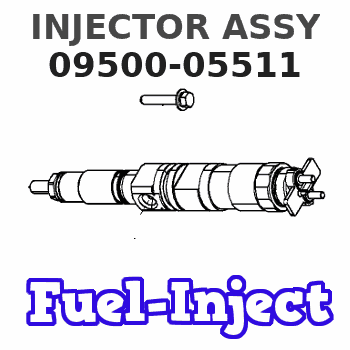

Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Otobaijeni 6PCS 095000-5511 8-97603415-4 Fuel Injector for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L Engine Fuel System, OEM Parts

otobaijeni Part number: 8-97603415-4 8-97603415-2 095000-5511 8976034154 8976034152 0950005511 || Application: Fit for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L || Cost effective and reliable: Trustworthy manufacturing for far less than same part at the dealership || Ideal replacement: Precision-engineered to match the fit and performance on specific vehicles || Ensure fit: To make sure this part fits your exact vehicle.

otobaijeni Part number: 8-97603415-4 8-97603415-2 095000-5511 8976034154 8976034152 0950005511 || Application: Fit for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L || Cost effective and reliable: Trustworthy manufacturing for far less than same part at the dealership || Ideal replacement: Precision-engineered to match the fit and performance on specific vehicles || Ensure fit: To make sure this part fits your exact vehicle.

Otobaijeni 4PCS 095000-5511 8-97603415-4 8-97603415-2 Fuel Injector for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L Engine Fuel System, OEM Parts

otobaijeni Part number: 8-97603415-4 8-97603415-2 095000-5511 8976034154 8976034152 0950005511 || Application: Fit for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L || Cost effective and reliable: Trustworthy manufacturing for far less than same part at the dealership || Ideal replacement: Precision-engineered to match the fit and performance on specific vehicles || Ensure fit: To make sure this part fits your exact vehicle.

otobaijeni Part number: 8-97603415-4 8-97603415-2 095000-5511 8976034154 8976034152 0950005511 || Application: Fit for Isuzu 6WF1 6WG1 6UZ1 Engine N-Series 4HK1 5.2L || Cost effective and reliable: Trustworthy manufacturing for far less than same part at the dealership || Ideal replacement: Precision-engineered to match the fit and performance on specific vehicles || Ensure fit: To make sure this part fits your exact vehicle.

Fuel Injector 8-97603415-2 8-97603415-4 8-97603415-8 095000-5515 095000-5511 095000-5512 for Isuzu N-Series 4HK1 4JJ1

MGHOME Part Number: 8-97603415-2 8-97603415-4 8-97603415-8 095000-5515 095000-5511 095000-5512 || Applicable models: Fit for Isuzu N-Series 4HK1 4JJ1 || Safety: 100% Tested Before Shipping to Ensure Product Safety, Stability and Durability. || Function: High-quality material for long-lasting durability. Perfect match for the original car and easy to install || TIPS: Please be sure to compare carefully with photos and check part number before buying items, If you are not sure this part is suitable, please feel free to contact us, we'll reply you as soon as possible.

MGHOME Part Number: 8-97603415-2 8-97603415-4 8-97603415-8 095000-5515 095000-5511 095000-5512 || Applicable models: Fit for Isuzu N-Series 4HK1 4JJ1 || Safety: 100% Tested Before Shipping to Ensure Product Safety, Stability and Durability. || Function: High-quality material for long-lasting durability. Perfect match for the original car and easy to install || TIPS: Please be sure to compare carefully with photos and check part number before buying items, If you are not sure this part is suitable, please feel free to contact us, we'll reply you as soon as possible.

You can express buy:

USD 316.52

01-07-2023

01-07-2023

Original fuel injector 095000-5511 8-97603415-7 genuine nozzle same as 095000-8981 095000-5516 for 6WG1 CX6WF

Images:

USD 125.9

[13-Nov-2022]

USD 179.9

[07-Oct-2022]

USD 81

[11-Nov-2022]

USD 42.99

[10-Nov-2022]

Components :

| 001. | INJECTOR ASSY | 09500-05511 |

| 001. | INJECTOR ASSY | 09500-05511 |

| 001. | INJECTOR ASSY | 09500-05511 |

| 001. | INJECTOR ASSY | 09500-05511 |

| 001. | INJECTOR ASSY | 09500-05511 |

Scheme ###:

| 000. | [01] | 09500-05511 | INJECTOR ASSY | 8-97603415-1 |

| 000. | [01] | 09500-05511 | INJECTOR ASSY | 8-97603415-2 |

| 000. | [01] | 09500-05512 | INJECTOR ASSY | 8-97603415-3 |

| 000. | [01] | 09500-05513 | INJECTOR ASSY | 8-97603415-4 |

| 000. | [01] | 09500-05514 | INJECTOR ASSY | 8-97603415-5 |

| 000. | [01] | 09500-05515 | INJECTOR ASSY | 8-97603415-6 |

| 000. | [01] | 09500-05516 | INJECTOR ASSY | 8-97603415-7 |

Include in #3:

