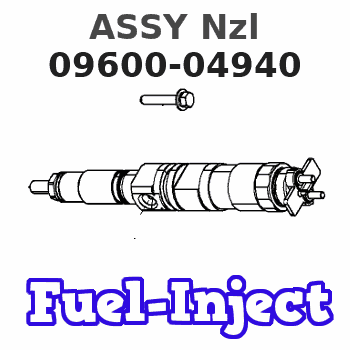

Information assy nzl

Nozzle:

0935004180

Rating:

KIT List:

| Pump assy, injecti | 0960100021 0960100541 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 22100-54860 Compatible with 3L Hilux Hiace 2.8L Engine 2210054860 096000-4940

GHEHCUT Fuel Injection Pump 22100-54860 Compatible with 3L Hilux Hiace 2.8L Engine 2210054860 096000-4940 || The car fuel injection pump is easy to install and suitable for various types of engines || The common rail fuel system enhances the engine's power and overall efficiency || The fuel injection process reduces mechanical noise and combustion noise, enhancing the comfort of driving and riding || The fuel injection pump can still maintain stable fuel injection in a low-temperature environment, enabling the engine to start smoothly

GHEHCUT Fuel Injection Pump 22100-54860 Compatible with 3L Hilux Hiace 2.8L Engine 2210054860 096000-4940 || The car fuel injection pump is easy to install and suitable for various types of engines || The common rail fuel system enhances the engine's power and overall efficiency || The fuel injection process reduces mechanical noise and combustion noise, enhancing the comfort of driving and riding || The fuel injection pump can still maintain stable fuel injection in a low-temperature environment, enabling the engine to start smoothly

You can express buy:

USD 406.7

13-05-2025

13-05-2025

Brand new Fuel Injection Pump FOR TO-YOTA HILUX LN86 166 LNLAND CRUISER LJ95 3L engine fuel pump OEM 22100-54860 096000-4940

USD 638.28

19-05-2025

19-05-2025

New arrival Car Parts Hiace 3L VE Rotary Pump 096000-4940 Fuel Pumps 3L Injector Pump VE410F2050RND494

Components :

| 001. | PUMP ASSY, INJECTI | 09600-04940 |

| 002. | RING SUB-ASSY, ROL | 09618-00020 |

| 003. | GOVERNOR ASSY, TOR | 09627-00060 |

| 004. | SHIM, PLUNGER ADJU | 09640-60020 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09600-04940 | ASSY Nzl | ||

| 22100-54860 | TOYOTA | PUMP ASSY, INJECTI |

Information:

2. Disconnect the fuel lines from fuel transfer pump (1).3. Remove two bolts (2) and fuel transfer pump (1). 4. Be sure O-ring seal (3) is in position on the fuel transfer pump and put clean oil on the O-ring seal.5. Put the fuel transfer pump in position on the fuel injection pump and install the two bolts that hold it in place.6. Connect the fuel lines to the fuel transfer pump.7. Open the fuel shutoff valve at the fuel tank.Disassemble Fuel Transfer Pump

start by:a) remove fuel transfer pump

Cover (2) is under spring tension.

1. Carefully remove bolts (1) and cover (2) from the fuel transfer pump. 2. Remove spring (3), valve (4) and O-ring seals (5) from the cover. 3. Remove springs (6) and (7) from the pump housing. 4. Remove sleeve (8) from the pump housing. 5. Remove sleeve (12), piston (16), O-ring seal (11) and piston (9) from sleeve (8). Remove plate (15), valve (10) and seal (14) from piston (9). Remove O-ring seal (13) from sleeve (8). 6. Remove O-ring seal (17) from the pump housing. 7. Push guide (18) through the pump housing and remove guides (23) and (18) together. Remove rod (20), guide (23), O-ring seal (19) and tappet (21) from guide (18). Remove ring (22) from tappet (21). 8. Remove connector (24), valve (26) and seal (25) from the pump housing. 9. Remove plug (30), spring (28), valve (29) and seal (27) from the pump housing.Assemble Fuel Transfer Pump

