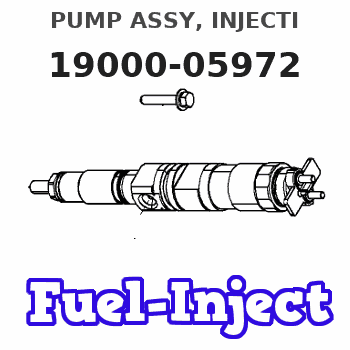

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 19000-05972 |

| 002. | BODY ASSY, INJECTI | 09010-02850 |

| 003. | GOVERNOR ASSY, MEC | 09080-07030 |

| 004. | PUMP ASSY, FUEL FE | 09210-00580 |

| 005. | COUPLING ASSY | 09250-00300 |

Scheme ###:

| 000. | [01] | 19000-05970 | PUMP ASSY, INJECTI | |

| 006. | [01] | 09010-02850 | BODY ASSY, INJECTI | 09010-02850 |

| 007. | [01] | 09080-07030 | GOVERNOR ASSY, MEC | |

| 008. | [06] | 91418-06161 | BOLT, W/WASHER | |

| 009. | [01] | 91518-08221 | BOLT, W/WASHER | 91518-08221 |

| 010. | [01] | 09210-00580 | PUMP ASSY, FUEL FE | 09210-00581 |

| 011. | [01] | 09250-00300 | COUPLING ASSY | 09250-00300 |

| 012. | [01] | 09001-80090 | COVER, CONTROL RAC | |

| 013. | [01] | 09001-20190 | NUT, TIMER ROUND | 09001-20190 |

| 014. | [01] | 94901-50590 | WASHER, SPRING | 94901-50590 |

| 015. | [01] | 94913-00210 | KEY, WOODRUFF | 94913-00210 |

| 016. | [01] | 09006-10011 | COVER, PRIMING PUM | 09006-10011 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-05972 | PUMP ASSY, INJECTI |

Information:

Asphalt CompactorCB-534D (S/N: EAA1-UP; FEA1-UP; GCA1-UP; C2B1-UP; C4B1-UP; FGH1-UP; B5M1-UP; C8M1-UP)CB-564D (S/N: C6D1-UP; D4M1-UP)Asphalt PaverAP-650B (S/N: A7P1-UP)AP-800D (S/N: A5P1-UP)AP300 (S/N: B2Y1-UP)Backhoe Loader414E (S/N: ELB1-UP)416D (S/N: B2D1-UP; BKG1-UP; BGJ1-UP; BFP1-UP)416E (S/N: SHA1-UP; BWC1-UP; CBD1-UP; LMS1-UP)416E Series III (S/N: GRR1-UP)416F (S/N: LWT1-UP)416F2 (S/N: LYA1-UP; LBF1-UP)420D (S/N: BMC1-UP; MBH1-UP; BLN1-UP; FDP1-UP)420E (S/N: GAN1-UP; HLS1-UP; KMW1-UP)420F (S/N: LTG1-UP; LKH1-UP)420F2 (S/N: LBS1-UP)420F2 IT (S/N: LYC1-UP)420F2 ST (S/N: LYB1-UP)422E (S/N: HBE1-UP; DSK1-UP; MAW1-UP)422F (S/N: LRH1-UP)422F2 (S/N: LYF1-UP)424D (S/N: RXA1-UP; CJZ1-UP)426 F2 (S/N: EJ21-UP; DJ41-UP; EJ41-UP)428D (S/N: BXC1-UP; MBM1-UP; DSX1-UP)428E (S/N: DXC1-UP; DPH1-UP; SNL1-UP)428F (S/N: LBH1-UP)428F2 (S/N: LYG1-UP)430D (S/N: BNK1-UP; BML1-UP)430E (S/N: DDT1-UP; EAT1-UP)430F (S/N: LNH1-UP; LDY1-UP)430F2 IT (S/N: LYE1-UP)430F2 ST (S/N: LYD1-UP)432D (S/N: WEP1-UP; TDR1-UP)432E (S/N: JBA1-UP; BXE1-UP; RXS1-UP)432F (S/N: LNR1-UP)432F2 (S/N: LYJ1-UP)434E (S/N: SXB1-UP; SEF1-UP; FSH1-UP; SJL1-UP)434F (S/N: LDH1-UP)434F2 (S/N: LYK1-UP)442D (S/N: TBD1-UP; SMJ1-UP)442E (S/N: EME1-UP; PCR1-UP; GKZ1-UP)444E (S/N: NBA1-UP; HXB1-UP; LBE1-UP)444F (S/N: LJJ1-UP)444F2 (S/N: LYL1-UP)Compact Wheel Loader914G (S/N: PDF1-UP)EngineC3.3 (S/N: E3J1-UP)Excavator312D2 (S/N: EAB1-UP; FAB1-UP; KLE1-UP; DGF1-UP; HBF1-UP; MGJ1-UP; WHJ1-UP; GWN1-UP; MPP1-UP; TJY1-UP)312D2 GC (S/N: BRW1-UP; RXZ1-UP)313D2 (S/N: ZAA1-UP; PLD1-UP; GAJ1-UP; RKN1-UP)318D2 (S/N: JEB1-UP; HAH1-UP; XAH1-UP; DPJ1-UP; WGR1-UP; TZS1-UP; XGS1-UP)320D2 (S/N: GBA1-UP; LCA1-UP; LMA1-UP; YEA1-UP; PBB1-UP; NBF1-UP; TMF1-UP; WBF1-UP; MDJ1-UP; FKK1-UP; DFM1-UP; HDM1-UP; JFM1-UP; TDN1-UP; DNP1-UP; KHR1-UP; RAR1-UP; DNS1-UP; KBS1-UP; ZCS1-UP; EKT1-UP; NBT1-UP; RDZ1-UP; SDZ1-UP; TDZ1-UP)323D3 (S/N: FEY1-UP)Industrial Engine3054C (S/N: 3341-UP)C4.4 (MECH) (S/N: 4461-UP)C7.1 (S/N: 6301-UP; 6731-UP)Integrated ToolcarrierIT14G (S/N: FWL1-UP; KZN1-UP)Mobile Hydraulic Power Unit320D2 MHPU (S/N: K221-UP; P9X1-UP)OEM Excavator Based Specialty Solution312D OEM (S/N: L441-UP)Paving CompactorCB-434D (S/N: CNH1-UP)CD54 (S/N: C3B1-UP; J5R1-UP)CP-323C (S/N: EAS1-UP)CS-323C (S/N: DAR1-UP)PF-300C (S/N: PFB1-UP)PS-150C (S/N: NPK1-UP; FPS1-UP)PS-300C (S/N: PFS1-UP)PS-360C (S/N: PJF1-UP)TelehandlerTH210 (S/N: MHT1-UP)TH215 (S/N: MHS1-UP)Vibratory Soil CompactorCP-433E (S/N: ASN1-UP; BTY1-UP)CP-533E (S/N: BZG1-UP; TLH1-UP; ASM1-UP)CS-433E (S/N: ASR1-UP; BTT1-UP)CS-533E (S/N: BZE1-UP; TBE1-UP; DAK1-UP; ASL1-UP; TJL1-UP)Introduction

