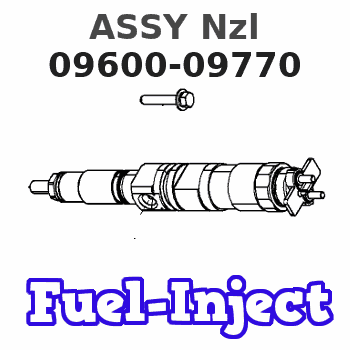

Information assy nzl

Nozzle:

0935006170

Rating:

KIT List:

| Pump assy, injecti | 0960100620 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

VE Pump Diesel Engine Fuel Injection Pump Assembly Professional Diesel Fuel Injection Pump 096000-9770

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

VE Pump Diesel Engine Fuel Injection Pump Assembly Professional Diesel Fuel Injection Pump 096000-9770

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

VE Pump Diesel Engine Fuel Injection Pump Assembly Professional Diesel Fuel Injection Pump 096000-9770

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

You can express buy:

USD 377.89

19-05-2025

19-05-2025

VE Pump Diesel Engine New Fuel Injection Pump Assembly Professional Diesel Fuel Injection Pump 096000-9770

Images:

USD 458.36

[19-May-2025]

USD 434

[29-May-2025]

USD 434

[29-May-2025]

Components :

| 001. | PUMP ASSY, INJECTI | 09600-09770 |

| 002. | RING SUB-ASSY, ROL | 09618-00280 |

| 003. | COVER SUB-ASSY, TI | 09621-01021 |

| 004. | SHIM, PLUNGER ADJU | 09640-60020 |

| 005. | VALVE SUB-ASSY, DI | 09642-00720 |

| 006. | COMPENSATOR SUB-AS | 09649-01300 |

| 007. | COVER SUB-ASSY, GO | 09644-01301 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09600-09770 | ASSY Nzl | ||

| 22100-17890 | TOYOTA | PUMP ASSY, INJECTI |

Information:

If the engine has been operating at high load, run at low idle for at least three minutes before stopping. This cool down will reduce and stabilize internal engine coolant and oil temperatures before stopping the engine.If the engine has been operating at low loads, run the engine at low idle for 30 seconds before stopping.Make sure the shutoff procedure is understood. Refer to the Stopping the Engine instructions in the Generator Set Control Panel topic in this publication. Use the following general guidelines for stopping the engine.1. Open the Main electrical circuit breaker/Remove load from engine.2. Move the governor control to no more than half engine speed. Run the engine for three to five minutes.3. Reduce the engine speed to low idle.4. The engine may be stopped by using the Woodward Governor (if equipped), the Mechanical Governor (if equipped), or the solenoid shutoff switch.Woodward Actuator (If Equipped)

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.