1. Clean all parts and be sure all passage are open. 2. Be sure the O-ring seal is in position on plug (4) and put 4L7464 Silicone Grease on the O-ring seal. Valves (2 and 6) must be installed as shown for the pump to work correctly.3. Install seal (1), valve (2), spring (3) and plug (4) in the pump housing as shown. Tighten plug (4) to a torque of 20 7 N m (15 5 lb.ft.). 4. Be sure the O-ring seal is in position on connector (7) and put 4L7464 Silicone Grease on the O-ring seal.5. Install seal (5), valve (6) and connector (7) in the pump housing as shown. Tighten connector (7) to a torque of 55 10 N m (40 7 lb.ft.). 6. Install the ring on tappet (8). Install tappet (8), O-ring seal (12), guide (9) and rod (10) in guide (11). Put 4L7464 Silicone Grease on O-ring seal (12). Install guides (11) and (9) as a unit in the pump housing as shown. 7. Install O-ring seal (13) in the pump housing and put 4L7464 Silicone Grease on the O-ring seal. 8. Install seal (15), valve (19) and plate (16) in piston (14) as shown. Install piston (14), O-ring seal (17), piston (20) and guide (21) in guide (18) as shown. Install the O-ring seal on guide (18) and put 4L7464 Silicone Grease on O-ring seal (17) and the O-ring seal on guide (18). 9. Install guide (18) in the pump housing as shown.

start by:a) remove fuel transfer pump

Cover (2) is under spring tension.

1. Carefully remove bolts (1) and cover (2) from the fuel transfer pump. 2. Remove spring (3), valve (4) and O-ring seals (5) from the cover. 3. Remove springs (6) and (7) from the pump housing. 4. Remove sleeve (8) from the pump housing. 5. Remove sleeve (12), piston (16), O-ring seal (11) and piston (9) from sleeve (8). Remove plate (15), valve (10) and seal (14) from piston (9). Remove O-ring seal (13) from sleeve (8). 6. Remove O-ring seal (17) from the pump housing. 7. Push guide (18) through the pump housing and remove guides (23) and (18) together. Remove rod (20), guide (23), O-ring seal (19) and tappet (21) from guide (18). Remove ring (22) from tappet (21). 8. Remove connector (24), valve (26) and seal (25) from the pump housing. 9. Remove plug (30), spring (28), valve (29) and seal (27) from the pump housing.Assemble Fuel Transfer Pump

1. Clean all parts and be sure all passage are open. 2. Be sure the O-ring seal is in position on plug (4) and put 4L7464 Silicone Grease on the O-ring seal. Valves (2 and 6) must be installed as shown for the pump to work correctly.3. Install seal (1), valve (2), spring (3) and plug (4) in the pump housing as shown. Tighten plug (4) to a torque of 20 7 N m (15 5 lb.ft.). 4. Be sure the O-ring seal is in position on connector (7) and put 4L7464 Silicone Grease on the O-ring seal.5. Install seal (5), valve (6) and connector (7) in the pump housing as shown. Tighten connector (7) to a torque of 55 10 N m (40 7 lb.ft.). 6. Install the ring on tappet (8). Install tappet (8), O-ring seal (12), guide (9) and rod (10) in guide (11). Put 4L7464 Silicone Grease on O-ring seal (12). Install guides (11) and (9) as a unit in the pump housing as shown. 7. Install O-ring seal (13) in the pump housing and put 4L7464 Silicone Grease on the O-ring seal. 8. Install seal (15), valve (19) and plate (16) in piston (14) as shown. Install piston (14), O-ring seal (17), piston (20) and guide (21) in guide (18) as shown. Install the O-ring seal on guide (18) and put 4L7464 Silicone Grease on O-ring seal (17) and the O-ring seal on guide (18). 9. Install guide (18) in the pump housing as shown.