09500-05511

as INJECTOR ASSY

09500-05511

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-05511 | 8-97603415 | INJECTOR ASSY |

Information:

Start By:

Do not let the tops of the nozzles turn while the fuel lines are loosened. The nozzles will be damaged if the top of the nozzle turns in the body. Defective fuel nozzles will damage the engine due to improper spray patterns.

a. remove fuel injection lines

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove clamp (1). 2. Install tool (A). Move the screw out of the poller enough to engage the inside lip of the puller on the lower stepped diameter of the nozzle.

Do not exceed a torque of 17 N m (13 lb ft) on the screw in tooling (A) to remove the nozzle. Added force can cause the stem of the nozzle to vend or break off.

3. With the nozzle bleed screw seen through the clearance hole in tooling (A), turn the screw down until the tip of the button goes down into the thread in the hole for the nozzle clamp bolt. When tooling (B) is used, the nozzle must be replaced.4. If the nozzle can not be removed with tooling (A), tooling (B) must be used.

Hold tool (B) so the center line of tool (B) is the same as the extended center line of fuel injection nozzle (2). This will prevent distortion of the fuel injection nozzle which can cause the nozzle to bend or break off.

5. Remove the protective cap and install tooling (B).6. Use the slide hammer to remove fuel injection nozzle (2).7. For nozzles removed using tool (A), remove the carbon dam seal on the end of the nozzle. The following steps are for the installation of the fuel injection nozzles. Tool (C) must be modified by drilling it out to a diameter of 8.5 mm (.344 in) and to a depth of 1.5 mm (.060 in) before it can be used on the 8N7002 Fuel Nozzles. 8. Use tool (C) to install carbon dam seal (4).9. To clean the nozzles, see Special Instruction SEHS7292 for the use of tooling (D).10. Install new seal (5). 11. Use tool (D) to clean the bore for the fuel injection nozzle. Use as open end wrench of tap driver to turn tool (E).

Do not let the tops of the fuel nozzles turn when the fuel lines are tightened. The nozzles will be damaged if the top of the nozzle turns in the body.

12. Install fuel injection nozzle (3). Put the nozzle in position with the bleed screw away from the rocker arm cover and install clamp (1).End By:a. install fuel injection lines

Perform Scheduled Oil Sampling after performing service work to check for fuel leakage and contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Do not let the tops of the nozzles turn while the fuel lines are loosened. The nozzles will be damaged if the top of the nozzle turns in the body. Defective fuel nozzles will damage the engine due to improper spray patterns.

a. remove fuel injection lines

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove clamp (1). 2. Install tool (A). Move the screw out of the poller enough to engage the inside lip of the puller on the lower stepped diameter of the nozzle.

Do not exceed a torque of 17 N m (13 lb ft) on the screw in tooling (A) to remove the nozzle. Added force can cause the stem of the nozzle to vend or break off.

3. With the nozzle bleed screw seen through the clearance hole in tooling (A), turn the screw down until the tip of the button goes down into the thread in the hole for the nozzle clamp bolt. When tooling (B) is used, the nozzle must be replaced.4. If the nozzle can not be removed with tooling (A), tooling (B) must be used.

Hold tool (B) so the center line of tool (B) is the same as the extended center line of fuel injection nozzle (2). This will prevent distortion of the fuel injection nozzle which can cause the nozzle to bend or break off.

5. Remove the protective cap and install tooling (B).6. Use the slide hammer to remove fuel injection nozzle (2).7. For nozzles removed using tool (A), remove the carbon dam seal on the end of the nozzle. The following steps are for the installation of the fuel injection nozzles. Tool (C) must be modified by drilling it out to a diameter of 8.5 mm (.344 in) and to a depth of 1.5 mm (.060 in) before it can be used on the 8N7002 Fuel Nozzles. 8. Use tool (C) to install carbon dam seal (4).9. To clean the nozzles, see Special Instruction SEHS7292 for the use of tooling (D).10. Install new seal (5). 11. Use tool (D) to clean the bore for the fuel injection nozzle. Use as open end wrench of tap driver to turn tool (E).

Do not let the tops of the fuel nozzles turn when the fuel lines are tightened. The nozzles will be damaged if the top of the nozzle turns in the body.

12. Install fuel injection nozzle (3). Put the nozzle in position with the bleed screw away from the rocker arm cover and install clamp (1).End By:a. install fuel injection lines

Perform Scheduled Oil Sampling after performing service work to check for fuel leakage and contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.