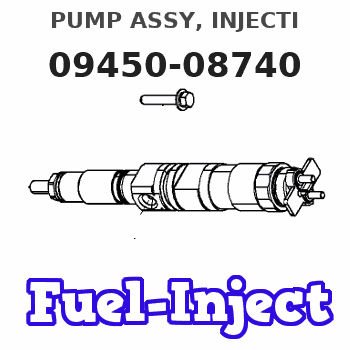

Information pump assy, injecti

Nozzle:

0935003840

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-08740 |

Scheme ###:

| 000. | [01] | 09450-08740 | PUMP ASSY, INJECTI | 30L6505900 |

| 001. | [01] | 09011-03730 | HOUSING SUB-ASSY, | |

| 002. | [03] | 09013-00390 | HOLDER SUB-ASSY, D | 47X0119800 |

| 003. | [03] | 09013-60530 | SPRING, DELIVERY V | |

| 004. | [03] | 09013-70130 | GASKET, DELIVERY V | |

| 005. | [03] | 09014-02110 | VALVE SUB-ASSY, IN | |

| 006. | [03] | 09015-06920 | ELEMENT SUB-ASSY, | 47X0123800 |

| 007. | [03] | 09016-00140 | SLEEVE SUB-ASSY, C | |

| 008. | [03] | 09016-30140 | SEAT, SPRING, UPR | |

| 009. | [03] | 09016-40220 | SPRING, PUMP PLUNG | MM501926 |

| 010. | [03] | 09016-50170 | SEAT, SPRING, LWR | |

| 011. | [03] | 09017-00220 | TAPPET SUB-ASSY,IN | |

| 012. | [01] | 09021-00560 | RACK ASSY, CONTROL | |

| 013. | [01] | 09024-40010 | SCREW, AIR BLEEDER | 09024-40010 |

| 014. | [01] | 09024-50310 | SCREW, HOLLOW | |

| 015. | [01] | 09024-80010 | WASHER, DRAIN SCRE | 09024-80010 |

| 016. | [02] | 09025-10010 | WASHER, INJECTION | 85265-00077 |

| 017. | [03] | 09018-30090 | PIN, INJECTION PUM | |

| 018. | [03] | 09023-00070 | PLATE SET, VALVE H | |

| 019. | [01] | 09069-11020 | BRACKET, STOP WIRE | |

| 020. | [02] | 94900-20500 | SCREW, COUNTERSUNK | |

| 021. | [03] | 94900-75390 | SCREW, W/WASHER | |

| 022. | [03] | 09013-90400 | O-RING | 47X0122600 |

| 023. | [01] | 09221-70480 | NIPPLE, SWIVEL | |

| 024. | [3C] | 09031-10400 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10410 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10420 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10430 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10440 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10390 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10380 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10370 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10360 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10350 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10340 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10330 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10320 | PLATE, TAPPET ADJU | |

| 024. | [3C] | 09031-10450 | PLATE, TAPPET ADJU |

Include in #3:

09450-08740

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-08740 | 30L6505900 | PUMP ASSY, INJECTI | |

| 30L6505900 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Cleanliness

Whenever hydraulic, fuel, lubricating oil or air lines are disconnected, clean the point of disconnection and the adjacent area. As soon as the disconnection is made, cap, plug or tape the line or opening to prevent entry of foreign material. The same recommendations for cleaning and covering apply when access covers or inspection plates are removed.Clean and inspect all parts. Be sure all passages and holes are open. Cover all parts to keep them clean. Be sure parts are clean when installed. Leave new parts in their containers until ready for assembly.Removal And Installation

Unless otherwise specified, all removals should be accomplished using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other and as near perpendicular as possible to the top of the object being lifted. When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt diminishes as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only have stress in tension. A length of pipe and a washer can be used, as shown, to help relieve these stresses on eyebolts.Forged eyebolts are available. Each size eyebolt has a maximum load recommendation.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.If a part resists removal, check to be certain all nuts and bolts have been removed and that an adjacent part is not interfering. Disassembly And Assembly

When assembling an engine, complete each step in turn. Do not partially assemble one part and start assembling some other part. Make all adjustments as recommended. Always check the job after it is completed to see nothing has been overlooked.Lubrication For A Rebuilt Engine

It is very important for a rebuilt engine to have "adequate" (needed) lubrication during the first seconds of operation. A "dry start" (without needed lubrication) on a rebuilt engine can cause bearing damage.When an engine is rebuilt with new parts, oil is put on each part as it is installed. This is generally enough lubrication for engine start-up. However, this lubrication may not be enough or may be lost if the rebuilt engine is placed in storage for any length of time.To prevent the possibility of a "dry start" and bearing damage during the first seconds of running, use the 1P540 Flow Checking Tool Group and shop air pressure to pressure lubricate (fill the main oil passage with oil under pressure) all rebuilt engines.Procedure for Pressure Lubrication

1. Clean the tank of the 1P540 Flow Checking Tool Group thoroughly, and set the pressure regulator to 35 5 psi (240 35 kPa).

Air pressure should not be more than 50 psi (345 kPa) at any time.

2. Put engine oil in the tank.3. Connect the tooling to the main oil passage of the engine.4. Add air pressure to the tank, with the regulator set at 35 5 psi (240 35 kPa). Although the tank does

Whenever hydraulic, fuel, lubricating oil or air lines are disconnected, clean the point of disconnection and the adjacent area. As soon as the disconnection is made, cap, plug or tape the line or opening to prevent entry of foreign material. The same recommendations for cleaning and covering apply when access covers or inspection plates are removed.Clean and inspect all parts. Be sure all passages and holes are open. Cover all parts to keep them clean. Be sure parts are clean when installed. Leave new parts in their containers until ready for assembly.Removal And Installation

Unless otherwise specified, all removals should be accomplished using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other and as near perpendicular as possible to the top of the object being lifted. When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt diminishes as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only have stress in tension. A length of pipe and a washer can be used, as shown, to help relieve these stresses on eyebolts.Forged eyebolts are available. Each size eyebolt has a maximum load recommendation.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.If a part resists removal, check to be certain all nuts and bolts have been removed and that an adjacent part is not interfering. Disassembly And Assembly

When assembling an engine, complete each step in turn. Do not partially assemble one part and start assembling some other part. Make all adjustments as recommended. Always check the job after it is completed to see nothing has been overlooked.Lubrication For A Rebuilt Engine

It is very important for a rebuilt engine to have "adequate" (needed) lubrication during the first seconds of operation. A "dry start" (without needed lubrication) on a rebuilt engine can cause bearing damage.When an engine is rebuilt with new parts, oil is put on each part as it is installed. This is generally enough lubrication for engine start-up. However, this lubrication may not be enough or may be lost if the rebuilt engine is placed in storage for any length of time.To prevent the possibility of a "dry start" and bearing damage during the first seconds of running, use the 1P540 Flow Checking Tool Group and shop air pressure to pressure lubricate (fill the main oil passage with oil under pressure) all rebuilt engines.Procedure for Pressure Lubrication

1. Clean the tank of the 1P540 Flow Checking Tool Group thoroughly, and set the pressure regulator to 35 5 psi (240 35 kPa).

Air pressure should not be more than 50 psi (345 kPa) at any time.

2. Put engine oil in the tank.3. Connect the tooling to the main oil passage of the engine.4. Add air pressure to the tank, with the regulator set at 35 5 psi (240 35 kPa). Although the tank does