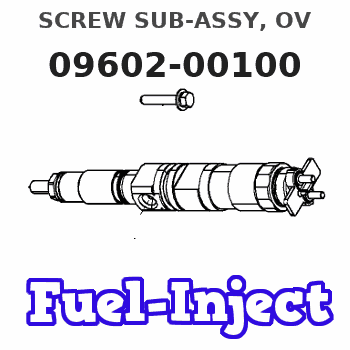

Information screw sub-assy, ov

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Hacus - Forklift FPE249145 Screw SUB-Assy Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus - Forklift FPE247079 Screw SUB-Assy Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09602-00100 | 22160-7830 | SCREW SUB-ASSY, OV | |

| 22160-96300 | TOYOTA | SCREW SUB-ASSY, OV | |

| 22160-78300-71 | TICO | SCREW SUB-ASSY, OV |

Information:

Required Parts

Table 1

Required Parts

Part Number Part Name Quantity

227-1200 Injector Sleeve 6

310-7255 O-Ring Seal 6

310-7257 O-Ring Seal 6 Required Tools

Table 2

Required Tools

Part Number Part Name Quantity

221-9777 Sleeve Installer 1

4C-5552 Large Bore Brush 1

4C-9507 Retaining Compound 1 Cleaning the Injector Sleeves and Installing O-Ring Seal

Note: Thoroughly clean the injector sleeves with the 4C-5552 Large Bore Brush .Note: Thoroughly clean the bore in the cylinder head for the injector sleeves with the 4C-5552 Large Bore Brush .Note: Do not apply any lubricant to the O-ring seals.

Illustration 1 g01379557

(1) 310-7255 O-Ring Seal (2) 310-7257 O-Ring Seal (3) 227-1200 Injector Sleeve

Install the upper O-Ring (1) on the injector sleeve (3) .Note: The upper O-Ring is dark blue.

Install the lower O-Ring (2) on the injector sleeve (3) .Note: The lower O-Ring (2) is turquoise.

Position the injector sleeve on the 221-9777 Sleeve Installer .

Apply a thin coat of 4C-9507 Retaining Compound around the outer circumference of area (A). Ensure that the retaining compound does not make contact with the O-Ring seal at any time.

Position the injector sleeve (3) in the cylinder head by using the 221-9777 Sleeve Installer .

Slowly push the injector sleeve into the cylinder head by gently tapping with a hammer.Note: Allow the 4C-9507 Retaining Compound to cure for two hours at 21 °C (70 °F) before filling the engine with coolant. Longer curing time is required for lower temperatures.

Install the unit injectors. Refer to Disassembly and Assembly, "Unit Injector-Install" to install the unit injectors.

Table 1

Required Parts

Part Number Part Name Quantity

227-1200 Injector Sleeve 6

310-7255 O-Ring Seal 6

310-7257 O-Ring Seal 6 Required Tools

Table 2

Required Tools

Part Number Part Name Quantity

221-9777 Sleeve Installer 1

4C-5552 Large Bore Brush 1

4C-9507 Retaining Compound 1 Cleaning the Injector Sleeves and Installing O-Ring Seal

Note: Thoroughly clean the injector sleeves with the 4C-5552 Large Bore Brush .Note: Thoroughly clean the bore in the cylinder head for the injector sleeves with the 4C-5552 Large Bore Brush .Note: Do not apply any lubricant to the O-ring seals.

Illustration 1 g01379557

(1) 310-7255 O-Ring Seal (2) 310-7257 O-Ring Seal (3) 227-1200 Injector Sleeve

Install the upper O-Ring (1) on the injector sleeve (3) .Note: The upper O-Ring is dark blue.

Install the lower O-Ring (2) on the injector sleeve (3) .Note: The lower O-Ring (2) is turquoise.

Position the injector sleeve on the 221-9777 Sleeve Installer .

Apply a thin coat of 4C-9507 Retaining Compound around the outer circumference of area (A). Ensure that the retaining compound does not make contact with the O-Ring seal at any time.

Position the injector sleeve (3) in the cylinder head by using the 221-9777 Sleeve Installer .

Slowly push the injector sleeve into the cylinder head by gently tapping with a hammer.Note: Allow the 4C-9507 Retaining Compound to cure for two hours at 21 °C (70 °F) before filling the engine with coolant. Longer curing time is required for lower temperatures.

Install the unit injectors. Refer to Disassembly and Assembly, "Unit Injector-Install" to install the unit injectors.