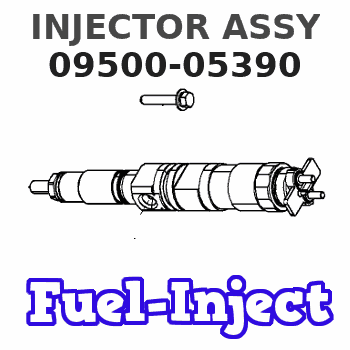

Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$427.50

19 Dec 2024

0.1102[0.05] pounds

CN: zg0565419870zhan

Fuel Injector Nozzle Common Rail Fuel Injector 095000-5390, 095000-5391, 095000-5392, 095000-5393, 095000-5394 Compatible For 23670-E0270 23670-E0271 Diesel Fuel Injector.

facaila Fuel Injector Nozzle Common Rail Fuel Injector 095000-5390, 095000-5391, 095000-5392, 095000-5393, 095000-5394 Compatible For 23670-E0270 23670-E0271 Diesel Fuel Injector. || ℝ Orbital diesel fuel injector: the diesel fuel injector adopts advanced technology, which improves the combustion efficiency of the diesel engine and ensures that the engine runs more efficiently. || ℝ Engine Fuel Injector: the injector nozzle undergoes a precision machining process to ensure accurate and stable fuel injection, which improves engine performance and reduces fuel waste. || ℝ Injector kit: this fuel injector is manufactured with high-quality materials with durability and reliability, capable of running stably under various working conditions, prolonging the service life of the engine and ensuring its normal operation. || ℝ FUEL SYSTEM COMPONENTS: The fine nozzle design of the diesel module injector achieves effective atomization of the fuel, ensuring that every drop of fuel fully enters the engine combustion chamber, optimizing the engine's working efficiency. Injector nozzles This optimized fuel injection system keeps the engine in good working condition and provides efficient and reliable power output.

facaila Fuel Injector Nozzle Common Rail Fuel Injector 095000-5390, 095000-5391, 095000-5392, 095000-5393, 095000-5394 Compatible For 23670-E0270 23670-E0271 Diesel Fuel Injector. || ℝ Orbital diesel fuel injector: the diesel fuel injector adopts advanced technology, which improves the combustion efficiency of the diesel engine and ensures that the engine runs more efficiently. || ℝ Engine Fuel Injector: the injector nozzle undergoes a precision machining process to ensure accurate and stable fuel injection, which improves engine performance and reduces fuel waste. || ℝ Injector kit: this fuel injector is manufactured with high-quality materials with durability and reliability, capable of running stably under various working conditions, prolonging the service life of the engine and ensuring its normal operation. || ℝ FUEL SYSTEM COMPONENTS: The fine nozzle design of the diesel module injector achieves effective atomization of the fuel, ensuring that every drop of fuel fully enters the engine combustion chamber, optimizing the engine's working efficiency. Injector nozzles This optimized fuel injection system keeps the engine in good working condition and provides efficient and reliable power output.

$51.21

19 Nov 2024

KR: Adabus

Del phi Brand ! Fuel Nozzle DLLA155P848 6980525 for Injector 095000-6353/635# 095000-5390 095000-5394 23670-E0050 23910-1440

Generic

Generic

$241.10

18 Sep 2024

0.1102[0.05] pounds

CN: GOGOSHOP01

095000-5390 23670-E0270 095000-5394 Diesel Fuel Injector 095000-5391,Compatible For DENSO Hino Engine J05C J05D 23670-E0271

LUVCAASXQ Precise injection: Diesel Fuel Injector can achieve accurate fuel injection, ensuring that the amount and time of each injection is just right, to improve combustion efficiency || Precise atomization: Diesel Injector Assembly can produce extremely fine fuel particles to ensure that fuel and air are fully mixed to achieve efficient combustion || Durability: The high quality materials and precision process used in the Fuel injector Assembly can withstand long periods of high temperature, high pressure and frequent working cycles || Energy saving and high efficiency: Common Rail Injector Assembly reduces fuel waste and improves fuel utilization by optimizing the injection process, thus saving fuel costs for users || 095000-5390 23670-E0270 095000-5394 Diesel Fuel Injector 095000-5391 ,Compatible For DENSO Hino Engine J05C J05D 23670-E0271

