Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

FICMVLQC By adopting high-precision processing techniques, the dimensions of each component of the fuel injector are ensured to be precise, guaranteeing the accuracy and stability of fuel injection. || It can fully atomize diesel fuel, enabling better mixture of fuel and air, and promoting efficient combustion. || It is usually manufactured with high-strength, high-temperature-resistant and corrosion-resistant alloy materials to ensure long-term stable operation. || It has excellent sealing performance, preventing fuel leakage and ensuring stable fuel injection pressure. || 4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

FICMVLQC By adopting high-precision processing techniques, the dimensions of each component of the fuel injector are ensured to be precise, guaranteeing the accuracy and stability of fuel injection. || It can fully atomize diesel fuel, enabling better mixture of fuel and air, and promoting efficient combustion. || It is usually manufactured with high-strength, high-temperature-resistant and corrosion-resistant alloy materials to ensure long-term stable operation. || It has excellent sealing performance, preventing fuel leakage and ensuring stable fuel injection pressure. || 4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

UCLMCNID Made of high-strength and corrosion-resistant alloy materials to extend the service life. || It can spray fuel in extremely fine particle form, mix it thoroughly with air, achieve efficient combustion, and improve fuel economy. || Adapting to different working conditions, precise fuel injection can be achieved whether idling, accelerating, or driving at high speeds. || High precision manufacturing, utilizing advanced processing techniques to ensure the dimensional accuracy and performance consistency of fuel injectors. || 4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

UCLMCNID Made of high-strength and corrosion-resistant alloy materials to extend the service life. || It can spray fuel in extremely fine particle form, mix it thoroughly with air, achieve efficient combustion, and improve fuel economy. || Adapting to different working conditions, precise fuel injection can be achieved whether idling, accelerating, or driving at high speeds. || High precision manufacturing, utilizing advanced processing techniques to ensure the dimensional accuracy and performance consistency of fuel injectors. || 4PCS DLLA145P864 Fuel Injector Nozzle For 095000-5930 095000-5880 095000-5660 095000-6190 095000-7390 095000-8740 095000-7760

You can express buy:

USD 10.48

06-05-2025

06-05-2025

07# Control Valve 2959000190 Fuel Injection Pump Parts 07# For 09500064100950007761 0950007760 236700L010 236700L070

USD 14.91

09-05-2025

09-05-2025

294705-0270 Solenoid Valve for 095000-8290, 095000-5930, 095000-7760 Fuel Injector China Made New

Images:

USD 29.2

[28-Nov-2022]

USD 13.29

[13-Nov-2022]

USD 17.99

[13-Nov-2022]

USD 92.8

[19-Dec-2024]

Components :

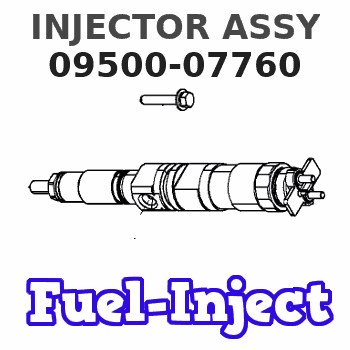

| 001. | INJECTOR ASSY | 09500-07760 |

| 002. | INJECTOR ASSY | 09500-07750 |

Scheme ###:

| 000. | [01] | 09500-07760 | INJECTOR ASSY | 23670-39276 |

| 001. | [01] | 09500-07750 | INJECTOR ASSY | 23670-30300 |

| 002. | [01] | 09313-30830 | GASKET | 11176-30011 |

Include in #3:

09500-07760

as INJECTOR ASSY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-07760 | 23670-3927 | INJECTOR ASSY | |

| 23670-39276 | TOYOTA | INJECTOR ASSY |

Information:

Tightening Procedure For Main Bearings(8) Torque for the bolts that hold the caps for the main bearings: Install the main bearing caps with the marks (arrow) toward the front of the engine. Install each cap in the correct position by putting the number stamped on the bottom of the cap toward the corresponding number cast on left side of the cylinder block at the pan rail.a. Put 2P2506 Thread Lubricant on the threads of the bolts.b. Tighten the bolts first on the bearing tab side of the cap to ... 260 14 N m (190 10 lb ft)c. Tighten the bolts on the opposite side to ... 260 14 N m (190 10 lb ft)d. Put a mark on each bolt and cap.e. Tighten the bolts on the opposite side, from the mark ... 120 5°f. Tighten the bolts on the bearing tab side of the cap, from the mark ... 120 5°(9) Dimension (new) from centerline of crankshaft bearing bore to bottom of block (pan rails) ... 165.10 0.10 mm (6.500 .004 in)

View From Right Side Of Cylinder Block(10) Put 5P3414 Pipe Sealant on threads of plugs before installation in the cylinder block.(11) Torque for bolts holding oil jet cooling tubes ... 30 7 N m (22 5 lb ft) Minimum permissible clearance between piston and oil jet cooling tube ... 0.64 mm (.025 in)