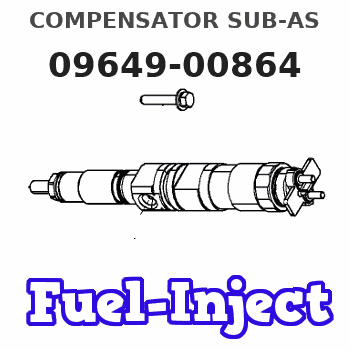

Information compensator sub-as

Rating:

Scheme ###:

| 000. | [01] | 09649-00864 | COMPENSATOR SUB-AS | 22540-17260 |

| 001. | [01] | 09644-00664 | COVER SUB-ASSY, GO | 22703-64850 |

| 002. | [01] | 09644-01320 | COVER SUB-ASSY, GO | 22703-17140 |

| 003. | [01] | 09621-60030 | STOPPER, TIMER SLI | 22658-64518 |

| 004. | [01] | 09646-50630 | R0D, PUSH | 22321-17140 |

| 005. | [01] | 09611-80160 | BUSHING, GUIDE | 22348-64360 |

| 006. | [01] | 19263-10010 | DIAPHRAGM | 22542-54260 |

| 007. | [01] | 09624-80020 | SHIM, PLUNGER SPRI | 22183-54010 |

| 008. | [01] | 09611-80190 | BUSHING, GUIDE | 22348-54490 |

| 009. | [01] | 94905-04070 | NUT, HEXAGON | 90099-05156 |

| 010. | [01] | 09621-10070 | CLIP, TIMER | 22656-54490 |

| 011. | [01] | 09645-50090 | PIN, LEVER CONECTI | 22338-54120 |

| 012. | [01] | 09611-80020 | BUSHING, GUIDE | 22348-54121 |

| 013. | [01] | 09625-40021 | NUT, GOVERNOR SHAF | 22722-54120 |

| 014. | [01] | 94901-81860 | WASHER, COPPER PLA | |

| 015. | [01] | 09604-90230 | O-RING | 22193-55031 |

| 016. | [01] | 09627-20040 | PIN, LEVER SUPPORT | 22526-54120 |

| 017. | [01] | 09629-50080 | LEVER SUB-ASSY, CO | 22308-54140 |

| 017. | [01] | 09629-50680 | LEVER SUB-ASSY, CO | 22308-17570 |

| 018. | [02] | 09024-80010 | WASHER, DRAIN SCRE | 22378-76010 |

| 018. | [02] | 09642-60110 | GASKET, DELIVERY V | 22149-6D450 |

| 019. | [04] | 09644-90130 | BOLT, SOCKET | 22395-54263 |

| 020. | [02] | 09626-90032 | BOLT, GOVERNOR LIN | 22739-54120 |

| 021. | [01] | 09604-90180 | O-RING | 22193-54561 |

| 022. | [01] | 94905-04100 | NUT, HEXAGON | 90099-05181 |

| 022. | [01] | 94905-05430 | NUT, HEXAGON | 90099-05252 |

| 023. | [01] | 90200-08211 | WASHER, PLATE | 90093-00802 |

| 024. | [01] | 90176-06361 | NUT, HEXAGON | 90092-20608 |

| 024. | [01] | 90170-06361 | NUT, HEXAGON | 90092-20604 |

| 025. | [01] | 09602-00110 | SCREW SUB-ASSY, OV | 22160-54262 |

| 026. | [01] | 09024-10010 | WASHER, AIR BLEEDE | 22119-77020 |

| 026. | [01] | 09642-60120 | GASKET, DELIVERY V | 22149-54800 |

| 027. | [01] | 09031-70240 | PLUG, SCREW | 22129-55110 |

| 028. | [1C] | 09649-20520 | SPRING, BOOST COMP | |

| 028. | [1C] | 09649-20150 | SPRING, BOOST COMP | 22546-54490 |

| 028. | [1C] | 09649-20020 | SPRING, BOOST COMP | 22546-5B013 |

| 028. | [ C] | 09649-20160 | SPRING, BOOST COMP | 22546-54491 |

| 029. | [1C] | 09649-30120 | SHIM, BOOST COMPEN | 22547-54267 |

| 029. | [1C] | 09649-30110 | SHIM, BOOST COMPEN | 22547-54266 |

| 029. | [1C] | 09649-30100 | SHIM, BOOST COMPEN | 22547-54265 |

| 029. | [1C] | 09649-30090 | SHIM, BOOST COMPEN | 22547-54490 |

| 029. | [1C] | 09649-30110 | SHIM, BOOST COMPEN | 22547-54266 |

| 029. | [1C] | 09649-30100 | SHIM, BOOST COMPEN | 22547-54265 |

| 029. | [1C] | 09649-30090 | SHIM, BOOST COMPEN | 22547-54490 |

| 029. | [1C] | 09649-30080 | SHIM, BOOST COMPEN | 22547-64361 |

| 029. | [1C] | 09649-30070 | SHIM, BOOST COMPEN | 22547-64360 |

| 029. | [1C] | 09649-30060 | SHIM, BOOST COMPEN | 22547-54268 |