LUVCAASXQ Precise injection: Diesel Fuel Injector can achieve accurate fuel injection, ensuring that the amount and time of each injection is just right, to improve combustion efficiency || Precise atomization: Diesel Injector Assembly can produce extremely fine fuel particles to ensure that fuel and air are fully mixed to achieve efficient combustion || Durability: The high quality materials and precision process used in the Fuel injector Assembly can withstand long periods of high temperature, high pressure and frequent working cycles || Energy saving and high efficiency: Common Rail Injector Assembly reduces fuel waste and improves fuel utilization by optimizing the injection process, thus saving fuel costs for users || 095000-5390 23670-E0270 095000-5394 Diesel Fuel Injector 095000-5391 ,Compatible For DENSO Hino Engine J05C J05D 23670-E0271

You can express buy:

USD 658.94

23-06-2025

23-06-2025

6PCS 095000-5390 23670-E0270 Common Rail Injector 095000-5394 Diesel Engine Nozzle for Hino J05C J05D 3670-E0271 095000-5391

USD 109.99

14-06-2025

14-06-2025

095000-5390 095000-5391 095000-5392 Diesel Fuel Injector for Hino J05C J05D 23670-E0270 23670-E0271 23910-1310 23670-78060

Images:

USD 168

[13-May-2025]

USD 438.96

[13-May-2025]

USD 107.9

[13-May-2025]

USD 107.9

[13-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-05390 | 16650Z5000 | INJECTOR ASSY | |

| 23910-1310 | HINO | INJECTOR ASSY | |

| 23670-E0271 | HINO | INJECTOR ASSY | |

| 23670-E0270 | HINO | INJECTOR ASSY | |

| 23670-78061 | TOYOTA | INJECTOR ASSY | |

| 23670-78060 | TOYOTA | INJECTOR ASSY | |

| 16650Z502E | UD TRUCKS | INJECTOR ASSY | |

| 16650Z501B | UD TRUCKS | INJECTOR ASSY | |

| 16650Z5000 | UD TRUCKS | INJECTOR ASSY |

Information:

1. Remove oil supply tube (1) and suction bell and tube (2). 2. Remove bolts (3) that hold the oil pump to the cylinder block and remove oil pump (4).3. To install, put oil pump (4) in position on the cylinder block. Install the bolts that hold the oil pump to the cylinder block.4. Put clean engine oil on the O-ring seals of the tubes.5. Install oil supply tube (1), suction bell and tube (2).End By:a. install oil panDisassemble Oil Pump

Start By:a. remove oil pump 1. Remove the bolt and washer that hold the gear on the shaft.2. Use Tool (A) and remove drive gear (1) from the shaft. Remove the key from the shaft. 3. Remove retainer (3) for the bypass valve. Remove the spring and the bypass valve.4. Remove cover (2) from the pump body. 5. Use Tool (B) and remove the bearings from the cover. 6. Remove gears (5) from pump body (4).7. Use Tool (B) and remove the bearings from pump body (4).Assemble Oil Pump

1. Use Tool (B) to install the bearings in the pump body. Install the bearings so the joint in the bearings is 30 15 degrees from the center line of the oil pump outlet passage (2). 2. Install idler gear and drive gear (5) in the oil pump body (4). Put clean engine oil on the bearings and the gears. 3. Use Tool (A) and install the bearings in cover (2). Install the bearings so the joint of the bearing bores toward oil pump outlet passage (6).4. Install bypass valve (7), spring (8) and the retainer.5. Install the key on the shaft. 6. Install gear (1) on the shaft. Install the washer and bolt that hold the gear on the shaft. Be sure the pump turns freely after assembly.End By:a. install oil pump

Start By:a. remove oil pump 1. Remove the bolt and washer that hold the gear on the shaft.2. Use Tool (A) and remove drive gear (1) from the shaft. Remove the key from the shaft. 3. Remove retainer (3) for the bypass valve. Remove the spring and the bypass valve.4. Remove cover (2) from the pump body. 5. Use Tool (B) and remove the bearings from the cover. 6. Remove gears (5) from pump body (4).7. Use Tool (B) and remove the bearings from pump body (4).Assemble Oil Pump

1. Use Tool (B) to install the bearings in the pump body. Install the bearings so the joint in the bearings is 30 15 degrees from the center line of the oil pump outlet passage (2). 2. Install idler gear and drive gear (5) in the oil pump body (4). Put clean engine oil on the bearings and the gears. 3. Use Tool (A) and install the bearings in cover (2). Install the bearings so the joint of the bearing bores toward oil pump outlet passage (6).4. Install bypass valve (7), spring (8) and the retainer.5. Install the key on the shaft. 6. Install gear (1) on the shaft. Install the washer and bolt that hold the gear on the shaft. Be sure the pump turns freely after assembly.End By:a. install oil pump