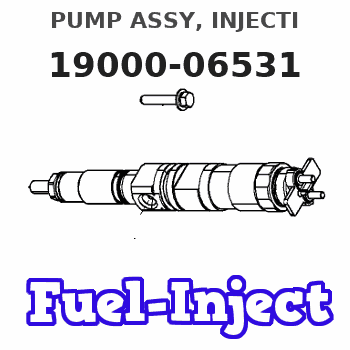

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-06531 |

| 002. | BODY ASSY, INJECTI | 09010-03961 |

| 003. | PUMP ASSY, FUEL FE | 09210-01011 |

Scheme ###:

| 000. | [01] | 19000-06531 | PUMP ASSY, INJECTI | 34661-01091 |

| 005. | [01] | 09010-03961 | BODY ASSY, INJECTI | |

| 006. | [01] | 09080-07121 | GOVERNOR ASSY, MEC | |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | 09001-80081 |

| 008. | [01] | 94905-02450 | NUT, HEXAGON | 94905-02450 |

| 009. | [01] | 94913-00190 | KEY, WOODRUFF | 94913-00190 |

| 010. | [01] | 94901-50500 | WASHER, SPRING | 94901-50500 |

| 012. | [01] | 09210-01011 | PUMP ASSY, FUEL FE | 34461-00303 |

| 013. | [06] | 94904-70620 | BOLT, W/WASHER | |

| 014. | [01] | 90200-06511 | WASHER, PLATE |

Include in #3:

19000-06531

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-06531 | 34661-0109 | PUMP ASSY, INJECTI |

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Turn the crankshaft until the timing mark (C) on the crankshaft gear (1) is in alignment with the timing mark (C) on camshaft gear (2).2. Make a mark on the teeth of the fuel pump drive gear and the idler gear in their engaged position at location (X). Make a mark on the engaged teeth of idler gear and camshaft gear at location (Y). This will give assistance in the correct timing of the camshaft for the fuel injection pump during crankshaft installation. 3. Fasten a hoist to the crankshaft.4. Remove the caps for the main bearings.5. Remove the crankshaft. Weight of the crankshaft is 95 kg (210 lb.).6. Remove the main bearings from the main bearing caps. Remove the crankshaft main bearings from the cylinder block. 7. Use tool (A) to remove the crankshaft gear and the oil seal wear sleeve.Install Crankshaft

Install the bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.

Make sure the upper and lower halves of the main bearings are installed so the bearing tabs fit into the notch in the cylinder block and main bearing caps.

1. Clean the bearing surfaces in the cylinder block. Install the upper halves of the main bearings in the block.2. Heat the crankshaft gear to a maximum temperature of 315° C (600° F). Install the gear on the crankshaft. Fasten a hoist to the crankshaft and put the crankshaft in position in the cylinder block with all timing marks in alignment.3. Clean the bearing surfaces of the main bearing caps. Install the lower halves of the main bearings in the caps. When the bearing clearance is checked and the engine is in a vertical position, such as in the vehicle, the crankshaft will have to be lifted up and held against the upper halves of the main bearings to get a correct measurement with the Plastigage. The Plastigage will not hold the weight of the crankshaft and give a correct indication. If the engine is in a horizontal position, it is not necessary to hold the crankshaft up. Do not turn the crankshaft when the Plastigage is in position to check clearances. 4. Check the main bearing clearances with Plastigage (B) as follows:a. Put a piece of Plastigage (B) in position as shown.

Make sure the part number on the main bearing cap is toward the front of the engine and the number on the main bearing cap is the same as the number on the cylinder block on the left side of each main bearing cap.

Do not turn the crankshaft when Plastigage (B) is in position.b. Install the main bearing caps. Put 2P2506 Thread Lubricant on the bolt threads and the face of the washers and install the bolts. Tighten the bolts to a torque of 40 4 N m (30 3 lb ft).

Do not use an