| 029. | [1C] | 09649-30050 | SHIM, BOOST COMPEN | 22547-54264 |

| 029. | [1C] | 09649-30040 | SHIM, BOOST COMPEN | 22547-54263 |

| 029. | [1C] | 09649-30030 | SHIM, BOOST COMPEN | 22547-54262 |

| 029. | [1C] | 09649-30020 | SHIM, BOOST COMPEN | 22547-54261 |

| 029. | [1C] | 09649-30010 | SHIM, BOOST COMPEN | 22547-54260 |

| 030. | [01] | 19263-30010 | WASHER, THRUST | 22549-17140 |

| 031. | [01] | 09646-60090 | SPRING |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09649-00864 | 22540-1726 | COMPENSATOR SUB-AS |

Information:

Introduction

The Fuel Injection Equipment Test Stand (FIETS) is used to efficiently and accurately test all of Caterpillar's fuel injection pumps. These include forged body fuel pumps, compact fuel injection pumps, scroll fuel injection pumps, sleeve metering injection pumps, and 3000 Series fuel pumps.The maintenance and verification procedures in this Tool Operating Manual apply to 6V-7900, 6V-7901, 6V-7902, 6V-7903, 6V-9440, 1U-8212, and 1U-8213 Fuel Injection Equipment Test Stands.Assuring Accuracy

Obtaining accurate and usable results from the FIETS is only possible if the test stand is properly and accurately maintained. If the test stand is not regularly calibrated to factory specifications, the data provided may not be accurate. Test stand maintenance must include testing the quality of the calibration fluid, gauges, and calibration tubes, in addition to changing filters, tightening drive belts, and replacing worn parts.This Tool Operating Manual provides procedures to test, adjust, clean, and maintain the test stand in proper working order. The manual also contains forms to accurately record the history of the maintenance procedures.Remember, test results are only as good as the equipment used to test the fuel injection pump.Test Stand Repair Information

If the test stand needs more than general maintenance or adjusting, contact the original equipment manufacturer. USA and CanadaLucas Aftermarket Operations

1624 Meijer Drive

P.O. Box 7079

Troy, MI 48007-7079

Phone: (810) 288-2000

Fax: (810) 280-8280

A direct technical hotline is also available.

Phone: (810) 280-8301

Fax: (810) 280-8280

All Other LocationsLucas Aftermarket Operations

Great Hampton Street

Birmingham B18 6AU England

Phone: (0)-121-627-7438

Fax: (0)-121-627-7306

Gauge Repair Information

Liquid-filled pressure gauge repair serviceCarrier-Oehler Company

16965 Vincennes Ave.

P.O. Box 40

South Holland, IL 60473-9830

Phone: (708) 339-8200

Fax: (708) 339-9830

Record Keeping And Data Sheets

Blank forms, referred to in this manual, are contained in the "Forms" section. These forms can be copied and used to record the test procedure and maintenance schedule.References

It is important to have and maintain a complete library for the FIETS. This material should include the manuals listed in the "Reference Publications" chart. It is also important to update the manuals as new revisions are available. This will provide the latest and most current reference information. Tooling And Equipment

