Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

shsiyayh 4X Fuel Injector 33800-87000 3380087000 for Diesel Engine

shsiyayh Part Name:Fuel Injector || Part Number:33800-87000 3380087000 || APPlication: Compatible with Diesel Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:33800-87000 3380087000 || APPlication: Compatible with Diesel Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh 1X Fuel Injector 33800-87000 3380087000 for Diesel Engine

shsiyayh Part Name:Fuel Injector || Part Number:33800-87000 3380087000 || APPlication: Compatible with Diesel Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:33800-87000 3380087000 || APPlication: Compatible with Diesel Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

3380087000 ORIGINAL COMMON RAIL INJECTOR 095000-6030 33800-87000 Compatible for HYHYUNDA 33800 87000(33800-87000)

CDFDKMGP 3380087000 ORIGINAL COMMON RAIL INJECTOR 095000-6030 33800-87000 Compatible for HYHYUNDA 33800 87000 || Reliability:made of high-quality materials,with long service life and high reliability, it can work stably in various harsh environments || Replacement: easy to install, no need for complicated tools, easy to use, directly replace your old or broken parts, and perfectly replace your original parts. || Ideal replacement products: reliable performance, simple installation, accurate design to suit your specific vehicle matching and performance, and thorough inspection. || The fuel injector can be started in cold environment; No modification is required. Reduce fuel consumption: The fuel injector is designed to improve fuel efficiency and reduce the overall fuel consumption of the vehicle.

CDFDKMGP 3380087000 ORIGINAL COMMON RAIL INJECTOR 095000-6030 33800-87000 Compatible for HYHYUNDA 33800 87000 || Reliability:made of high-quality materials,with long service life and high reliability, it can work stably in various harsh environments || Replacement: easy to install, no need for complicated tools, easy to use, directly replace your old or broken parts, and perfectly replace your original parts. || Ideal replacement products: reliable performance, simple installation, accurate design to suit your specific vehicle matching and performance, and thorough inspection. || The fuel injector can be started in cold environment; No modification is required. Reduce fuel consumption: The fuel injector is designed to improve fuel efficiency and reduce the overall fuel consumption of the vehicle.

You can express buy:

USD 52.5

13-11-2022

13-11-2022

ORLTL 4pcs Dlla150p914 Oil Burner Nozzle DLLA150P914 Dlla 150 p 914 Fuel Pump Injection Nozzle for Denso 095000-6030 Accessories

Components :

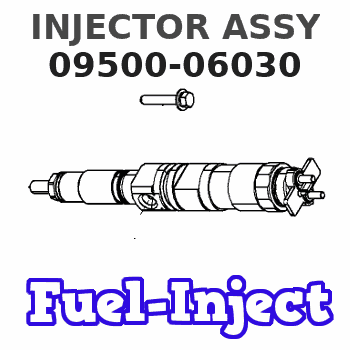

| 001. | INJECTOR ASSY | 09500-06030 |

Include in #3:

09500-06030

as INJECTOR ASSY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-06030 | 3380087000 | INJECTOR ASSY | |

| 3380087000 | HYUNDAI | INJECTOR ASSY |

Information:

Start By:a. disassemble governorb. remove fuel injection pumps

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove cover (1) and gasket. 2. Remove rack (2).

If the original lifters are to be installed in the fuel injection pump housing, put identification marks on them as to their location in the housing.

3. Remove lifters (3). 4. Put the fuel injection pump housing on end on blocks. Use tool (A) to remove snap ring (4). 5. Use a soft hammer to push the camshaft toward the governor end of the fuel injection pump housing to loosen washer (5). Remove washer (5). 6. Remove camshaft (6). 7. Remove bearings (7) from the drive end of the fuel injection pump housing. 8. Remove bearings (8) from the governor end of the fuel injection pump housing.Assemble Fuel Injection Pump Housing

