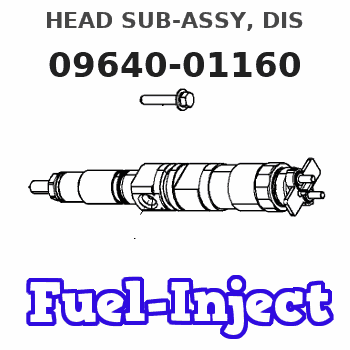

Information head sub-assy, dis

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Cabezales 4/10R Head Rotor VE Pump 096400-1160 22140-5B270 1160 Hydraulic Head and Rotor 10MM 4-Cylinder Right for Fuel Injection Pump 096000-7090 Fits for Diesel Engine 1N-T 1Z

Cabezales Manufacturer MFR No.:096400-1160 , 22140-5B270 Stamping No. 1160 . || Application: Fit for Diesel Engine 1N-T 1Z . || Package: 1 Piece of Pump Head Rotor.Neutral Packing. || Compatible with Fuel Injection Pump: 096000-7090 || Notice:Please Check The No. Before Purchase Firstly,The Number Is Usually Stamped Around Its Body.If You Are Not Sure The No. Or You Have Any Question,Please Do Not Hesitate To Contact Us,We Will Reply You In Time.

Cabezales Manufacturer MFR No.:096400-1160 , 22140-5B270 Stamping No. 1160 . || Application: Fit for Diesel Engine 1N-T 1Z . || Package: 1 Piece of Pump Head Rotor.Neutral Packing. || Compatible with Fuel Injection Pump: 096000-7090 || Notice:Please Check The No. Before Purchase Firstly,The Number Is Usually Stamped Around Its Body.If You Are Not Sure The No. Or You Have Any Question,Please Do Not Hesitate To Contact Us,We Will Reply You In Time.

VE Pump Rotor Head 4/10R 096400-1160 Fit Intended For Engine 1N-T

Generic spare parts || autoparts || machinery parts || engine parts

Generic spare parts || autoparts || machinery parts || engine parts

You can express buy:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09640-01160 | HEAD SUB-ASSY, DIS | ||

| 22140-5B270 | TOYOTA | HEAD SUB-ASSY, DIS | |

| 22140-5B010 | TOYOTA | HEAD SUB-ASSY, DIS |

Information:

Timing Procedure for the Air Compressor

Follow the instructions below in order to properly time the air compressor on a C7 Engine. The air compressor must first be removed and then installed in order to properly time the air compressor.Removal Procedure for the Air Compressor

Do not disconnect the air lines until the air pressure in the system is at zero. If hose is disconnected under pressure it can cause personal injury.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Remove the air pressure from the air tank.

Drain the coolant from the cooling system into a suitable container for storage or for disposal. Refer to Operation and Maintenance Manual, "Cooling System Coolant (ELC) - Change".

Illustration 1 g01261253

Disconnect tube assembly (1), tube assembly (2), tube assembly (3), and hose assembly (4) .

Illustration 2 g01261257

Attach a suitable lifting device onto air compressor (5). The weight of air compressor (5) is approximately 32 kg (70 lb).

Illustration 3 g01261254

Illustration 4 g01271799

Remove bolts (8) and cover (9). Ensure that the timing mark on the crankshaft of the compressor is positioned between the timing marks on the housing for the compressor. Reinstall cover (9) and bolts (8). Remove bolts (6). Remove bracket (7) .

Illustration 5 g01261261

Remove bolts (10). Remove the air compressor and the O-ring seal from the engine.Installation Procedure for the Air Compressor

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 6 g01261257

Note: Check the O-ring seal for wear or for damage. If necessary, replace the O-ring seal.

Attach a suitable lifting device onto air compressor (5). The weight of air compressor (5) is approximately 32 kg (70 lb). Position the O-ring seal and air compressor (5) onto the engine.

Illustration 7 g01261261

Install bolts (10) .

Illustration 8 g01271799

Illustration 9 g01261254

Remove bolts (8) and cover (9). Ensure that the timing mark on the crankshaft of the compr

Follow the instructions below in order to properly time the air compressor on a C7 Engine. The air compressor must first be removed and then installed in order to properly time the air compressor.Removal Procedure for the Air Compressor

Do not disconnect the air lines until the air pressure in the system is at zero. If hose is disconnected under pressure it can cause personal injury.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Remove the air pressure from the air tank.

Drain the coolant from the cooling system into a suitable container for storage or for disposal. Refer to Operation and Maintenance Manual, "Cooling System Coolant (ELC) - Change".

Illustration 1 g01261253

Disconnect tube assembly (1), tube assembly (2), tube assembly (3), and hose assembly (4) .

Illustration 2 g01261257

Attach a suitable lifting device onto air compressor (5). The weight of air compressor (5) is approximately 32 kg (70 lb).

Illustration 3 g01261254

Illustration 4 g01271799

Remove bolts (8) and cover (9). Ensure that the timing mark on the crankshaft of the compressor is positioned between the timing marks on the housing for the compressor. Reinstall cover (9) and bolts (8). Remove bolts (6). Remove bracket (7) .

Illustration 5 g01261261

Remove bolts (10). Remove the air compressor and the O-ring seal from the engine.Installation Procedure for the Air Compressor

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 6 g01261257

Note: Check the O-ring seal for wear or for damage. If necessary, replace the O-ring seal.

Attach a suitable lifting device onto air compressor (5). The weight of air compressor (5) is approximately 32 kg (70 lb). Position the O-ring seal and air compressor (5) onto the engine.

Illustration 7 g01261261

Install bolts (10) .

Illustration 8 g01271799

Illustration 9 g01261254

Remove bolts (8) and cover (9). Ensure that the timing mark on the crankshaft of the compr