Test Stand Service Parts

Specifications

Operation Section

Testing A Pump

Bench testing verifies the condition of the plunger and barrel as well as the cam profile. If the plunger and barrel is worn, the delivery rate will be low. Insufficient delivery rates can also be caused by worn cam lobes.Governor settings can also be verified and adjusted using the test stand. Refer to SEHS8200, "Caterpillar Fuel Injection Equipment Test Stand" for complete instructions on testing fuel injection pumps.TMI Data Specifications

Test specification data for newer Caterpillar fuel injection pumps can be found on the Technical Marketing Information (TMI) system. Refer to TMI Manual, LEBQ0724, for additional information on using TMI. Also refer to Tool Operating Manual, NEHS0594, "Using the TMI System to Retrieve Off Engine Injection Pump Test Specifications for the Fuel Injection Equipment Test Stand" for information on using TMI to obtain test specifications using the FIETS.Specific lines and master nozzles must be used for for testing pumps using TMI data. Use the 9U-6705 Master Nozzle with 9U-5298, 9U-5299,

The Fuel Injection Equipment Test Stand (FIETS) is used to efficiently and accurately test all of Caterpillar's fuel injection pumps. These include forged body fuel pumps, compact fuel injection pumps, scroll fuel injection pumps, sleeve metering injection pumps, and 3000 Series fuel pumps.The maintenance and verification procedures in this Tool Operating Manual apply to 6V-7900, 6V-7901, 6V-7902, 6V-7903, 6V-9440, 1U-8212, and 1U-8213 Fuel Injection Equipment Test Stands.Assuring Accuracy

Obtaining accurate and usable results from the FIETS is only possible if the test stand is properly and accurately maintained. If the test stand is not regularly calibrated to factory specifications, the data provided may not be accurate. Test stand maintenance must include testing the quality of the calibration fluid, gauges, and calibration tubes, in addition to changing filters, tightening drive belts, and replacing worn parts.This Tool Operating Manual provides procedures to test, adjust, clean, and maintain the test stand in proper working order. The manual also contains forms to accurately record the history of the maintenance procedures.Remember, test results are only as good as the equipment used to test the fuel injection pump.Test Stand Repair Information

If the test stand needs more than general maintenance or adjusting, contact the original equipment manufacturer. USA and CanadaLucas Aftermarket Operations

1624 Meijer Drive

P.O. Box 7079

Troy, MI 48007-7079

Phone: (810) 288-2000

Fax: (810) 280-8280

A direct technical hotline is also available.

Phone: (810) 280-8301

Fax: (810) 280-8280

All Other LocationsLucas Aftermarket Operations

Great Hampton Street

Birmingham B18 6AU England

Phone: (0)-121-627-7438

Fax: (0)-121-627-7306

Gauge Repair Information

Liquid-filled pressure gauge repair serviceCarrier-Oehler Company

16965 Vincennes Ave.

P.O. Box 40

South Holland, IL 60473-9830

Phone: (708) 339-8200

Fax: (708) 339-9830

Record Keeping And Data Sheets

Blank forms, referred to in this manual, are contained in the "Forms" section. These forms can be copied and used to record the test procedure and maintenance schedule.References

It is important to have and maintain a complete library for the FIETS. This material should include the manuals listed in the "Reference Publications" chart. It is also important to update the manuals as new revisions are available. This will provide the latest and most current reference information. Tooling And Equipment

Test Stand Service Parts

Specifications

Operation Section

Testing A Pump

Bench testing verifies the condition of the plunger and barrel as well as the cam profile. If the plunger and barrel is worn, the delivery rate will be low. Insufficient delivery rates can also be caused by worn cam lobes.Governor settings can also be verified and adjusted using the test stand. Refer to SEHS8200, "Caterpillar Fuel Injection Equipment Test Stand" for complete instructions on testing fuel injection pumps.TMI Data Specifications

Test specification data for newer Caterpillar fuel injection pumps can be found on the Technical Marketing Information (TMI) system. Refer to TMI Manual, LEBQ0724, for additional information on using TMI. Also refer to Tool Operating Manual, NEHS0594, "Using the TMI System to Retrieve Off Engine Injection Pump Test Specifications for the Fuel Injection Equipment Test Stand" for information on using TMI to obtain test specifications using the FIETS.Specific lines and master nozzles must be used for for testing pumps using TMI data. Use the 9U-6705 Master Nozzle with 9U-5298, 9U-5299,