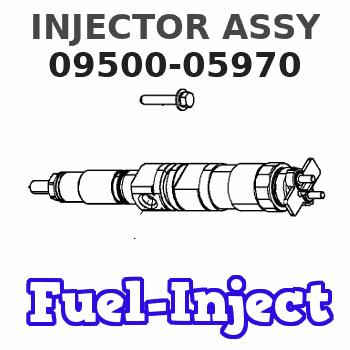

Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

095000-5970 23670-E0360 095000-5971 095000-5972 Common Rail Injector for Hino 700 Series E13C Engine FS SS 6x4

GENERIC Part Number: 23670-E0360 095000-5970 095000-5971 095000-5972 || Application: for Hino 700 Series E13C Engine || Part Name: Engine Diesel Fuel Injector

GENERIC Part Number: 23670-E0360 095000-5970 095000-5971 095000-5972 || Application: for Hino 700 Series E13C Engine || Part Name: Engine Diesel Fuel Injector

Qiape Fuel Injector for Hino Truck 700 Series Diesel Engine P13C E13C 095000-5970 0950005970

Qiape Part Name:Fuel Injector 095000-5970 0950005970 || Part Number:095000-5970 0950005970 || APPlication: Compatible with Hino Truck 700 Series Diesel Engine P13C E13C || Please tell us of your engine model or a view of nameplate when order this item to lower the error rate Thanks || There are no instructions included in this kit it is recommended to install professionally

Qiape Part Name:Fuel Injector 095000-5970 0950005970 || Part Number:095000-5970 0950005970 || APPlication: Compatible with Hino Truck 700 Series Diesel Engine P13C E13C || Please tell us of your engine model or a view of nameplate when order this item to lower the error rate Thanks || There are no instructions included in this kit it is recommended to install professionally

095000-5970 23670-E0360 095000-5971 095000-5972 Common Rail Injector for Hino 700 Series E13C Engine FS SS 6x4

Sgaorcpas Part Number: 23670-E0360 095000-5970 095000-5971 095000-5972 || Application: for Hino 700 Series E13C Engine || Part Name: Engine Diesel Fuel Injector || If you are unsure whether this product is suitable for your machine, please send a message to Sgaorcpas before purchasing and provide detailed information. Sgaorcpas will determine whether it meets your needs ahead of time. || For any questions about the product, including but not limited to pre-sale and after-sale issues, you can contact Sgaorcpas, and we will reply to your email as soon as possible.

Sgaorcpas Part Number: 23670-E0360 095000-5970 095000-5971 095000-5972 || Application: for Hino 700 Series E13C Engine || Part Name: Engine Diesel Fuel Injector || If you are unsure whether this product is suitable for your machine, please send a message to Sgaorcpas before purchasing and provide detailed information. Sgaorcpas will determine whether it meets your needs ahead of time. || For any questions about the product, including but not limited to pre-sale and after-sale issues, you can contact Sgaorcpas, and we will reply to your email as soon as possible.

You can express buy:

USD 40.99

15-07-2022

15-07-2022

23670-E0360 095000-5970 Injector Repair Kits DLLA158P909 Nozzle Tips 10# Control Valve Orifice For HINO

Images:

USD 57.25

[10-Nov-2022]

USD 42.99

[10-Nov-2022]

USD 169

[10-Nov-2022]

USD 168

[06-Feb-2019]

Components :

| 001. | INJECTOR ASSY | 09500-05970 |

| 001. | INJECTOR ASSY | 09500-05970 |

Scheme ###:

| 000. | [01] | 09500-05970 | INJECTOR ASSY | 5-86526251-0 |

| 000. | [01] | 09500-05972 | INJECTOR ASSY | 5-86511859-0 |

Include in #3:

09500-05970

as INJECTOR ASSY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-05970 | 5-86526251 | INJECTOR ASSY | |

| 5-86526251-0 | ISUZU | INJECTOR ASSY | |

| 5-86511859-0 | ISUZU | INJECTOR ASSY | |

| 23910-1380 | HINO | INJECTOR ASSY | |

| 23670-E0360 | HINO | INJECTOR ASSY |

Information:

Caterpillar does not recommend checking actual engine bearing clearances, particularly on small engines, because of the possibility of obtaining inaccurate results, and the possibility of damaging the bearing or journal surfaces. Each Caterpillar engine bearing is quality checked for specific wall thickness. If the crankshaft journals and bores for the block and rods were measured at disassembly and found to be within specifications, no further checks are necessary when using the correct bearings. However, if the serviceman still wants to measure the bearing clearances, Plastigage is an acceptable method. Plastigage is less accurate on small diameter journals where clearances are less than 0.10 mm (0.004 in).

Lead wire, shim stock or a dial bore gauge can damage the bearing surfaces.

1. The serviceman must be very careful to use Plastigage correctly. The following points must be remembered:a. Make sure that the backs of the bearings and the bores are clean and dry.b. Make sure that the bearing locking tabs are properly seated in their slots.c. The crankshaft must be free of oil where the Plastigage touches it.d. If the main bearing clearances are checked with the engine upright or on its side, the crankshaft must be supported. Use a jack under an adjacent crankshaft counterweight and hold the crankshaft against the crown of the bearing. If the crankshaft is not supported, the weight of the crankshaft will cause incorrect readings.3. Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.f. Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.g. Do not turn the crankshaft with the Plastigage installed. h. Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal, See photograph.i. Remove all the Plastigage before reinstalling the cap. When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major width to make sure they are within the specification range.

Lead wire, shim stock or a dial bore gauge can damage the bearing surfaces.

1. The serviceman must be very careful to use Plastigage correctly. The following points must be remembered:a. Make sure that the backs of the bearings and the bores are clean and dry.b. Make sure that the bearing locking tabs are properly seated in their slots.c. The crankshaft must be free of oil where the Plastigage touches it.d. If the main bearing clearances are checked with the engine upright or on its side, the crankshaft must be supported. Use a jack under an adjacent crankshaft counterweight and hold the crankshaft against the crown of the bearing. If the crankshaft is not supported, the weight of the crankshaft will cause incorrect readings.3. Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.f. Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.g. Do not turn the crankshaft with the Plastigage installed. h. Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal, See photograph.i. Remove all the Plastigage before reinstalling the cap. When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major width to make sure they are within the specification range.