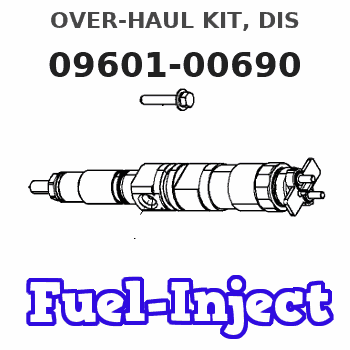

Information over-haul kit, dis

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Solarhome Fuel Shutoff Solenoid 6630546 6632196 9971792 Compatible With Bobcat 843 853 1213 2000

Solarhome Product Name: Fuel Shutoff Solenoid || Part Number: R89014,3313742000,208-5029,096010-0690,096010-0500,0330001018,0330001015,MP20156,MP20142,26420518,876614,716/30211,716/3211,17/918121,A77753,8190393,8100253,0330001042,0330001041,0330001040,44-6727,6630546,9971792,2852741,QR6881390,146650-1220 || Application Models: Compatible With Bobcat 843 853 1213 2000 || Package Include: 1X Fuel Shutoff Solenoid,6630546

Solarhome Product Name: Fuel Shutoff Solenoid || Part Number: R89014,3313742000,208-5029,096010-0690,096010-0500,0330001018,0330001015,MP20156,MP20142,26420518,876614,716/30211,716/3211,17/918121,A77753,8190393,8100253,0330001042,0330001041,0330001040,44-6727,6630546,9971792,2852741,QR6881390,146650-1220 || Application Models: Compatible With Bobcat 843 853 1213 2000 || Package Include: 1X Fuel Shutoff Solenoid,6630546

12V Fuels Pumps Shut Off Solenoid For Heavy Machinery Engine Repair 096030-0070 096010-0690 096030-0160

NSDSW Built with corrosions metal alloy, this solenoid valves withstands high temperatures and frequent operations cycles for long lasting engine performances || Performs reliably in extreme conditions from commutes to heavy duty off roading operations ensuring uninterrupted fuels management in temperature fluctuations || The 12V fuels cut off stop solenoid ensures precise fuels flows control with quick response time, leaks and enhances || Ideal for automotive technicians and DIYer enthusiasts maintaining engines across various industrial equipment and commercial vehicles || Engineered with exact dimension for seamlessly installation in tight engine compartments

NSDSW Built with corrosions metal alloy, this solenoid valves withstands high temperatures and frequent operations cycles for long lasting engine performances || Performs reliably in extreme conditions from commutes to heavy duty off roading operations ensuring uninterrupted fuels management in temperature fluctuations || The 12V fuels cut off stop solenoid ensures precise fuels flows control with quick response time, leaks and enhances || Ideal for automotive technicians and DIYer enthusiasts maintaining engines across various industrial equipment and commercial vehicles || Engineered with exact dimension for seamlessly installation in tight engine compartments

You can express buy:

USD 7.28

14-06-2025

14-06-2025

12V Fuel Pump Solenoid Fuel Cut-Off Stop Solenoid for- . Engine 096030-0070 096010-0690 096030-0160

USD 24

19-05-2025

19-05-2025

6pcs/lot Solenoid valve 7185-900G, 096010-0690, 096010-0700,146650-0720, 146650-0820,146650-3720 MP20143,0330001042 9461612134

Images:

USD 32.5

[13-May-2025]

USD 7.16

[14-Jun-2025]

USD 47

[13-May-2025]

USD 47

[13-May-2025]

Components :

| 001. | OVER-HAUL KIT, DIS | 09601-00690 |

Scheme ###:

| 000. | [01] | 09601-00690 | OVER-HAUL KIT, DIS | 22019-6A511 |

| 001. | [01] | 09603-00520 | SOLENOID ASSY, FUE | 22390-6A511 |

| 001-001. | [01] | 09604-90350 | O-RING | |

| 002. | [01] | 09604-90030 | O-RING | 22193-64010 |

Include in #3:

09600-00600

as OVER-HAUL KIT, DIS

09601-00690

Cross reference number

| Part num | Firm num | Firm | Name |

| 09601-00690 | 22019-6A51 | OVER-HAUL KIT, DIS | |

| 22390-6A511-000 | DAIHATSU | OVER-HAUL KIT, DIS | |

| 22019-6A511-000 | DAIHATSU | OVER-HAUL KIT, DIS | |

| 22019-6A511 | TOYOTA | OVER-HAUL KIT, DIS | |

| ME736821 | MITSUBISHI | OVER-HAUL KIT, DIS |

Information:

Engine

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Keep your engine clean. Remove debris and fluid spills each time a significant quantity accumulates on the engine.

Steam cleaning your engine is a recommended preventive maintenance practice because it provides for easy detection of fluid leaks. Repairing an oil or coolant leak upon detection may save money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

Inspect/Check

1. Remove the exhaust outlet piping and inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine or compressor wheel and the turbocharger housing.Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system.If oil is found only on the back side of the wheel, it indicates a turbo oil seal leak. The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged filters).Maintain the compressor wheel/turbo housing by cleaning with standard shop solvents and a soft bristle brush.6. Check the end play and bearing clearance on the turbine wheel and shaft.If the measurements are not within specifications, the turbocharger must be repaired or replaced.7. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away.Removal and Installation

For removal and installation, or repair/replacement options of turbochargers, see your Caterpillar dealer.Refer to the Service Manual for this engine or consult your Caterpillar dealer for the procedure and specifications.Crankshaft Vibration Damper

Inspect/Check

Damage to, or failure of, the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating vibration damper will cause excessive gear train noise at variable points in the speed range.Visconic Damper (If Equipped)

The vibration damper weight is located inside a fluid filled case. The weight moves in the case to limit torsional vibration. Inspect the dampers for evidence of dents, cracks or leaks of the fluid.Rubber Damper (If Equipped)

The vibration damper can have a visual wobble (movement to the front and rear when in rotation) on the outer ring. This does not mean a replacement is necessary since some wobble of the outer

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Keep your engine clean. Remove debris and fluid spills each time a significant quantity accumulates on the engine.

Steam cleaning your engine is a recommended preventive maintenance practice because it provides for easy detection of fluid leaks. Repairing an oil or coolant leak upon detection may save money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

Inspect/Check

1. Remove the exhaust outlet piping and inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine or compressor wheel and the turbocharger housing.Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system.If oil is found only on the back side of the wheel, it indicates a turbo oil seal leak. The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged filters).Maintain the compressor wheel/turbo housing by cleaning with standard shop solvents and a soft bristle brush.6. Check the end play and bearing clearance on the turbine wheel and shaft.If the measurements are not within specifications, the turbocharger must be repaired or replaced.7. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away.Removal and Installation

For removal and installation, or repair/replacement options of turbochargers, see your Caterpillar dealer.Refer to the Service Manual for this engine or consult your Caterpillar dealer for the procedure and specifications.Crankshaft Vibration Damper

Inspect/Check

Damage to, or failure of, the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating vibration damper will cause excessive gear train noise at variable points in the speed range.Visconic Damper (If Equipped)

The vibration damper weight is located inside a fluid filled case. The weight moves in the case to limit torsional vibration. Inspect the dampers for evidence of dents, cracks or leaks of the fluid.Rubber Damper (If Equipped)

The vibration damper can have a visual wobble (movement to the front and rear when in rotation) on the outer ring. This does not mean a replacement is necessary since some wobble of the outer