There have been some isolated instances of issues with fuel injection pumps on certain 3054C, C3.3, C4.4 (Mech), and C7.1 (Mech) engines. These issues with the fuel injection pump cause the engine to suffer from low power, issues with starting the engine, and excessive smoke.Solution

Ensure that the correct diagnosis procedures have been carried out. Ensure that the following tests have been carried out. Refer to Systems Operation Testing and Adjusting for further information.

Fuel System - Inspect

Air in Fuel - Test

Fuel Injection Nozzle - Test

Fuel Quality - Test

Fuel System - Prime

Fuel System Pressure - TestIf the diagnosis procedures determine that the fuel injection pump has an issue, remove the fuel injection pump from the engine. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove" for the correct procedure. Once the fuel injection pump is removed, follow step1 to step 9 to inspect the fuel injection pump.

Personal injury can result from being struck by parts propelled by a released spring force.Make sure to wear all necessary protective equipment.Follow the recommended procedure and use all recommended tooling to release the spring force.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and

There have been some isolated instances of issues with fuel injection pumps on certain 3054C, C3.3, C4.4 (Mech), and C7.1 (Mech) engines. These issues with the fuel injection pump cause the engine to suffer from low power, issues with starting the engine, and excessive smoke.Solution

Ensure that the correct diagnosis procedures have been carried out. Ensure that the following tests have been carried out. Refer to Systems Operation Testing and Adjusting for further information.

Fuel System - Inspect

Air in Fuel - Test

Fuel Injection Nozzle - Test

Fuel Quality - Test

Fuel System - Prime

Fuel System Pressure - TestIf the diagnosis procedures determine that the fuel injection pump has an issue, remove the fuel injection pump from the engine. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove" for the correct procedure. Once the fuel injection pump is removed, follow step1 to step 9 to inspect the fuel injection pump.

Personal injury can result from being struck by parts propelled by a released spring force.Make sure to wear all necessary protective equipment.Follow the recommended procedure and use all recommended tooling to release the spring force.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and