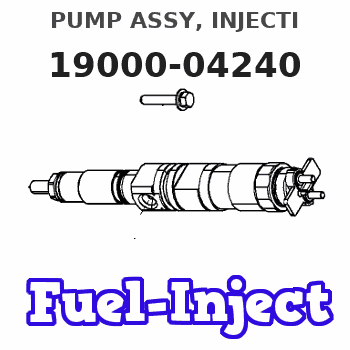

Information pump assy, injecti

Nozzle:

0935001700

Rating:

KIT List:

| Body assy, injecti | 1904400300 |

| Governor assy, mec | 1908900170 |

| Pump assy, fuel fe | 1922900060 |

Components :

| 001. | PUMP ASSY, INJECTI | 19000-04240 |

| 002. | BODY ASSY, INJECTI | 09010-02802 |

| 003. | GOVERNOR ASSY, MEC | 09080-06150 |

| 004. | PUMP ASSY, FUEL FE | 09210-01291 |

Scheme ###:

| 000. | [01] | 19000-04240 | PUMP ASSY, INJECTI | 30461-50060 |

| 005. | [01] | 09010-02802 | BODY ASSY, INJECTI | 34461-00100 |

| 006. | [01] | 09080-06150 | GOVERNOR ASSY, MEC | |

| 007. | [01] | 09001-70030 | SLEEVE SUB-ASSY, L | |

| 008. | [01] | 94905-02450 | NUT, HEXAGON | 94905-02450 |

| 009. | [01] | 94913-00190 | KEY, WOODRUFF | 94913-00190 |

| 010. | [01] | 94901-50500 | WASHER, SPRING | 94901-50500 |

| 012. | [01] | 09210-01291 | PUMP ASSY, FUEL FE | 34461-09060 |

| 013. | [01] | 91518-06121 | BOLT, W/WASHER | 91518-06121 |

| 014. | [05] | 91418-06161 | BOLT, W/WASHER | 91418-06161 |

| 015. | [01] | 91518-08221 | BOLT, W/WASHER | 91518-08221 |

Include in #3:

19000-04240

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 19000-04240 | 30461-5006 | PUMP ASSY, INJECTI | |

| 30461-50060 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Loosen two hose clamps (1) and remove the hose from the tube assembly.2. Remove tube assembly (2) and the gasket.3. Disconnect hose assembly (3). 4. Loosen hose clamps (4) and remove the hose from the pipe. 5. Remove three bolts (6) and engine oil cooler assembly (5). Inspect all gaskets and make replacements if necessary. Install in reverse order.End By:a. install oil filter base

Perform Scheduled Oil Sampling after performing service work to check for coolant leakage and contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Disassemble And Assemble Engine Oil Cooler

Start By:a. remove engine oil cooler

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

Before assembly inspect gaskets and the O-ring seals for damage and make needed replacements. 1. Remove bonnet (1) and pipe (3) from core assembly (2). 2. Remove elbows (4) from the core assembly. Bolts (5) have twelve point heads. 3. Clean the tubes of the cooler core with a 3.96 mm (.156 in) diameter rod. Remove the o-ring seals and inspect for damage. Replace if necessary. Assemble in reverse order.End By:a. install engine oil cooler

Perform Scheduled Oil Sampling after performing service work to check for coolant leakage and contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.