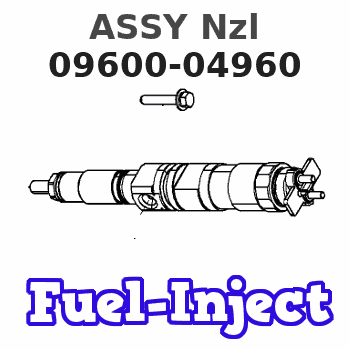

Information assy nzl

Nozzle:

0935004180

Rating:

KIT List:

| Pump assy, injecti | 0960100031 0960100551 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Compatible with Cummins Engine NT855 NT855-DM Fuel Injection Pump 4951350 495-1350 C4951350

KoovDem Part Number:096000-4960 22100-54880 0960004960 || Part Name: Fuel Injection Pump || Compatible with Toyota Hilux models featuring a 2.8L engine, this product is specifically designed to enhance performance and optimize functionality. Ideal for those seeking to upgrade their vehicle's capabilities and maximize efficiency, this component is a perfect fit for Toyota Hilux owners looking to take their driving experience to the next level. || The package contains a single Fuel Injection Pump with part number 096000-4960 (also identified as 22100-54880 or 0960004960).

KoovDem Part Number:096000-4960 22100-54880 0960004960 || Part Name: Fuel Injection Pump || Compatible with Toyota Hilux models featuring a 2.8L engine, this product is specifically designed to enhance performance and optimize functionality. Ideal for those seeking to upgrade their vehicle's capabilities and maximize efficiency, this component is a perfect fit for Toyota Hilux owners looking to take their driving experience to the next level. || The package contains a single Fuel Injection Pump with part number 096000-4960 (also identified as 22100-54880 or 0960004960).

Compatible with Kubota Engine V3300 Fuel Injection Pump Assembly 6680751 for Bobcat Loader A300 S220 S250 S300 T250 T300

KoovDem Part Number:096000-4960 22100-54880 0960004960 || Part Name: Fuel Injection Pump || Absolutely! Engine Specs: The 2.8L engine offers a potent combination of power and efficiency, ideal for diverse vehicle applications. It excels in city driving and long-distance travel, delivering a smooth and responsive performance. Incorporating state-of-the-art technology and design, this engine guarantees reliable and enduring operation, making it a top choice for drivers seeking top-notch performance. || Compatible for Toyota Hilux models equipped with a 2.8L engine. || The package contains a single Fuel Injection Pump with the part number 096000-4960, which is also referred to as 22100-54880 or 0960004960.

KoovDem Part Number:096000-4960 22100-54880 0960004960 || Part Name: Fuel Injection Pump || Absolutely! Engine Specs: The 2.8L engine offers a potent combination of power and efficiency, ideal for diverse vehicle applications. It excels in city driving and long-distance travel, delivering a smooth and responsive performance. Incorporating state-of-the-art technology and design, this engine guarantees reliable and enduring operation, making it a top choice for drivers seeking top-notch performance. || Compatible for Toyota Hilux models equipped with a 2.8L engine. || The package contains a single Fuel Injection Pump with the part number 096000-4960, which is also referred to as 22100-54880 or 0960004960.

Components :

| 001. | PUMP ASSY, INJECTI | 09600-04960 |

| 002. | BELLOWS ASSY, PNEU | 09071-00440 |

| 003. | BELLOWS ASSY, PNEU | 09071-00590 |

| 004. | RING SUB-ASSY, ROL | 09618-00020 |

| 005. | GOVERNOR ASSY, TOR | 09627-00060 |

| 006. | SHIM, PLUNGER ADJU | 09640-60020 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09600-04960 | ASSY Nzl | ||

| 22100-54880 | TOYOTA | PUMP ASSY, INJECTI |

Information:

start by:a) remove fuel injection lines**This operation location is in the ENGINE DISASSEMBLY AND ASSEMBLY section. 1. Disconnect the fuel lines from fuel transfer pump (4) and fuel manifold (3). Disconnect fuel line (2) from the fitting. Disconnect the fuel return line to the tank at (1). Install plugs or caps on all fuel line openings.2. Disconnect drain line (5) from the governor housing. Move the fuel lines and drain line clear of the fuel injection pump housing and governor. 3. Remove bolts (6) that hold the oil manifold to the governor housing. 4. Remove cover (7) from the timing gear cover.5. Remove the bolt and washer that hold the timing gear to the camshaft in the fuel injection pump housing. 6. Install tooling (A) and loosen the timing gear on the camshaft in the fuel injection pump housing.7. Fasten a strap and hoist to the fuel injection pump housing and governor as shown. 8. Remove three nuts (8) and remove the fuel injection pump housing and governor. Weight is 25 kg (56 lb.).Install Fuel Injection Pump Housing And Governor

1. Be sure O-ring seals (1) and (2) are in position on the fuel injection pump housing and governor and put clean oil on the O-ring seals.2. Remove the cover on the fuel injection pump housing and install timing pin (A). Turn the camshaft until timing pin (A) goes in the groove in the camshaft as shown. 3. Fasten a strap and hoist to the fuel injection pump housing and governor and put in position on the timing gear plate and oil manifold (3). Install the three nuts that hold the fuel injection pump housing to the timing gear plate and the two bolts that hold the governor housing to oil manifold (3).

After the fuel injection pump housing and governor are installed on the timing gear plate be sure the rack is free to move. The O-ring seal on the drive end of the fuel injection pump can hold the rack and prevent free movement of the rack. If the rack does not move freely remove the fuel injection pump housing and governor and check the O-ring seal on the drive end of the fuel injection pump housing.

4. Install the bolt and washer (4) as shown to hold the timing gear to the camshaft. Install washer (4) with the larger outside diameter toward the bolt head. Tighten the bolt finger tight only.5. Use the following procedure to put the No. 1 piston at top center on the compression stroke. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of flywheel rotation is given. Do not turn the flywheel backward. a) Remove plug (5) from the flywheel housing and the breather from the valve cover.b) Turn the flywheel counterclockwise until a 3/8"-16 NC bolt (6) at least 2.5 in. long can be installed in the flywheel through the hole in

1. Be sure O-ring seals (1) and (2) are in position on the fuel injection pump housing and governor and put clean oil on the O-ring seals.2. Remove the cover on the fuel injection pump housing and install timing pin (A). Turn the camshaft until timing pin (A) goes in the groove in the camshaft as shown. 3. Fasten a strap and hoist to the fuel injection pump housing and governor and put in position on the timing gear plate and oil manifold (3). Install the three nuts that hold the fuel injection pump housing to the timing gear plate and the two bolts that hold the governor housing to oil manifold (3).

After the fuel injection pump housing and governor are installed on the timing gear plate be sure the rack is free to move. The O-ring seal on the drive end of the fuel injection pump can hold the rack and prevent free movement of the rack. If the rack does not move freely remove the fuel injection pump housing and governor and check the O-ring seal on the drive end of the fuel injection pump housing.

4. Install the bolt and washer (4) as shown to hold the timing gear to the camshaft. Install washer (4) with the larger outside diameter toward the bolt head. Tighten the bolt finger tight only.5. Use the following procedure to put the No. 1 piston at top center on the compression stroke. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of flywheel rotation is given. Do not turn the flywheel backward. a) Remove plug (5) from the flywheel housing and the breather from the valve cover.b) Turn the flywheel counterclockwise until a 3/8"-16 NC bolt (6) at least 2.5 in. long can be installed in the flywheel through the hole in