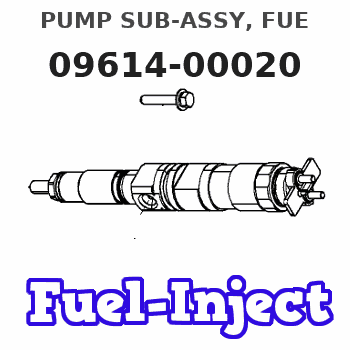

Information pump sub-assy, fue

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Engine Parts Feed Pump 096140-0030 096140-0020 146100-0120 146100-0020 - (Color: 146100-0120)

Generic Color: 146100-0120

Generic Color: 146100-0120

2pcs Feeding Pump Oil Transfer Pump Compatible With Fuel Engine Injection System Models 1461000420 0961400020 1461000720 17mm No Slot

HryJRAW Model: Compatible with 146100-0420/096140-0020/146100-0720 Compatible With precise applications. || Functionality: Designed Compatible With efficient fuel transfer in engine injection systems. || Compatibility: Suitable Compatible With various fuel engine systems, enhancing operational performance. || Design: Features a 17mm dimension and no slot design Compatible With integration. || Set: Comes in a convenient 2-piece set Compatible With comprehensive fuel transfer solutions.

HryJRAW Model: Compatible with 146100-0420/096140-0020/146100-0720 Compatible With precise applications. || Functionality: Designed Compatible With efficient fuel transfer in engine injection systems. || Compatibility: Suitable Compatible With various fuel engine systems, enhancing operational performance. || Design: Features a 17mm dimension and no slot design Compatible With integration. || Set: Comes in a convenient 2-piece set Compatible With comprehensive fuel transfer solutions.

HGHJKZYZ Feeding Pump Compatible with Oil Transfer Pump Models 146100-0420 096140-0020 146100-0720 17mm No Slot Fuel Engine Injection System Replacement Part

HGHJKZYZ Designed Compatible With , this feeding pump is compatible with models 146100-0420, 096140-0020, and 146100-0720, ensuring integration with your fuel engine injection system. || Engineered with a 17mm diameter, this oil transfer pump optimizes fuel flow and enhances engine performance Compatible With a variety of applications. || Constructed without a slot, this pump offers a reliable and straightforward solution Compatible With transferring oils and fuels, the risk of leaks and ensuring efficient. || Ideal Compatible With a wide range of machinery, this feeding pump is suitable Compatible With automotive and industrial applications, making it a versatile addition to your maintenance toolbox. || Crafted from materials, this fuel engine injection system spare part is built to withstand the rigors of demanding environments, ensuring service. || Easy to install, this oil transfer pump helps reduce downtime, allowing you to quickly get your back in without hassle. || Compatible with various fuel systems, this feeding pump is an essential component Compatible With maintaining engine functionality and fuel efficiency.

HGHJKZYZ Designed Compatible With , this feeding pump is compatible with models 146100-0420, 096140-0020, and 146100-0720, ensuring integration with your fuel engine injection system. || Engineered with a 17mm diameter, this oil transfer pump optimizes fuel flow and enhances engine performance Compatible With a variety of applications. || Constructed without a slot, this pump offers a reliable and straightforward solution Compatible With transferring oils and fuels, the risk of leaks and ensuring efficient. || Ideal Compatible With a wide range of machinery, this feeding pump is suitable Compatible With automotive and industrial applications, making it a versatile addition to your maintenance toolbox. || Crafted from materials, this fuel engine injection system spare part is built to withstand the rigors of demanding environments, ensuring service. || Easy to install, this oil transfer pump helps reduce downtime, allowing you to quickly get your back in without hassle. || Compatible with various fuel systems, this feeding pump is an essential component Compatible With maintaining engine functionality and fuel efficiency.

You can express buy:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09614-00020 | S501 24 02 | PUMP SUB-ASSY, FUE | |

| 22505-87701-000 | DAIHATSU | PUMP SUB-ASSY, FUE | |

| S501 24 020 | MAZDA | PUMP SUB-ASSY, FUE |

Information:

If the engine has been operating at high load, run at low idle for at least three minutes before stopping. This cool down will reduce and stabilize internal engine coolant and oil temperatures before stopping the engine.If the engine has been operating at low loads, run the engine at low idle for 30 seconds before stopping.Make sure the shutoff procedure is understood. Refer to the Stopping the Engine instructions in the Generator Set Control Panel topic in this publication. Use the following general guidelines for stopping the engine.1. Open the Main electrical circuit breaker/Remove load from engine.2. Move the governor control to no more than half engine speed. Run the engine for three to five minutes.3. Reduce the engine speed to low idle.4. The engine may be stopped by using the Woodward Governor (if equipped), the Mechanical Governor (if equipped), or the solenoid shutoff switch.Woodward Actuator (If Equipped)

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.