Be sure all oil passages are clear, and put clean oil on all parts before assembly. 1. Use tooling (B) to install bearing (10) in the governor end of the fuel injection pump housing with junction (joint) (11) toward the top of the fuel injection pump housing. Install the bearing so it is 0.25 0.20 mm (0.10 0.008 in) below the surface of the housing.2. Use tooling (B) to install bearing (9) in the governor end of the fuel injection pump housing so it is 7.16 0.13 mm (0.282 0.005 in) below the surface of the housing. 3. Use tooling (B) to install bearing (12) in the drive end of the fuel injection pump housing with the junction (joint) in the bearing toward the top of the fuel injection pump housing. Install the bearing so it is 1.00 0.25 mm (9.039 0.010 in) below the surface of the housing. 4. Install plate (13) of tooling (C) on the drive end of the fuel injection pump housing to install the bearing for the rack. Use clean grease to hold the new rack bearing on driver (14) of tooling (C). Install the driver and bearing in plate (13) with the groove in the driver in alignment with the pin in the plate and use a hammer to push the bearing into position. The bearing will be installed to the correct depth when the shoulder of the driver is against plate (13).5. Remove tooling (C) from the fuel injection pump housing. The rack bearing must be installed so it is 0.25 0.25 mm (0.010 0.010 in) below the surface of the housing. 6. Install camshaft (6).7. Put the fuel injection pump housing on end, and place a block under the camshaft. 8. Put washer (5) over the end of the camshaft and use tooling (B) and a spacer (15) that has an inside diameter of 38.1 mm (1.5 in) and a length of 31.75 mm (1.25 in) to push the washer against its seat on the camshaft. Camshaft must have 0.285 0.235 mm (0.0112 0.0093 in) end play

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove cover (1) and gasket. 2. Remove rack (2).

If the original lifters are to be installed in the fuel injection pump housing, put identification marks on them as to their location in the housing.

3. Remove lifters (3). 4. Put the fuel injection pump housing on end on blocks. Use tool (A) to remove snap ring (4). 5. Use a soft hammer to push the camshaft toward the governor end of the fuel injection pump housing to loosen washer (5). Remove washer (5). 6. Remove camshaft (6). 7. Remove bearings (7) from the drive end of the fuel injection pump housing. 8. Remove bearings (8) from the governor end of the fuel injection pump housing.Assemble Fuel Injection Pump Housing

Be sure all oil passages are clear, and put clean oil on all parts before assembly. 1. Use tooling (B) to install bearing (10) in the governor end of the fuel injection pump housing with junction (joint) (11) toward the top of the fuel injection pump housing. Install the bearing so it is 0.25 0.20 mm (0.10 0.008 in) below the surface of the housing.2. Use tooling (B) to install bearing (9) in the governor end of the fuel injection pump housing so it is 7.16 0.13 mm (0.282 0.005 in) below the surface of the housing. 3. Use tooling (B) to install bearing (12) in the drive end of the fuel injection pump housing with the junction (joint) in the bearing toward the top of the fuel injection pump housing. Install the bearing so it is 1.00 0.25 mm (9.039 0.010 in) below the surface of the housing. 4. Install plate (13) of tooling (C) on the drive end of the fuel injection pump housing to install the bearing for the rack. Use clean grease to hold the new rack bearing on driver (14) of tooling (C). Install the driver and bearing in plate (13) with the groove in the driver in alignment with the pin in the plate and use a hammer to push the bearing into position. The bearing will be installed to the correct depth when the shoulder of the driver is against plate (13).5. Remove tooling (C) from the fuel injection pump housing. The rack bearing must be installed so it is 0.25 0.25 mm (0.010 0.010 in) below the surface of the housing. 6. Install camshaft (6).7. Put the fuel injection pump housing on end, and place a block under the camshaft. 8. Put washer (5) over the end of the camshaft and use tooling (B) and a spacer (15) that has an inside diameter of 38.1 mm (1.5 in) and a length of 31.75 mm (1.25 in) to push the washer against its seat on the camshaft. Camshaft must have 0.285 0.235 mm (0.0112 0.0093 in) end play