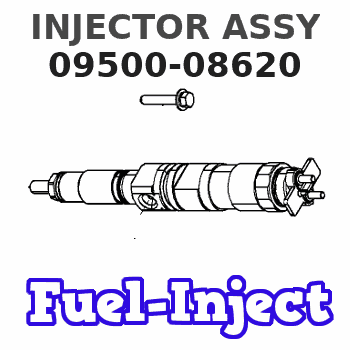

Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

1PCS DLLA145P875 Common Rail Crude Oil Fuel Injector Nozzle For 093400-8750 095000-5760 095000-8110 095000-8620 Injector

ZFBBM High precision: able to control the time, pressure, and quantity of fuel injection with extremely high precision, ensuring the accuracy and consistency of fuel injection. || Adjustability: the fuel injector can adjust the flow rate and injection angle of liquid materials as needed to achieve the best effect. || Excellent: Our tools are made of excellent steel with high hardness, high stability and high strength, exceeding OEM standards and helping you save money in the long run. || Fuel-Efficient Injector: High efficient fuel sprays and High Impedance Coil enable fast start up in the cold environments, low fuel consumption, and better performance. || Commodity confidence: Each product has been professionally inspected and professionally packaged to ensure the integrity of the product.

ZFBBM High precision: able to control the time, pressure, and quantity of fuel injection with extremely high precision, ensuring the accuracy and consistency of fuel injection. || Adjustability: the fuel injector can adjust the flow rate and injection angle of liquid materials as needed to achieve the best effect. || Excellent: Our tools are made of excellent steel with high hardness, high stability and high strength, exceeding OEM standards and helping you save money in the long run. || Fuel-Efficient Injector: High efficient fuel sprays and High Impedance Coil enable fast start up in the cold environments, low fuel consumption, and better performance. || Commodity confidence: Each product has been professionally inspected and professionally packaged to ensure the integrity of the product.

1pc DLLA145P875 093400-8750 095000-5760 095000-8110 095000-8620

NYOMSPLOO

NYOMSPLOO

You can express buy:

USD 27.93

19-05-2025

19-05-2025

DLLA145P875 New Common Rail Crude Oil Fuel Injector Nozzle for 093400-8750 095000-5760 095000-8110 095000-8620 Injector

USD 27.93

13-05-2025

13-05-2025

DLLA145P875 New Common Rail Crude Oil Fuel Injector Nozzle for 093400-8750 095000-5760 095000-8110 095000-8620 Injector

Images:

USD 123.49

[19-May-2025]

USD 111.76

[19-May-2025]

USD 27.93

[05-May-2025]

USD 19.99

[05-May-2025]

Components :

| 001. | INJECTOR ASSY | 09500-08620 |

| 001. | INJECTOR ASSY | 09500-08620 |

Scheme ###:

| 000. | [01] | 09500-08620 | INJECTOR ASSY | ME306200 |

| 000. | [01] | 09500-08621 | INJECTOR ASSY | ME307085 |

Include in #3:

09500-08620

as INJECTOR ASSY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-08620 | ME306200 | INJECTOR ASSY | |

| ME306200 | MITSUBISHI | INJECTOR ASSY | |

| ME307085 | MITSUBISHI | INJECTOR ASSY |

Information:

Possible Causes/Corrections

Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Fuel Settings Not CorrectIf the Power Analysis Report indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. Defective Fuel Nozzle(s)Remove the fuel nozzles and test as in the Testing and Adjusting Section of this Service Manual.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections

Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Fuel Injection Timing Not CorrectFollow the procedures in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceInstall the tooling and follow the procedure given in the "Road Test" section. Fuel Settings Not CorrectIf the Road Test indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. Any Further Diagnosis Must Be Done On A Chassis DynamometerIf the fuel settings are correct and the above procedures have been followed without finding the problem a Power Analysis Report (PAR), Level II, must be done on the engine. See Special Instruction, Form Nos. SEHS8025 and SEHS7886 for the correct tools and procedures to use.

Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Fuel Settings Not CorrectIf the Power Analysis Report indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. Defective Fuel Nozzle(s)Remove the fuel nozzles and test as in the Testing and Adjusting Section of this Service Manual.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections

Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Fuel Injection Timing Not CorrectFollow the procedures in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceInstall the tooling and follow the procedure given in the "Road Test" section. Fuel Settings Not CorrectIf the Road Test indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. Any Further Diagnosis Must Be Done On A Chassis DynamometerIf the fuel settings are correct and the above procedures have been followed without finding the problem a Power Analysis Report (PAR), Level II, must be done on the engine. See Special Instruction, Form Nos. SEHS8025 and SEHS7886 for the correct tools and procedures to use.