

| 002. | BODY ASSY, INJECTI | 09010-05180 |

| 003. | GOVERNOR ASSY, MEC | 09130-00540 |

| 004. | COVER ASSY, GOVERN | 09145-00154 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 005. | TIMER ASSY, AUTOMA | 09180-01281 |

| 006. | PUMP ASSY, FUEL FE | 09210-00990 |

| 006. | PUMP ASSY, FUEL FE | 09210-00990 |

| 007. | PUMP ASSY, FUEL FE | 09210-01440 |

Scheme ###:

| 000. | [01] | 19000-07613 | PUMP ASSY, INJECTI | ME035737 |

| 005. | [01] | 09010-05181 | BODY ASSY, INJECTI | |

| 006. | [01] | 09130-00543 | GOVERNOR ASSY, MEC | |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | ME702034 |

| 008. | [01] | 94914-02840 | O-RING | MH035502 |

| 009. | [01] | 09006-00190 | COVER SUB-ASSY, TI | |

| 010. | [01] | 09009-20140 | BRACKET | ME702037 |

| 011. | [01] | 09210-00990 | PUMP ASSY, FUEL FE | ME036900 |

| 011. | [01] | 09210-01440 | PUMP ASSY, FUEL FE | ME035928 |

| 012. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 015. | [01] | 09009-20100 | BRACKET | ME702036 |

| 016. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 017. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 018. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 019. | [01] | 09001-20220 | NUT, TIMER ROUND | ME702033 |

| 020. | [01] | 09180-01281 | TIMER ASSY, AUTOMA | ME036901 |

| 021. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 023. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 025. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 026. | [01] | 09006-10011 | COVER, PRIMING PUM | ME022307 |

Include in #3:

19000-07613

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-07613 | ME035737 | PUMP ASSY, INJECTI |

Information:

Never add coolant to an overheated engine; allow the engine to cool first.Check specific gravity of antifreeze solution frequently in cold weather to assure adequate protection.Coolant should be drained and replaced "Every 2000 Service Meter Units." With additions of Caterpillar Cooling System Inhibitor or the use of Coolant Conditioner Elements as recommended, the drain period can be extended to "Every 4000 Service Meter Units."All water is corrosive at engine operating temperature. The cooling system should be protected with inhibitor at all times regardless of concentration of antifreeze. This can be done by maintaining a 3% concentration of liquid Caterpillar Cooling System Inhibitor or by using Coolant Conditioner Elements.Never use both the liquid cooling system inhibitor and coolant elements at the same time.Do not use Caterpillar Cooling System Inhibitor or Coolant Conditioner Elements with Dowtherm 209 Full-Fill Coolant.

Whenever draining and refilling cooling system, always recheck the coolant level when the engine reaches normal operating temperature.Filling at over 5 U.S. gallons (19 liters) per minute can cause air pockets in the cooling system.Premix antifreeze solution to provide protection to the lowest expected ambient temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C).Operate with a thermostat in the cooling system all year-round. Cooling system problems can arise without a thermostat.Electrical

When using jumper cables to start the engine, be sure to connect in parallel: POSITIVE (+) to POSITIVE (+) and NEGATIVE (-) to NEGATIVE (-).

Scheduled Oil Sampling

Use Scheduled Oil Sampling to monitor the engine's condition and maintenance requirements.Each oil sample should be taken when the oil is hot, and well mixed, to insure a sample which is representative of the oil in the compartment.Consult your Caterpillar dealer for complete information, and assistance in establishing a Scheduled Oil Sampling program for your equipment.Fuel

Fill fuel tank at the end of each day of operation to drive out moisture laden air and to prevent condensation. Do not fill the tank to the brim. The fuel expands when it gets warm and may overflow.

Water and sediment should be drained from the fuel tank at the start of each shift or after the fuel tank has been filled and allowed to stand for 5 to 10 minutes.Drain fuel tank of moisture and sediment as required by prevailing conditions.After changing fuel filters, always bleed fuel system to remove air bubbles from system.Air Intake

Service air cleaners when RED band in indicator locks in visible position.