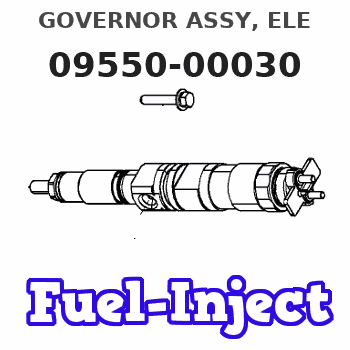

Information governor assy, ele

Rating:

Scheme ###:

| 000. | [01] | 09550-00030 | GOVERNOR ASSY, ELE | |

| 001. | [01] | 09551-00030 | HOUSING SUB-ASSY, | |

| 002. | [01] | 09082-30240 | GASKET | 22847-1570A |

| 002. | [01] | 09082-30460 | GASKET | |

| 003. | [01] | 09101-60151 | BUSHING, BEARING | |

| 004. | [01] | 09556-00011 | ARM SUB-ASSY, STOP | |

| 005. | [01] | 09556-30030 | LEVER, STOP | |

| 006. | [01] | 09556-50030 | SPRING, RETURN | |

| 007. | [01] | 90190-08651 | NUT, HEXAGON | 92010-8070A |

| 008. | [01] | 90258-08001 | WASHER, SPRING | 22877-1720A |

| 009. | [1C] | 94901-33760 | WASHER, PLATE, SK | 22881-2350A |

| 009. | [1C] | 94901-33780 | WASHER, PLATE, SK | 22881-2370A |

| 009. | [1C] | 94901-33790 | WASHER, PLATE, SK | 22881-2380A |

| 010. | [01] | 90801-10080 | O-RING | |

| 011. | [03] | 09552-40010 | SLIDER | |

| 012. | [02] | 09089-40070 | E-RING | 22456-1130A |

| 013. | [01] | 09553-00011 | LEVER SUB-ASSY, CO | |

| 014. | [01] | 91578-06161 | BOLT, W/WASHER | |

| 015. | [01] | 90804-20140 | O-RING | |

| 016. | [01] | 09554-00010 | LEVER SUB-ASSY, CO | |

| 017. | [01] | 90577-06000 | E-RING | |

| 018. | [01] | 09553-90010 | COVER | |

| 019. | [01] | 09554-30021 | JOINT SUB-ASSY | |

| 020. | [01] | 09556-50010 | SPRING, RETURN | |

| 021. | [01] | 09555-10020 | BUSHING, CAMSHAFT | |

| 022. | [01] | 09555-30020 | GEAR | |

| 023. | [01] | 90258-12001 | WASHER, SPRING | 22873-1310A |

| 024. | [01] | 90190-12101 | NUT, HEXAGON | |

| 025. | [3C] | 94901-34230 | WASHER, PLATE, SK | 22885-1620 |

| 025. | [3C] | 94901-34240 | WASHER, PLATE, SK | 22885-1630 |

| 026. | [01] | 09557-00021 | HOUSING SUB-ASSY, | |

| 027. | [01] | 09557-40010 | GASKET | |

| 028. | [01] | 13890-00022 | SOLENOID ASSY, RAC | |

| 029. | [01] | 90804-20670 | O-RING | |

| 030. | [01] | 90804-20350 | O-RING | |

| 031. | [02] | 09559-40010 | BRACKET | |

| 032. | [02] | 91518-06161 | BOLT, W/WASHER | 22815-1310A |

| 033. | [02] | 09140-30100 | WASHER, LOCK | 22877-1210A |

| 034. | [01] | 13650-00084 | SENSOR ASSY, POSIT | |

| 035. | [09] | 91518-05141 | BOLT, W/WASHER | |

| 036. | [01] | 94990-01782 | IC, HYBRID | |

| 037. | [03] | 91518-05201 | BOLT, W/WASHER | |

| 038. | [01] | 94935-06110 | CLIP, CORD | |

| 039. | [01] | 94982-10400 | BAND | |

| 040. | [01] | 94935-06130 | CLIP, CORD | |

| 041. | [01] | 07630-00460 | PICKUP ASSY, TACHO | |

| 042. | [01] | 90804-20210 | O-RING | |

| 043. | [01] | 09558-00022 | CONNECTOR SUB-ASSY | |

| 044. | [01] | 09557-40030 | GASKET | |

| 048. | [01] | 09559-00021 | COVER SUB-ASSY, GO | |

| 049. | [01] | 09557-40040 | GASKET | |

| 050. | [01] | 09553-90020 | COVER | |

| 051. | [01] | 90804-40340 | O-RING | |

| 052. | [01] | 09116-70031 | PLUG, SCREW | 22845-1320A |

| 053. | [01] | 09022-20060 | WASHER, FUEL PIPE | 6 366 1331 10 |

| 054. | [01] | 09559-40070 | BRACKET | |

| 055. | [01] | 09039-10011 | CLIP, CORD | 22131-1231A |

| 056. | [01] | 91518-05081 | BOLT, W/WASHER | 22815-2980A |

| 057. | [06] | 90108-06651 | BOLT, HEXAGON | |

| 058. | [06] | 90258-06001 | WASHER, SPRING | 28219-1110A |

| 059. | [03] | 91418-06161 | BOLT, W/WASHER | 22815-1380A |

| 060. | [01] | 09552-00030 | ARM SUB-ASSY | |

| 061. | [01] | 09552-30070 | PIN | |

| 062. | [01] | 94905-03540 | NUT, HEXAGON | 22825-2010A |

| 063. | [01] | 90258-05001 | WASHER, SPRING | 22873-1380A |

| 064. | [01] | 09558-30030 | GROMMET |

Include in #3:

09550-00030

as GOVERNOR ASSY, ELE

Cross reference number

| Part num | Firm num | Firm | Name |

| 09550-00030 | GOVERNOR ASSY, ELE |

Information:

General Coolant Information

Many engine failures are related to the cooling system. Problems such as overheating, water pump leaking, plugged radiators, and cylinder liner pitting can be avoided with proper cooling system maintenance. Cooling system maintenance is as important as fuel and lubricating system maintenance. Coolant quality is as important as the quality of fuel and lubricating oil.Coolant is normally composed of three elements: * Water* Additives* GlycolWater

Never use water alone without Supplemental Coolant Additives (SCA) or without inhibited coolant. Water alone is corrosive at engine operating temperatures. Water alone does not provide adequate freeze or boil protection.

