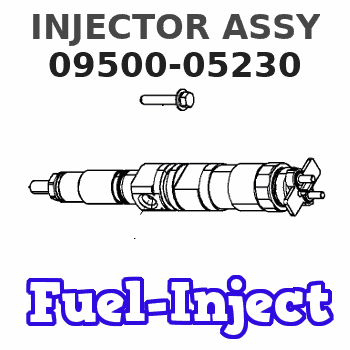

Information injector assy

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

IMIFAFTAbT 095000-5230 6 PCS Fuel injector Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder

IMIFAFTAbT Product Name: 095000-5230 Fuel injector || Part number: 095000-5230 || Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder || 6 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 095000-5230 Fuel injector || Part number: 095000-5230 || Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder || 6 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT 095000-5230 1 PCS Fuel injector Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder

IMIFAFTAbT Product Name: 095000-5230 Fuel injector || Part number: 095000-5230 || Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder || 1 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 095000-5230 Fuel injector || Part number: 095000-5230 || Fits for John Deere 6081 6081HT Engine 608B Harvester 750J 850J Dozer 1710D Forwarder || 1 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

Fuel Injector 095000-5230 RE524360 for John Deere Engine 6081T 6PCS

KoovDem Part Number: 095000-5230 RE524360 || Part Name:Fuel Injectors || Quality Assurance: Each injector undergoes factory testing for flow rate, pressure retention and leak prevention || Compatibility Guarantee: Matches original equipment specifications for seamless performance integration || Please verify your required part number before ordering. You may also provide your vehicle details for our compatibility verification service.

KoovDem Part Number: 095000-5230 RE524360 || Part Name:Fuel Injectors || Quality Assurance: Each injector undergoes factory testing for flow rate, pressure retention and leak prevention || Compatibility Guarantee: Matches original equipment specifications for seamless performance integration || Please verify your required part number before ordering. You may also provide your vehicle details for our compatibility verification service.

You can express buy:

USD 124.16

14-06-2025

14-06-2025

For John Deere 6081 8.1D RE524360 095000-5230 6x Fuel Injector Nozzle DLLA148P828 093400-8280

USD 109.99

19-05-2025

19-05-2025

095000-5230 Car Engine Fuel Injector RE518727 RE524360 Injector Diesel SE501935 AP50802 AP50902 for John Deere Various

Images:

USD 658.94

[13-May-2025]

USD 658.94

[13-May-2025]

USD 78.96

[13-May-2025]

USD 1.5

[13-May-2025]

Components :

| 001. | INJECTOR ASSY | 09500-05230 |

Include in #3:

09500-05230

as INJECTOR ASSY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09500-05230 | RE518727 | INJECTOR ASSY | |

| RE518727 | JOHN DEERE | INJECTOR ASSY |

Information:

Owner/Operator Input

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. THERE ARE NO HARD AND FAST ANSWERS FOR THESE QUESTIONS. There are many different truck engine specifications and truck vehicle specifications which will provide acceptable results. There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly.1. Is there a particular operating condition when the complaint occurs? Low power and response complaints require different repairs. Complaints during shifting will be different from complaints of low power in certain speed ranges or in certain terrains.2. What are the customer's expectations for fuel mileage and power and why does he have those expectations? Comparisons to other trucks on the road often have many unseen variables. If comparison to others is the basis for the complaint, you must insure that the comparison is valid.3. What are the normal upshift and downshift rpm's? If the shift points are too high, find out why. If the driver is operating this way out of habit or because he is taught to drive that way, arrange for him to receive the Caterpillar driver training information. If his shift points are too high because of poor performance, you may be able to correct this in the engine.4. What are the normal routes and loads for the truck? You should be looking for the amount of city versus highway driving, versus mountainous, heavy versus light loads, and cold climate versus warm climate.5. Can the operator detect a misfire? This can lead you to a diagnosis of just one cylinder rather than an entire engine system.6. Does the engine smoke excessively, and if so, under what conditions? Excessive smoke can give indications about engine settings and engine internal conditions.7. Does oil consumption indicate excessive component wear? The answer to this question can give an indication about the condition of the piston rings and cylinder liners. These can effect the efficiency of the engine.

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. THERE ARE NO HARD AND FAST ANSWERS FOR THESE QUESTIONS. There are many different truck engine specifications and truck vehicle specifications which will provide acceptable results. There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly.1. Is there a particular operating condition when the complaint occurs? Low power and response complaints require different repairs. Complaints during shifting will be different from complaints of low power in certain speed ranges or in certain terrains.2. What are the customer's expectations for fuel mileage and power and why does he have those expectations? Comparisons to other trucks on the road often have many unseen variables. If comparison to others is the basis for the complaint, you must insure that the comparison is valid.3. What are the normal upshift and downshift rpm's? If the shift points are too high, find out why. If the driver is operating this way out of habit or because he is taught to drive that way, arrange for him to receive the Caterpillar driver training information. If his shift points are too high because of poor performance, you may be able to correct this in the engine.4. What are the normal routes and loads for the truck? You should be looking for the amount of city versus highway driving, versus mountainous, heavy versus light loads, and cold climate versus warm climate.5. Can the operator detect a misfire? This can lead you to a diagnosis of just one cylinder rather than an entire engine system.6. Does the engine smoke excessively, and if so, under what conditions? Excessive smoke can give indications about engine settings and engine internal conditions.7. Does oil consumption indicate excessive component wear? The answer to this question can give an indication about the condition of the piston rings and cylinder liners. These can effect the efficiency of the engine.