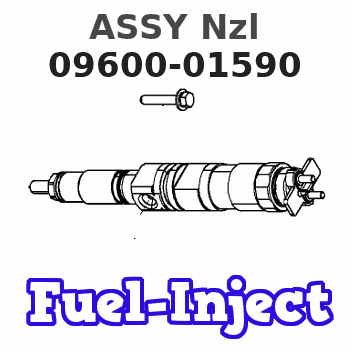

Information assy nzl

Nozzle:

0935002620

Rating:

KIT List:

| Pump assy, injecti | 0960100021 0960100541 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09600-01590 | ASSY Nzl | ||

| MD070721 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Add coolant slowly to a hot engine to prevent possible cracking or distorting the cylinder head.

Most commercial antifreeze solutions contain rust inhibitors, however, it is recommended the adding of Caterpillar Coolant System Inhibitor to glycol base antifreeze if protection is for temperatures above -20°F (-29°C). If protection is for temperatures -20°F (-29°C) or below, do not add inhibitor. Follow instructions given on the container.

Inhibitor contains alkali. Avoid contact with eyes. Avoid prolonged or repeated contact with skin.

If a loss of coolant is noticeable, check for leaks in the system. After filling the system, start the engine and recheck the coolant level after normal operating temperature is reached. Running the engine at operating temperature will permit the thermostat to open and allow the coolant to circulate through the entire system and purge air from the engine.CLEANING THE RADIATOR: Every 10,000 miles clean dirt and trash from between the tubes of the radiator which may cause excessively high operating temperature. Wash, brush or blow the dirt out with whichever method is available and most effective.CLEANING THE COOLING SYSTEM: Clean the cooling system periodically. Mineral deposits can cause serious engine damage by retarding the transfer of heat to the coolant. A deposit of lime 1/32 inch thick insulates the same amount as 2 inches of steel, reducing the heat transfer substantially. Loose scale and sediment deposited in the cooling system will reduce circulation, resulting in possible engine damage. To clean, stop the engine when it is at normal operating temperature and drain as quickly as possible. Flush thoroughly, then fill with a solution of one pound of Oxalic Acid or Sodium Bisulfate per five gallons of water. Run the engine at operating temperature one-half to one hour, then drain and flush until water is clear. Fill with a solution of one-half pound of Sal Soda per ten gallons of water and run the engine ten minutes. Drain, flush and fill with water, adding corrosion inhibitor or the desired amount of anti-freeze.DRAINING: The cooling system is drained by removing the radiator cap, opening the valve in the bottom of the radiator, removing the drain plugs from the water pump and from the left side of the diesel engine block.FILLING THE COOLING SYSTEM: When filling a cooling system it is essential for the system to be filled completely and air pockets elimi-Proper filling procedure is necessary to assure the cooling system is completely filled. Follow the four step recommended procedure.1. Fill the radiator without interrupting the flow of fill water.2. Start the engine.3. Complete filling with the engine running at low idle. It is important this filling be completed as quickly as possible after engine start-up.4. Before installing the radiator cap allow the engine to run at low idle for several minutes then add coolant as necessary. Warm coolant circulating in the top tank is a good indication the system is full. Make sure the system is bled of air and refilled with coolant after a short period of operation. Normally the air