Distilled or deionized water is recommended for use in engine cooling systems. DO NOT use hard tap water or salt softened tap water in engine cooling systems. If distilled or deionized water is not available, use water that meets the minimum acceptable requirements listed in the following chart. Contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory for water analysis.Additives

Additives must be added to all coolant mixtures. Additives help prevent the formation of rust, scale, and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This can be done by treating conventional coolants with Supplemental Coolant Additives (SCA) or by treating Extended Life Coolant (ELC) with Extender.Additives must be added at the proper concentration. Overconcentration of additives can cause the inhibitors to drop out of the solution and form a gel in the radiator. An overconcentration of additives produces excessive deposits on water pump seals that can cause the water pump seal to leak. Underconcentration of additives can produce pitting, cavitation, erosion, rust, scale, and foaming.Glycol

Glycol in the coolant provides boil and freeze protection, prevents water pump cavitation, and reduces cylinder liner pitting. 50/50 For optimum performance, Caterpillar recommends a glycol/water coolant mixture.Ethylene glycol is used in most conventional heavy duty (HD) coolant/antifreezes. However, propylene glycol may also be used. Both ethylene glycol and propylene glycol have similar fluid properties in a 50/50glycol/water mixture. Both ethylene glycol and propylene glycol provide similar heat transfer, freeze protection, corrosion control, and seal compatibility. The following charts define the temperature protection provided by the two types of glycol.

Do not use propylene glycol in concentrations that exceed 50 percent glycol because of propylene glycol's reduced heat transfer capability. Use ethylene glycol in conditions that require additional boil or freeze protection.

Caterpillar recommends the use of a refractometer for checking the glycol concentration. Use the 1U-7298 Coolant Tester (°C) or use the 1U-7297 Coolant Tester (°F). The testers give immediate, accurate readings and can be used with ethylene or propylene glycol.Coolant Recommendations

DO NOT use a commercial coolant/antifreeze that ONLY meets the ASTM D3306 or D4656 specification. This type of coolant/antifreeze is made for light duty automotive applications.

The primary types of coolant used in Caterpillar commercial diesel engines are: * Preferred - Caterpillar Extended Life Coolant (ELC), or... a commercial ELC meeting the Caterpillar EC-1 specification* Acceptable - Caterpillar

Many engine failures are related to the cooling system. Problems such as overheating, water pump leaking, plugged radiators, and cylinder liner pitting can be avoided with proper cooling system maintenance. Cooling system maintenance is as important as fuel and lubricating system maintenance. Coolant quality is as important as the quality of fuel and lubricating oil.Coolant is normally composed of three elements: * Water* Additives* GlycolWater

Never use water alone without Supplemental Coolant Additives (SCA) or without inhibited coolant. Water alone is corrosive at engine operating temperatures. Water alone does not provide adequate freeze or boil protection.

Distilled or deionized water is recommended for use in engine cooling systems. DO NOT use hard tap water or salt softened tap water in engine cooling systems. If distilled or deionized water is not available, use water that meets the minimum acceptable requirements listed in the following chart. Contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory for water analysis.Additives

Additives must be added to all coolant mixtures. Additives help prevent the formation of rust, scale, and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This can be done by treating conventional coolants with Supplemental Coolant Additives (SCA) or by treating Extended Life Coolant (ELC) with Extender.Additives must be added at the proper concentration. Overconcentration of additives can cause the inhibitors to drop out of the solution and form a gel in the radiator. An overconcentration of additives produces excessive deposits on water pump seals that can cause the water pump seal to leak. Underconcentration of additives can produce pitting, cavitation, erosion, rust, scale, and foaming.Glycol

Glycol in the coolant provides boil and freeze protection, prevents water pump cavitation, and reduces cylinder liner pitting. 50/50 For optimum performance, Caterpillar recommends a glycol/water coolant mixture.Ethylene glycol is used in most conventional heavy duty (HD) coolant/antifreezes. However, propylene glycol may also be used. Both ethylene glycol and propylene glycol have similar fluid properties in a 50/50glycol/water mixture. Both ethylene glycol and propylene glycol provide similar heat transfer, freeze protection, corrosion control, and seal compatibility. The following charts define the temperature protection provided by the two types of glycol.

Do not use propylene glycol in concentrations that exceed 50 percent glycol because of propylene glycol's reduced heat transfer capability. Use ethylene glycol in conditions that require additional boil or freeze protection.

Caterpillar recommends the use of a refractometer for checking the glycol concentration. Use the 1U-7298 Coolant Tester (°C) or use the 1U-7297 Coolant Tester (°F). The testers give immediate, accurate readings and can be used with ethylene or propylene glycol.Coolant Recommendations

DO NOT use a commercial coolant/antifreeze that ONLY meets the ASTM D3306 or D4656 specification. This type of coolant/antifreeze is made for light duty automotive applications.

The primary types of coolant used in Caterpillar commercial diesel engines are: * Preferred - Caterpillar Extended Life Coolant (ELC), or... a commercial ELC meeting the Caterpillar EC-1 specification* Acceptable - Caterpillar