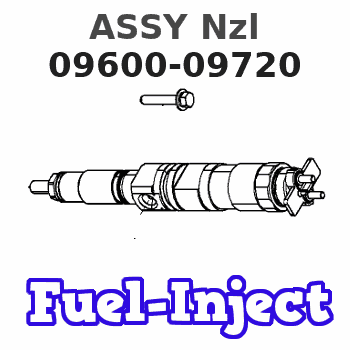

Information assy nzl

Nozzle:

0935006170

Rating:

KIT List:

| Pump assy, injecti | 0960100620 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

New VE Pump 1HD-FT Diesel Engine Fuel Injection Pump 096000-9720 VE6/12F2000RND972 22100-17840 R972

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

New VE Pump 1HD-FT Diesel Engine Fuel Injection Pump 096000-9720 VE6/12F2000RND972 22100-17840 R972

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

WZCNLXLX Fuel Injection Pump 096000-9720 22100-17840 For Land Cruiser 1HD-FT Engine

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-17840 096000-9720 2210017840 0960009720 || Application:For Land Cruiser 1HD-FT Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-17840 096000-9720 2210017840 0960009720 || Application:For Land Cruiser 1HD-FT Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

You can express buy:

USD 411.63

13-05-2025

13-05-2025

New VE Pump 1HD-FT Diesel Engine Fuel Injection Pump 096000-9720 VE6/12F2000RND972 22100-17840 R972

Images:

USD 380.82

[19-May-2025]

USD 459.12

[08-May-2025]

Components :

| 001. | PUMP ASSY, INJECTI | 09600-09720 |

| 002. | RING SUB-ASSY, ROL | 09618-00280 |

| 003. | COVER SUB-ASSY, TI | 09621-01021 |

| 004. | SHIM, PLUNGER ADJU | 09640-60020 |

| 005. | VALVE SUB-ASSY, DI | 09642-00720 |

| 006. | COMPENSATOR SUB-AS | 09649-01280 |

| 007. | COVER SUB-ASSY, GO | 09644-01480 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09600-09720 | ASSY Nzl | ||

| 22100-17840 | TOYOTA | PUMP ASSY, INJECTI |

Information:

Weekly (Before Starting Engine)

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Battery Charger - Check for proper operation Batteries - Clean/Check electrolyte level Air Starter System (if equipped) - Check lubricator oil level, air pressure and drain condensation Engine Air Cleaner - Check service indicator Block Heater - Check for proper operation, maintain 32°C (90°F) temperature Aftercooler - Inspect ATAAC Belts - Inspect/Replace Engine Protection Devices - Inspect system and gauges for proper operation Generator and Control Panel - Inspect componentsWeekly (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections and generator louvers for proper operation Engine Crankcase - Check oil level Oil Pressure - Check gauge reading Generator - Check frequency (rpm) and generated voltageWeekly (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Automatic Switches - Check for proper position to execute auto-start Battery Charger - Record charging amperage readingYearly (Before Starting Engine)*

Cooling System - Check coolant level, Test for concentration of supplemental coolant additive Crankcase Breather - Clean Valve Lash - Check/Adjust Governor - Inspect for leaks Governor Linkage - Check/Adjust and Lubricate Air Inlet Piping - Inspect Engine Air Cleaner - Check service indicator, Replace element if necessary Generator - Lubricate bearingYearly (With Engine Running)*

Engine Protection Devices - Inspect system and gauges for proper operation;/bs/, Record gauge readings Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate the engine at a minimum of 30 percent of rated load for minimum of two hours Engine Mounts - InspectYearly (After Stopping Engine)*

Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - ReplaceEvery Three Years (Before Starting Engine)*

Turbocharger - Inspect/Check bearing end play and radial clearance Governor - Inspect for leaks Thermostat - Replace Coolant Hoses - Replace Cooling System - Clean/Flush coolant Batteries - ReplaceEvery Three Years (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Protection Devices - Inspect system and gauges for proper operation, Record gauge readings Engine Crankcase - Check oil level Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate at a minimum of 30 percent of rated load for minimum of two hours Exhaust System - Check for leaksEvery Three Years (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - Replace Battery Charger - Record charging amp reading Automatic Switches - Check for proper position to execute auto-start Coolant Analysis - ObtainEvery Four Years

Drain/Replace Engine Coolant (Extended Life Coolant Only)*First Perform Previous Maintenance Items

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Battery Charger - Check for proper operation Batteries - Clean/Check electrolyte level Air Starter System (if equipped) - Check lubricator oil level, air pressure and drain condensation Engine Air Cleaner - Check service indicator Block Heater - Check for proper operation, maintain 32°C (90°F) temperature Aftercooler - Inspect ATAAC Belts - Inspect/Replace Engine Protection Devices - Inspect system and gauges for proper operation Generator and Control Panel - Inspect componentsWeekly (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections and generator louvers for proper operation Engine Crankcase - Check oil level Oil Pressure - Check gauge reading Generator - Check frequency (rpm) and generated voltageWeekly (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Automatic Switches - Check for proper position to execute auto-start Battery Charger - Record charging amperage readingYearly (Before Starting Engine)*

Cooling System - Check coolant level, Test for concentration of supplemental coolant additive Crankcase Breather - Clean Valve Lash - Check/Adjust Governor - Inspect for leaks Governor Linkage - Check/Adjust and Lubricate Air Inlet Piping - Inspect Engine Air Cleaner - Check service indicator, Replace element if necessary Generator - Lubricate bearingYearly (With Engine Running)*

Engine Protection Devices - Inspect system and gauges for proper operation;/bs/, Record gauge readings Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate the engine at a minimum of 30 percent of rated load for minimum of two hours Engine Mounts - InspectYearly (After Stopping Engine)*

Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - ReplaceEvery Three Years (Before Starting Engine)*

Turbocharger - Inspect/Check bearing end play and radial clearance Governor - Inspect for leaks Thermostat - Replace Coolant Hoses - Replace Cooling System - Clean/Flush coolant Batteries - ReplaceEvery Three Years (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Protection Devices - Inspect system and gauges for proper operation, Record gauge readings Engine Crankcase - Check oil level Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate at a minimum of 30 percent of rated load for minimum of two hours Exhaust System - Check for leaksEvery Three Years (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - Replace Battery Charger - Record charging amp reading Automatic Switches - Check for proper position to execute auto-start Coolant Analysis - ObtainEvery Four Years

Drain/Replace Engine Coolant (Extended Life Coolant Only)*First Perform Previous Maintenance Items